CdS/ZnS-NiS nano-cluster photocatalyst and preparation method and application thereof

A photocatalyst and nano-cluster technology, which is applied in the field of photocatalysis, can solve the problems of insufficient contact between different components, limited contact, and unreasonable component distribution, and achieve the effect of improving utilization efficiency and improving hydrogen production performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] According to the method proposed by the present invention, a non-noble metal CdS / ZnS-NiS nanocluster photocatalyst with a nanoscale close contact interface is prepared:

[0047] (1) At room temperature, ultrasonically dissolve 1 mmol of cadmium acetate, 0.15 mmol of zinc acetate and 0.05 mmol of nickel acetate in 10 mL of deionized water to obtain a mixed precursor solution of Cd, Zn and Ni;

[0048] (2) Dissolve 3 mmol ethylenediamine and 2.5 mmol carbon disulfide in 20 mL deionized water at room temperature, and stir to obtain a uniform mixed solution.

[0049] (3) Add the precursor solution obtained in step (1) dropwise to the mixed solution obtained in step (2) under stirring to obtain a white turbid solution;

[0050] (4) Slowly heat the white turbid solution obtained in step (3) to 50° C. at a heating rate of 2° C. / min, and stir for 2 hours. The white turbid solution gradually turns into bright yellow;

[0051] (5) The bright yellow precipitate obtained in step (...

Embodiment 2

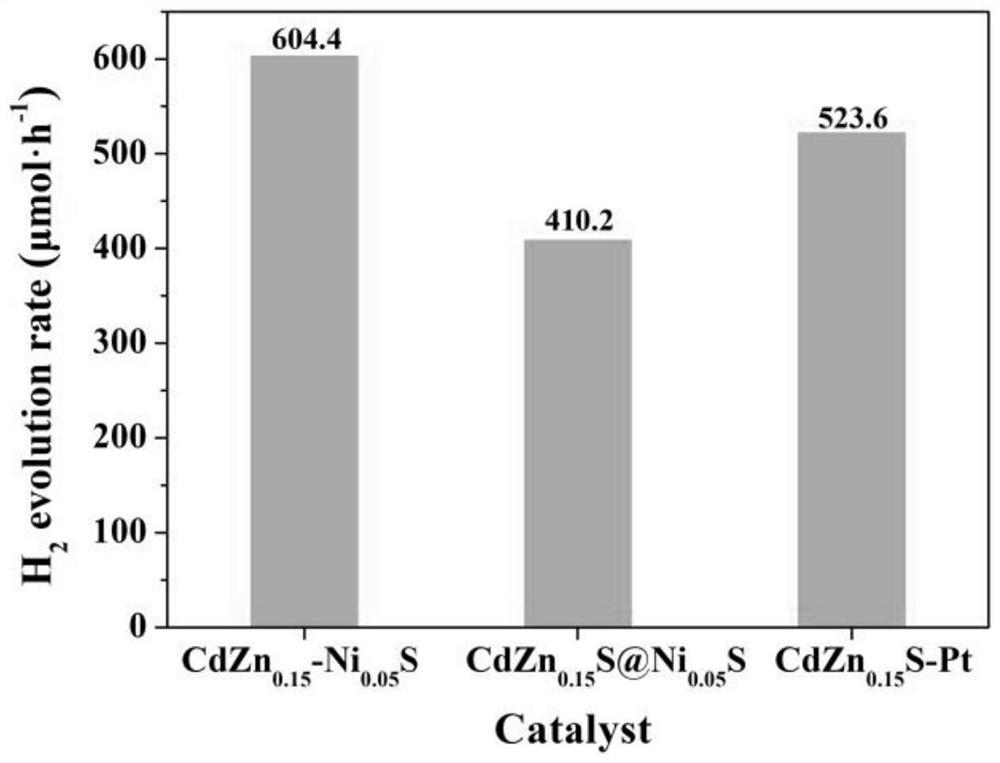

[0057] A non-noble metal CdS / ZnS-NiS nanocluster photocatalyst with a nanoscale close contact interface in the embodiment of the present invention, CdS, ZnS and NiS are uniformly distributed, and their molar ratio is Cd:Zn:Ni=1:0.15:0.025 , all the other are with embodiment 1. The photocatalytic hydrogen production activity of the catalytic system was 520.7μmol / h (10mg catalyst).

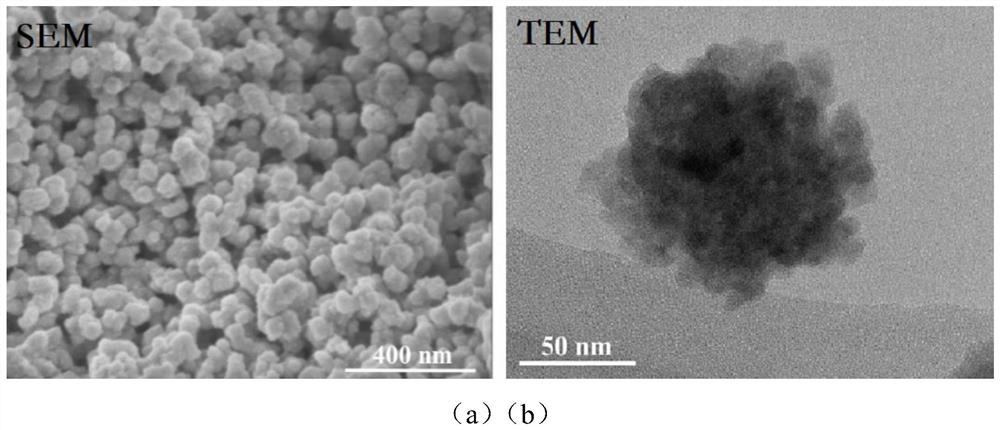

[0058] The image processing software Image J was used to measure and count the size of the catalyst prepared in this example step by step, and the size of the nanocluster catalyst was obtained to be 80-100 nm, and the size distribution of the nanoparticles constituting the nano-cluster was 3-5 nm.

Embodiment 3

[0060] A non-noble metal CdS / ZnS-NiS nanocluster photocatalyst with a nanoscale close contact interface in the embodiment of the present invention, CdS, ZnS and NiS are uniformly distributed, and their molar ratio is Cd:Zn:Ni=1:0.15:0.075 , all the other are with embodiment 1. The photocatalytic hydrogen production activity of the catalytic system was 473.3μmol / h (10mg catalyst).

[0061] The image processing software Image J was used to measure and count the size of the catalyst prepared in this example step by step, and the size of the nanocluster catalyst was obtained to be 80-100 nm, and the size distribution of the nanoparticles constituting the nano-cluster was 3-5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com