High-temperature-resistant halogen-free flame-retardant 3D printing photosensitive resin and preparation method thereof

A 3D printing, photosensitive resin technology, applied in the field of 3D printing materials, can solve the problems of poor flame retardancy and unsatisfactory effect, and achieve the effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

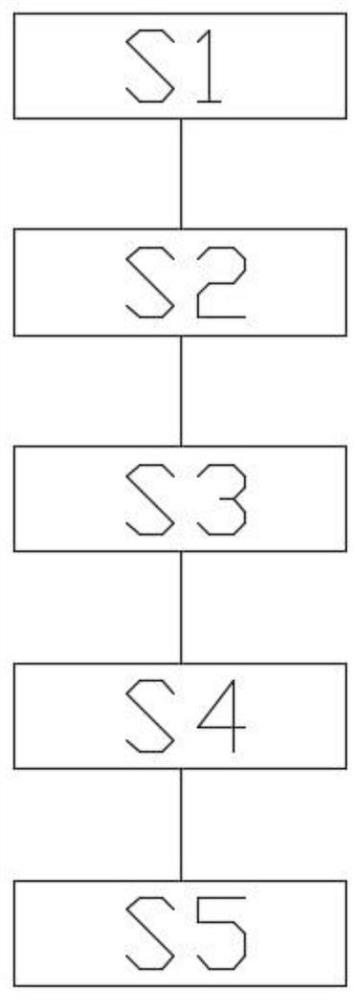

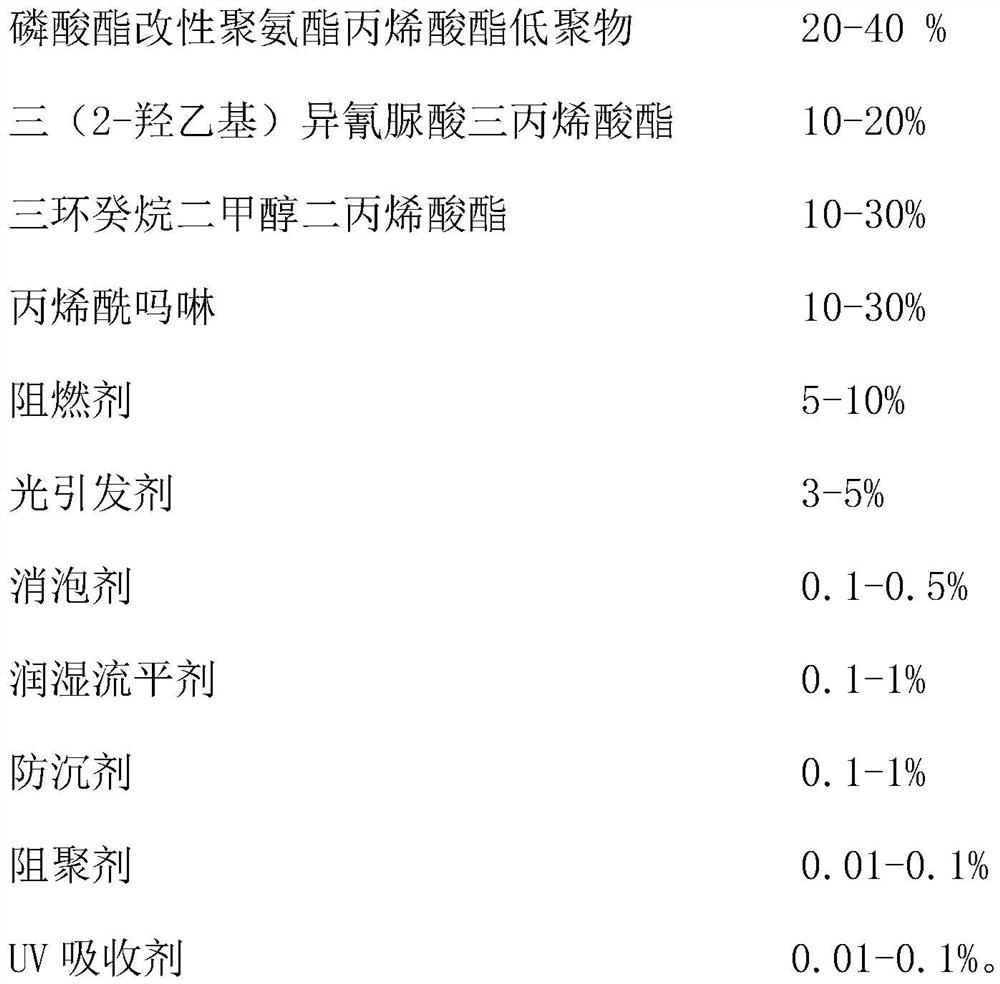

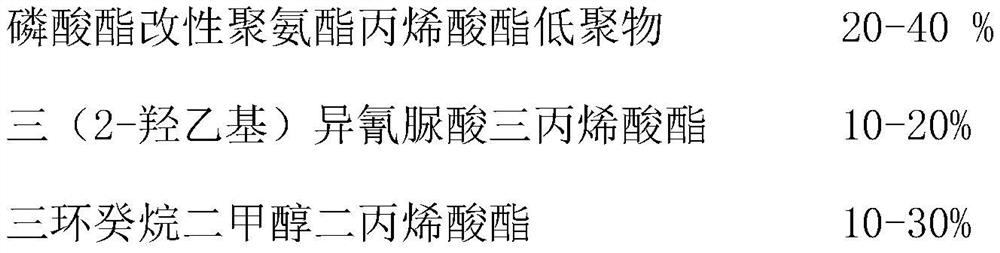

[0027] Such as figure 1 As shown, the present invention is a high-temperature-resistant halogen-free flame-retardant 3D printing photosensitive resin, which includes the following components in mass percentage:

[0028]

[0029]

[0030] The flame retardant is one or a combination of OP935, OP945, AP423, AP462.

[0031] The photoinitiator is one or a combination of 184, 1173, 369, ITX, TPO, 819.

[0032] The defoamer is one or a combination of BYK019, BYK1790, BYK535, BYK065 KS66.

[0033] The wetting and leveling agent is one or a combination of BYK333, BYK3570, BYK3720, BYK331.

[0034] The anti-settling agent is one or a combination of BYK410, BYK405, BYK420, BYK2009, BYK2013.

[0035] The polymerization inhibitor is one or a combination of HQ, PBQ, THQ, HQMME, MTBHQ.

[0036] The UV absorber is one or a combination of UV326, UV327, UV328.

[0037] A method for preparing a high-temperature-resistant halogen-free flame-retardant 3D printing photosensitive resin, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com