Glue, preparation method thereof and adhesive tape

A glue and tape technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem that packaging cartons cannot be reused, unfavorable cartons and tapes are recycled and reused, and can be peeled off Poor performance and other problems, to achieve the effect of enhancing peelability, improving peelability, and improving the phenomenon of glue rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation process for glue, comprising the following steps:

[0054] S1. Pre-drip preparation:

[0055] S1-1: Mix 15kg hydroxyethyl cellulose, 3kg organic bentonite and 8kg aliphatic mineral oil to prepare a mixed solution;

[0056]S1-2: Mix 25kg of emulsifier with 2000kg of water A, stir for 30 minutes, add 90kg of acrylic acid and 2.5kg of plasticizer, then add 6000kg of butyl acetate, stir, when butyl acetate is added to half, add the preparation in S1-1 The obtained mixed solution and the defoamer with a total amount of 6% of the defoamer added, the defoamer was dissolved in 15 times the mass multiple of water B and then added, and the stirring was continued for 40min to obtain the front drop feed;

[0057] S2, glue preparation:

[0058] S2-1: Mix the remaining amount of water A in the raw material with 5kg of sodium bicarbonate, add 15kg of pre-initiator-sodium persulfate when the temperature rises to 80°C, stir for 5min and then add the pre-dropping material...

Embodiment 2

[0065] A kind of preparation method of glue, carries out according to the method in embodiment 1, difference is:

[0066] S1. Pre-drip preparation:

[0067] S1-1: Mix 20kg of hydroxyethyl cellulose, 5kg of organic bentonite and 10kg of aliphatic mineral oil to prepare a mixed solution;

[0068] S1-2: Mix 30kg of emulsifier with 2200kg of water A, stir for 30 minutes, add 100kg of acrylic acid and 3kg of plasticizer, then add 6400kg of butyl acetate, stir, when the butyl acetate is added to half, add the preparation in S1-1 The obtained mixed solution and the antifoaming agent of 6% of the total addition amount of the antifoaming agent, the antifoaming agent is dissolved in the water B of 18 times of mass multiples and then added, and the stirring is continued for 40min to obtain the front dripping material;

[0069] S2, glue preparation:

[0070] S2-1: Mix the remaining water A in the raw material with 8 weight kg of baking soda, add 18kg of pre-initiator-sodium persulfate w...

Embodiment 3

[0077] A preparation process for glue is carried out according to the method in Example 1, the difference is that

[0078] S1. Pre-drip preparation:

[0079] S1-1: Mix 25kg of hydroxyethyl cellulose, 7kg of organic bentonite and 12kg of aliphatic mineral oil to prepare a mixed solution;

[0080] S1-2: Mix 35kg of emulsifier with 2500kg of water A, stir for 30 minutes, add 110kg of acrylic acid and 4.5kg of plasticizer, then add 6800kg of butyl acetate, stir, when butyl acetate is added to half, add the preparation in S1-1 The obtained mixed solution and the antifoaming agent of 6% of the total addition amount of the antifoaming agent, the antifoaming agent is dissolved in the water B of 20 times of mass multiples and then added, and the stirring is continued for 40min to obtain the front dripping material;

[0081] S2, glue preparation:

[0082] S2-1: Mix the remaining water A in the raw material with 10 weight kg of baking soda, add 18 kg of pre-initiator-sodium persulfate ...

PUM

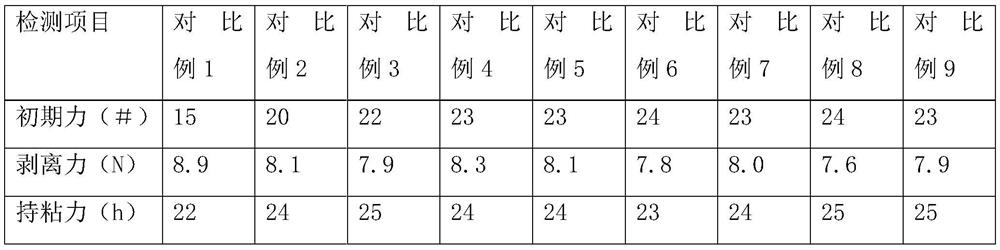

| Property | Measurement | Unit |

|---|---|---|

| Peel force | aaaaa | aaaaa |

| Stickiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com