Fixture and testing method for polymer cord/rubber interface fatigue performance test

A fatigue performance testing, polymer technology, used in the application of repetitive force/pulsation force to test the strength of materials, measuring devices, strength characteristics, etc., which can solve the evaluation of limited application, increased cord extraction life, and limited to static performance and other problems, to achieve the effect of uniform shear stress distribution, wide available frequency, and flexible test conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Step 1, take isoprene rubber 100phr, zinc oxide 5.0phr, stearic acid 2.0phr, antioxidant 4.0phr, carbon black N330 40.0phr, accelerator 1.6phr, vulcanizing agent 1.9phr, anti-coking agent 0.2phr, add isoprene rubber to the mixer, after mixing to get the parent rubber, move into the opener, add zinc oxide, stearic acid, antioxidant, carbon black, accelerator, vulcanizing agent and anti-coking agent, left and right cutting, thinning after the lower tablet, the thickness of the lower tablet is 2mm, Obtain the mixing rubber, park the mixing rubber at room temperature for 16h, and cut a number of 10×200mm rubber strips;

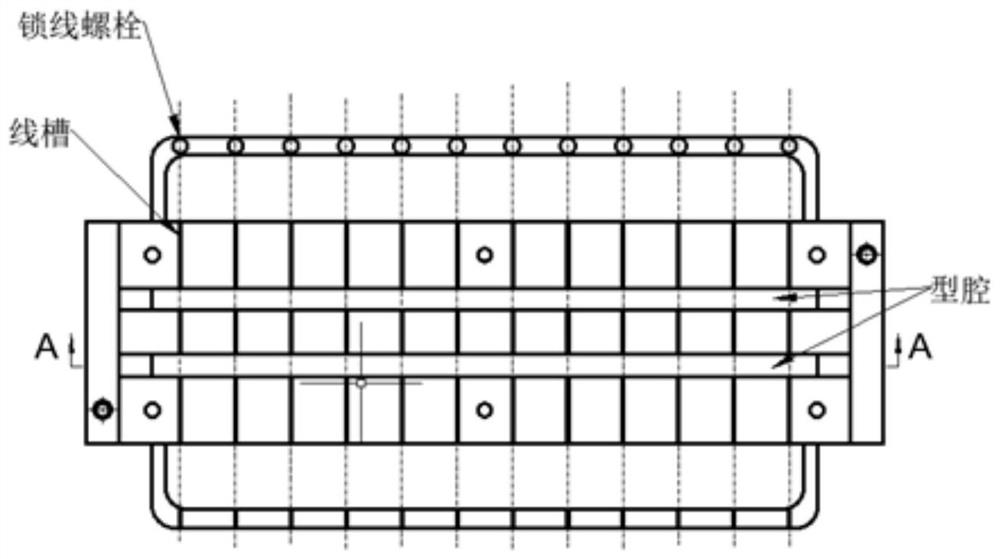

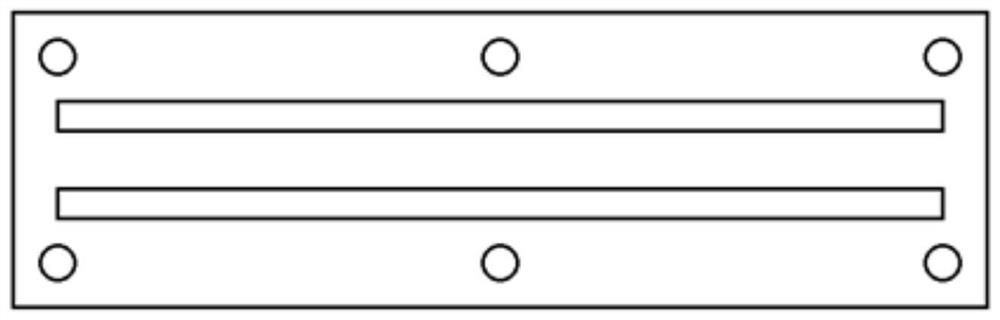

[0070] Step 2: Place two strips in the bottom model cavity of the vulcanization mold, lay 12 nylon 66 cords with a length of 400mm on the strips, with a specification of 1400dtex / 2, one end of each cord is bolted through the trunking, and the other end is bolted through the trunk and suspended with 50g weights;

[0071]Place the middle die on the bottom mold an...

Embodiment 2

[0076] Example 2 and the sample preparation process of Example 1 is the same, the difference is that in step three, the load amplitude is fixed to 50N, the fatigue cycle is set to 150,000 times, after the fatigue test is completed, the electronic fatigue testing machine is set to move upward at a speed of 50mm / min, and the residual extraction force of the single cord / rubber composite specimen is obtained is 86N.

Embodiment 3

[0078]Example 3 is the same as the sample preparation process of Example 1, the difference is that in step three, the load amplitude is fixed to 40N, the fatigue cycle is set to 150,000 times, after the fatigue test is completed, the electronic fatigue testing machine is provided to act as a moving cylinder at a speed of 50mm / min, and the residual extraction force of a single cord / rubber composite specimen is obtained is 112N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com