Vacuum heat treatment method for thin-film capacitor core

A film capacitor, vacuum heat treatment technology, applied in the direction of film/thick film capacitors, capacitors, capacitor manufacturing, etc., can solve the problems of reducing the service life of capacitors, low efficiency, high production noise, etc., to improve the air gap and internal stress, The effect of improving the uniformity of heating and the level of withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] to combine Figure 1-Figure 3 , a film capacitor core vacuum heat treatment method, comprising the following steps:

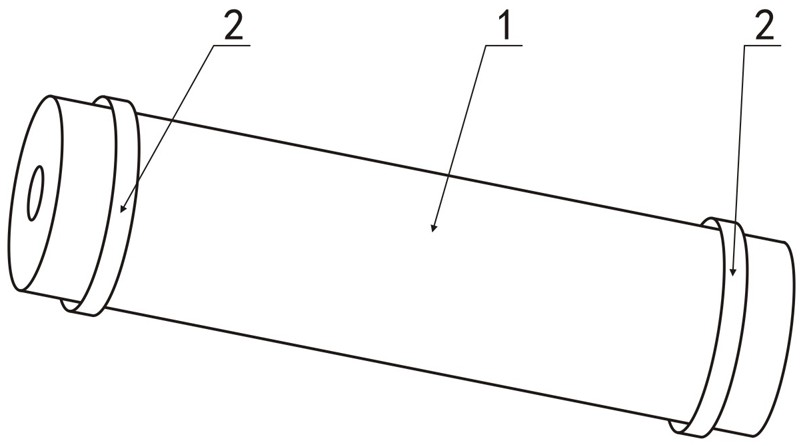

[0028] Step 1. Insulate the high temperature resistant rubber ring 2 on the position near the two ends of the film capacitor core 1;

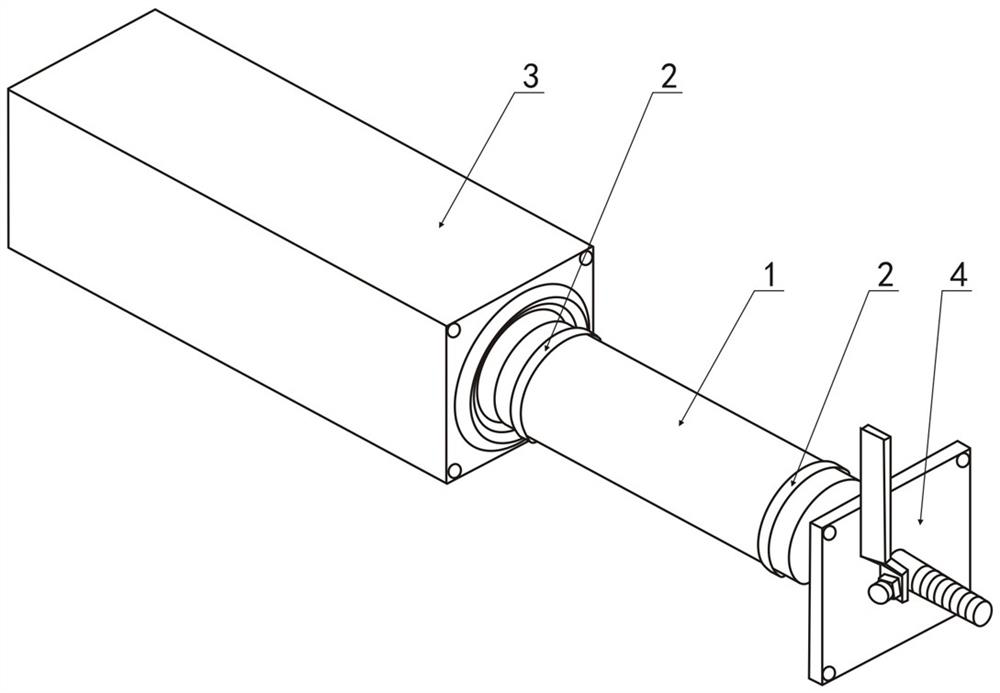

[0029] Step 2. Place the film capacitor core 1 with the rubber ring 2 in the core tank body 3 and seal it through the tank cover 4. The shape of the inner cavity of the core tank body is consistent with the shape of the film capacitor core and its inner diameter is greater than the outer diameter of the rubber ring; the core tank body 3 is a metal tank body and its inner wall is smooth; the film capacitor core 1 can be fixed by using the friction force between the outer wall of the rubber ring 2 and the inner cavity wall of the core tank body 3, Avoid direct contact between the film capacitor core 1 and the inner wall of the core tank 3;

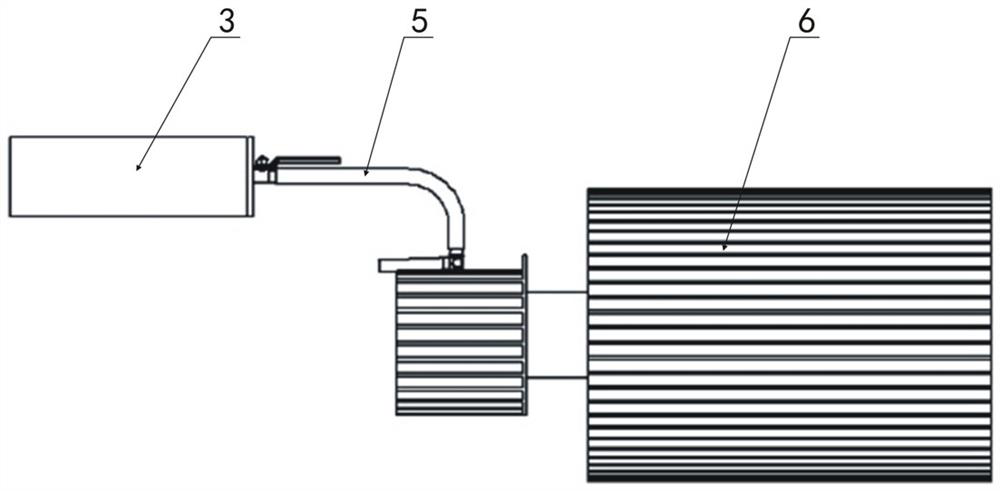

[0030] Step 3, use the vacuum pump 6 to evacuate the core tank body 3, and the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com