A mosfet chip manufacturing method for improving gate characteristics

A manufacturing method and chip technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as inability to effectively limit the current flowing through the gate, and achieve space-saving, high-performance, and reduced switching losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It is also to be understood that the terminology used in this specification is for the purpose of describing particular embodiments only

[0044] It should be further understood that the term "and / or" as used in this specification and the appended claims means

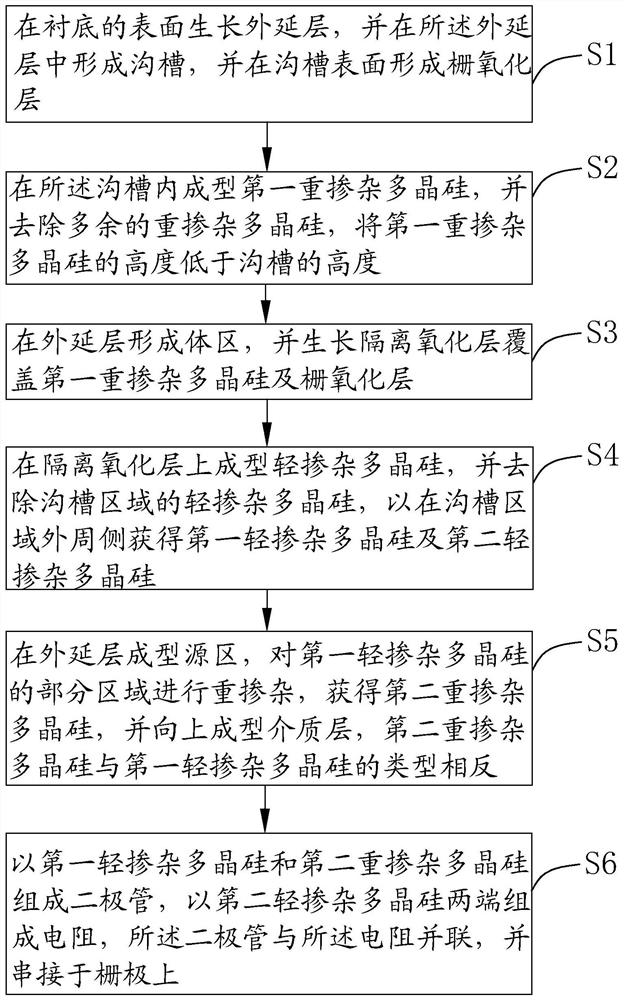

[0057] Specifically, the second heavily doped polysilicon 8.1 is implanted with boron atoms, or injected with ion implantation.

[0059] It can be understood that in step S6, holes are drilled through the first lightly doped polysilicon 8.2 and the second heavily doped polysilicon 8.1

[0061] Step S21: depositing initial polysilicon on the surface of the gate oxide layer in the trench region.

[0063] Step S23: using a dry etching process method to etch the first heavily doped polysilicon from top to bottom.

[0069] Step S63: forming a first metal connection line and a second metal connection line in the resistance contact hole, and the source region contacts

[0070] Step S64: forming a fourth metal connection and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com