Hollow-structure silicon-carbon negative electrode material and preparation method thereof

A negative electrode material and hollow technology, applied in the field of hollow structure silicon carbon negative electrode material and its preparation, can solve the problems of volume expansion, reduced cycle life, limited application of silicon carbon negative electrode, etc., and achieve the effect of alleviating expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

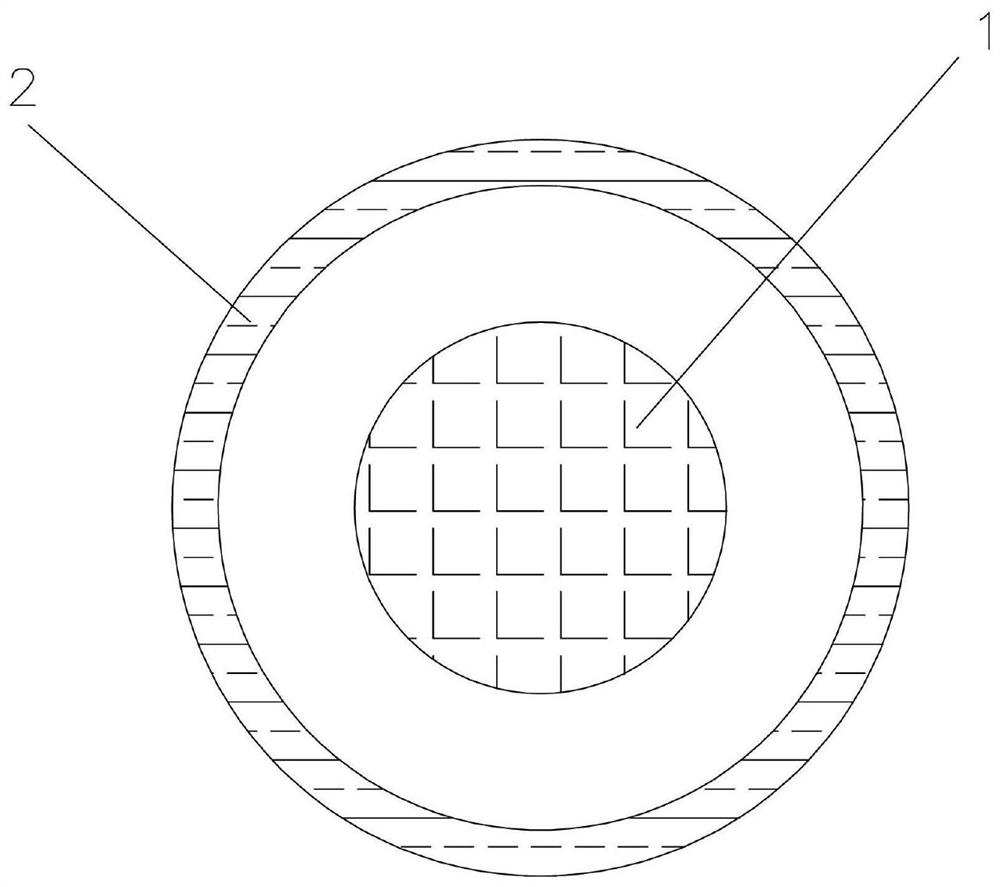

[0030] 2. A method for preparing a silicon-carbon negative electrode material with a hollow structure, comprising the following steps:

[0031] Step (A): dissolving the silicon core 1 in a metal solution, adding alkali to react, stirring, and centrifuging and washing with water to obtain the first composite particles of the silicon core 1 coated with metal deposits;

[0032] Step (B): Adding the composite particles to organic matter for condensation reaction under acidic conditions, centrifuging and washing with water to obtain the second composite particles with organic ester compound-coated silicon core 1;

[0033] Step (C): heating and calcining the second composite particle under the protection of an inert gas to graphitize the organic ester to form a graphene outer layer 2, and cooling to obtain the third composite particle;

[0034] Step (D): reacting the third composite particles under acidic conditions, removing the metal deposits to form a hollow layer, and obtaining ...

Embodiment 1

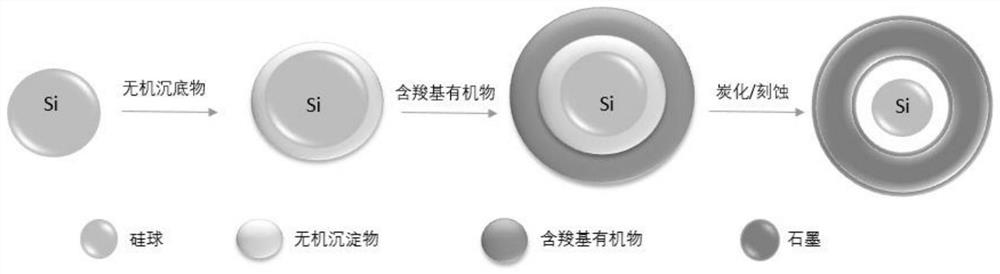

[0045] A method for preparing a hollow-structured silicon-carbon negative electrode material, such as figure 2 as shown,

[0046] 1. With SiH 4 Si pellets with a diameter of 20um, i.e. the silicon core 1, were prepared by high-temperature pyrolysis as a silicon source; the obtained Si pellets were dissolved in 15ml, 1mol / L ZnCl 2 solution, then slowly add 5mL concentrated ammonia water to Si and ZnCl 2 In the mixed solution, and constantly stirred, the obtained solution was centrifuged and washed with water to obtain Si / ZnO pellets, which were the first composite particles;

[0047] 3. The obtained Si / ZnO pellets and 2 mL of isopropanol stearate were mixed in H 2SO 4 The solution was reacted in a water bath at 80°C for 1 hour, and the solution was centrifuged and washed with water to obtain Si / ZnO@stearic acid isopropanol pellets, namely the second composite particles;

[0048] 4. The obtained Si / ZnO@stearic acid isopropanol pellets were calcined in a tube furnace for 2 ...

Embodiment 2

[0061] The difference from Example 1 is:

[0062] The diameter of the silicon core 1 is 40um.

[0063] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com