Low-carbon sintering system and process method

A sintering machine system and carbon sintering technology, applied in the field of low-carbon green sintering, can solve the problems of large coke/powdered coal consumption and high pollutant discharge, and achieve the reduction of pollutant content, reduction of sintering carbon content, low Effect of carbon/ultra-low carbon sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

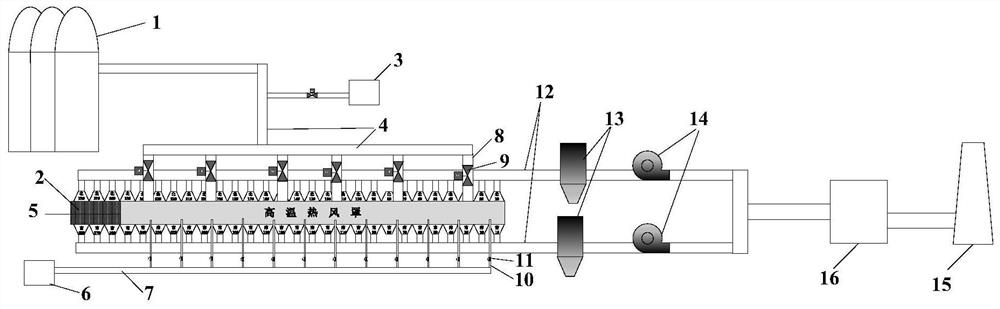

[0121] This embodiment provides a low-carbon sintering process, which is sintered by the above-mentioned method, and the process flow chart is as follows figure 1 shown. The details are as follows:

[0122] This embodiment is a 360m 2 Sintering machine 2, the raw material is iron ore powder mixture. Under traditional conditions, that is, the batching parameters under the condition of no hot air are shown in Table 1. The air volume required for traditional sintering is 25.5 million Nm 3 / h.

[0123] Table 1 Sintering ingredient parameter list under traditional conditions

[0124]

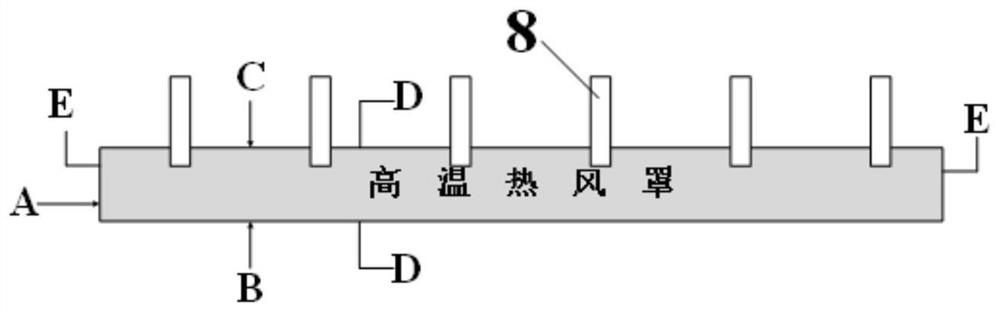

[0125] First, the air at normal temperature becomes 1000°C high-temperature air after passing through the hot blast stove 1; then the high-temperature air first passes through the hot blast main pipe 4, and then passes the high-temperature air into the high-temperature hot air cover 5 through six hot air branch pipes 8 connected to the hot blast main pipe, and then The high-temperature hot ai...

Embodiment 2

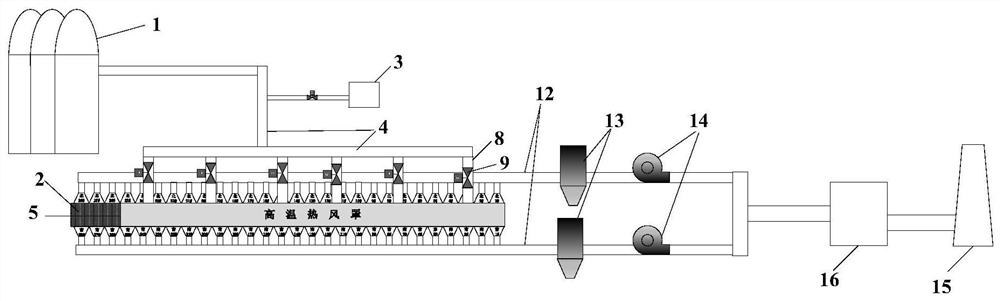

[0135] This embodiment provides a low-carbon sintering process, which is sintered by the above-mentioned method, and the process flow chart is as follows figure 2 shown. The details are as follows:

[0136] This embodiment is a 360m 2 Sintering machine 2, the raw material is iron ore powder mixture. Under traditional conditions, that is, the batching parameters under the condition of no hot air are shown in Table 3. The air volume required for traditional sintering is 25.1 million Nm 3 / h.

[0137] Table 3 Sintering batching parameter list under traditional conditions

[0138]

[0139] First, the air at normal temperature becomes 800°C high-temperature air after passing through the hot blast stove 1; then the high-temperature air first passes through the hot blast main pipe 4, and then passes the high-temperature air into the high-temperature hot air cover 5 through six hot-air branch pipes 8 connected to the hot-blast main pipe, and then The high-temperature hot air ...

Embodiment 3

[0148] This embodiment provides a low-carbon sintering process, which is sintered by the above-mentioned method, and the process flow chart is as follows figure 2 shown. The details are as follows:

[0149] This embodiment is a 360m 2 Sintering machine, the raw material is iron ore powder mixture. Under traditional conditions, that is, the batching parameters under the condition of no hot air are shown in Table 5. The air volume required for traditional sintering is 25.5 million Nm 3 / h.

[0150] Table 5 Sintering batching parameter table under traditional conditions

[0151]

[0152] Firstly, the air at normal temperature turns into high-temperature air at 1150°C after passing through the hot blast stove; then the high-temperature air passes through the hot-air main pipe first, and then passes the high-temperature air into the high-temperature hot-air hood through 6 hot-air branch pipes connected to the hot-air main pipe, and then the high-temperature hot air is sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com