Friction damping device, passive joint with same and surgical robot

A friction damping and joint technology, applied in the field of surgical robots, can solve the problems of permanent magnet brake release, complex structure and circuit, and achieve the effect of easy maintenance and replacement, and easy assembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

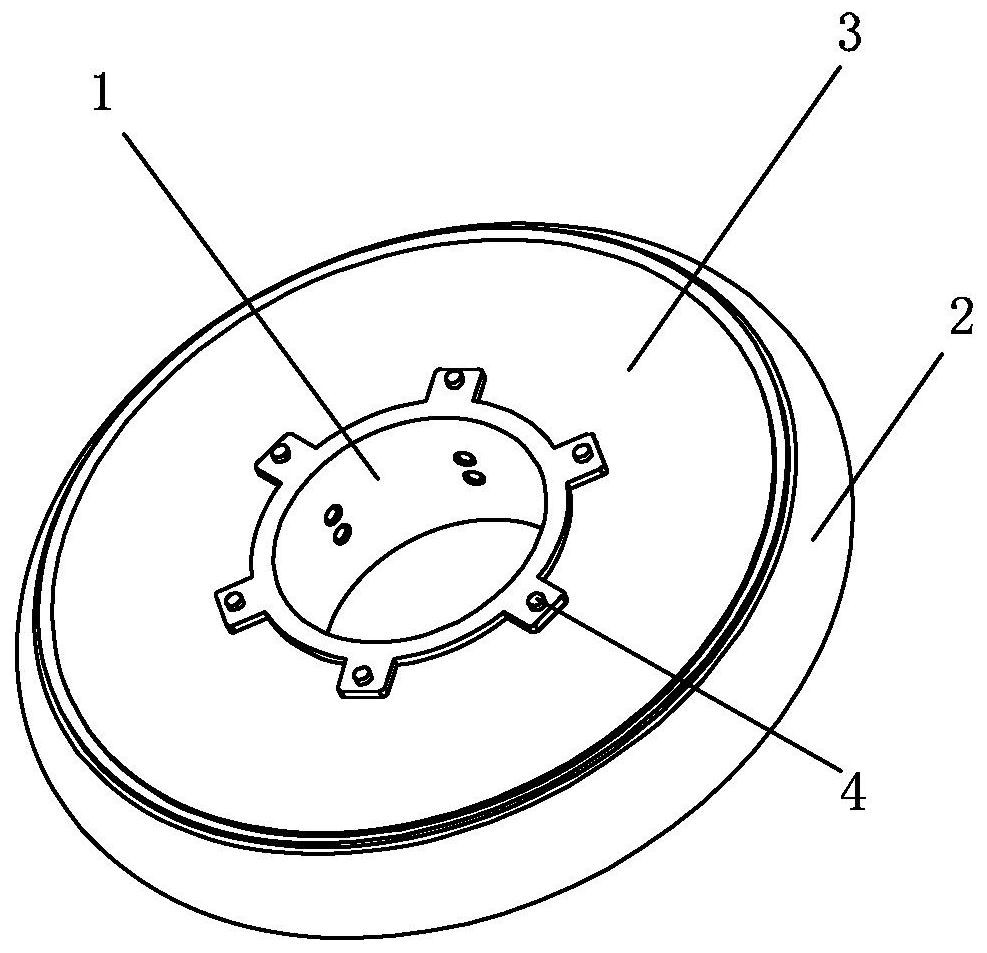

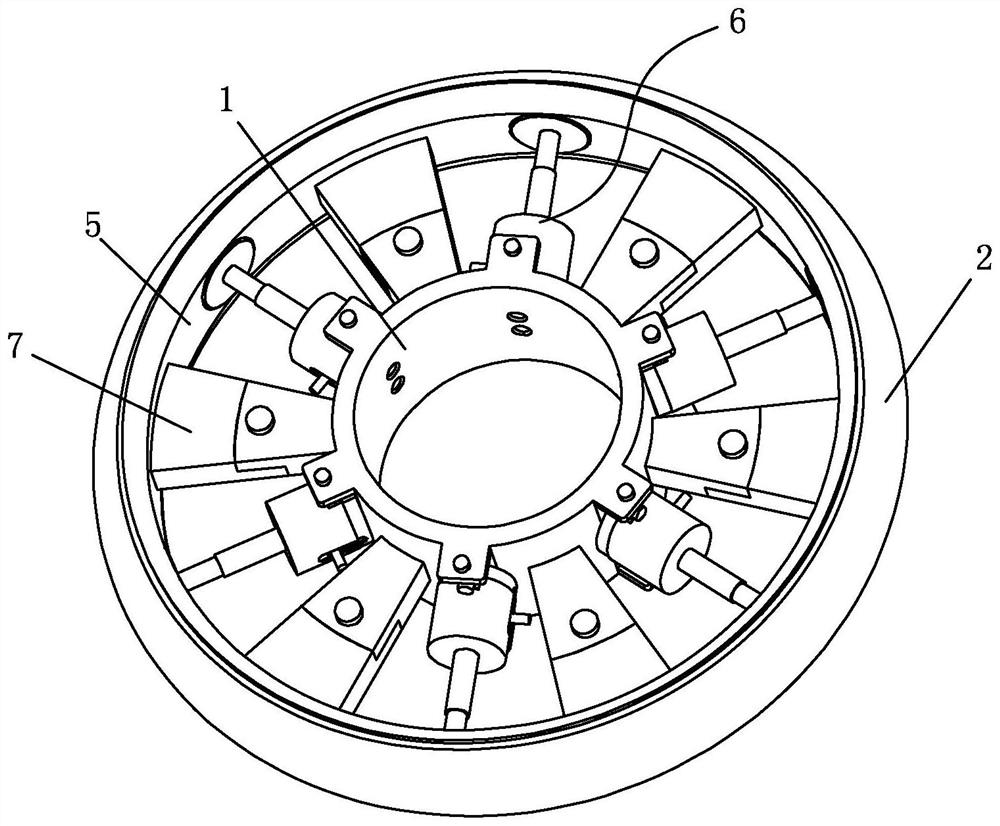

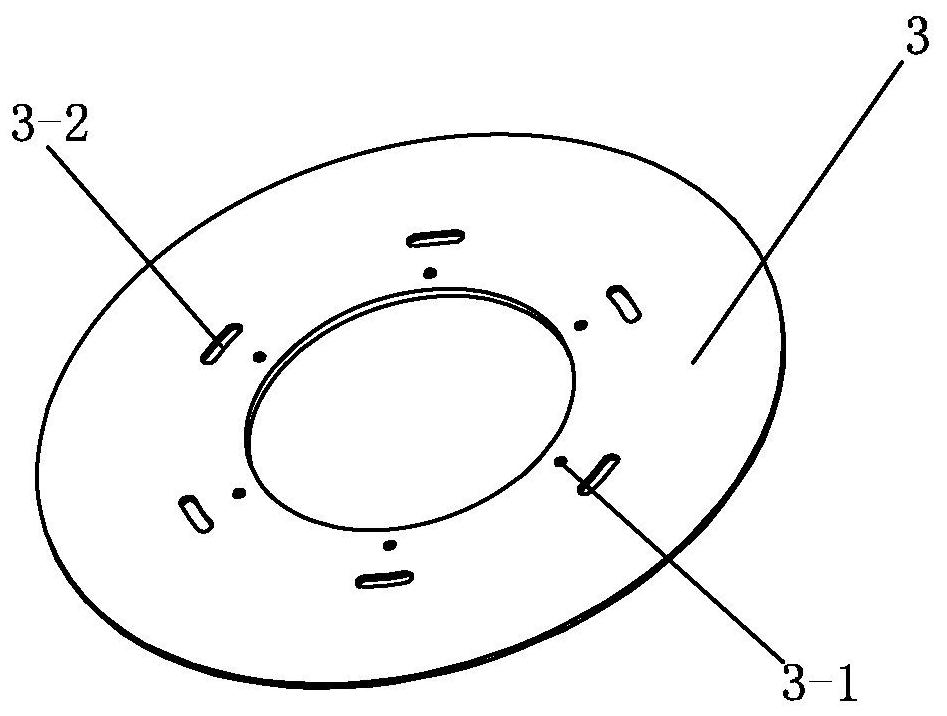

[0035] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, a friction damping device described in this embodiment includes a hollow shaft 1, a friction wheel 2, a hub 5, an actuator assembly 6 and a spoke assembly 7;

[0036] The hollow shaft 1 is arranged coaxially with the hub 5, and the hollow shaft 1 is provided with a plurality of spoke assemblies 7 along the outer surface of the circumference, and at least two actuator assemblies 6 are arranged between the plurality of spoke assemblies 7, and each actuator assembly 6. The bottom is fixedly connected with the outer wall of the hollow shaft 1. The hub 5 is provided with the same number of through holes as the actuator assemblies along the circumferential direction, and the top of each actuator assembly 6 is inserted into the through holes of the hub 5. The outer surface of the hub 5 A friction wheel 2 is sheathed on the surface;

[0037]In this specific embodiment, when in use,...

specific Embodiment approach 2

[0038] Specific implementation mode two: combination Figure 5 and Figure 6 Describe this embodiment. This embodiment is a further limitation on the damping device described in the first specific embodiment. In the friction damping device described in this embodiment, the actuator assembly 6 includes a force transmission unit and a force transmission unit. Sensor 6-8; one end of the force transmission unit abuts against the middle of the measuring end face of the force sensor 6-8, and the other end abuts against the friction wheel 2, which is used to transmit the external pressure received by the friction wheel 2 to the force sensor 6-8 to monitor the friction wheel 2 The amount of friction that can be provided;

[0039] In this specific embodiment, such a structure is adopted to improve the stability of the device during rotation.

specific Embodiment approach 3

[0040] Specific implementation mode three: combination Figure 5 Describe this embodiment. This embodiment is a further limitation on the damping device described in the second specific embodiment. In the friction damping device described in this embodiment, the force transmission unit includes a push rod 6-1, an upper Sleeve 6-2, lower sleeve 6-4, spring 6-5 and actuating rod 6-6;

[0041] The lower sleeve 6-4 is provided with an upper sleeve 6-2, and the center of the upper surface of the upper sleeve 6-2 is provided with a dowel bar, and the upper surface of the dowel bar is provided with a circular groove, and the groove The inside of the spring 6-5 is provided with a spring 6-5, and the top of the spring 6-5 is provided with an actuating rod 6-6, and the middle part of the upper surface of the actuating rod 6-6 is provided with a through hole, and the bottom of the push rod 6-1 is inserted as a The inside of the through hole on the upper surface of the moving rod 6-6;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com