Uraria crinita drying equipment with screening mechanism

A technology of drying equipment and timoth, which is applied in the direction of cutting equipment, drying solid materials, and dry cargo handling, etc. It can solve problems such as poor quality of forage, impossibility to screen out impurities such as stones, and the impact of timos drying process, etc., to achieve improvement Drying efficiency, effect of accelerating drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

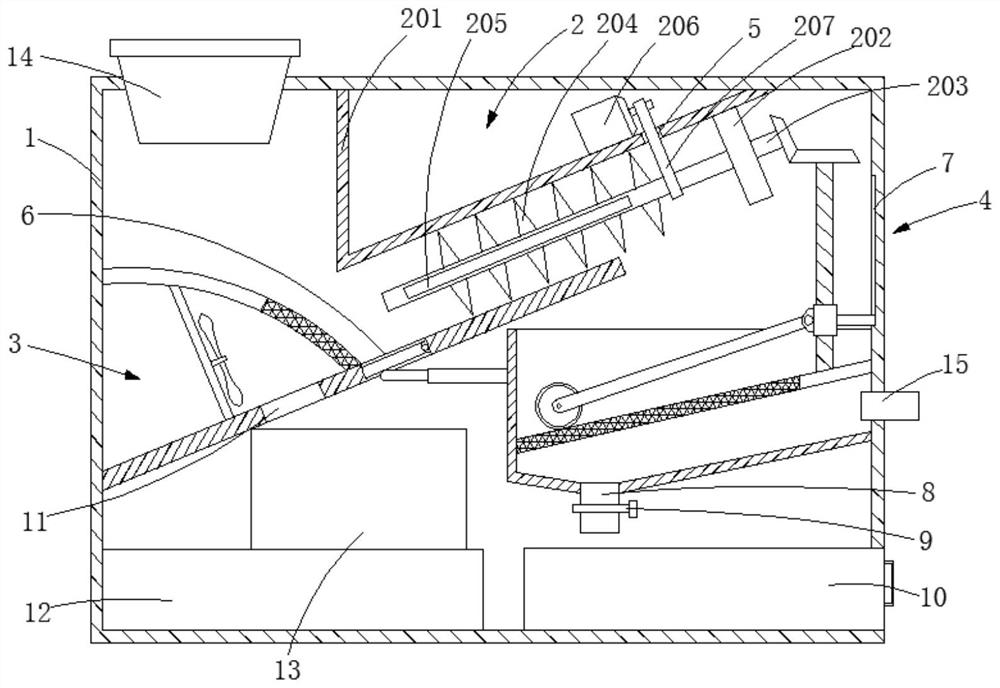

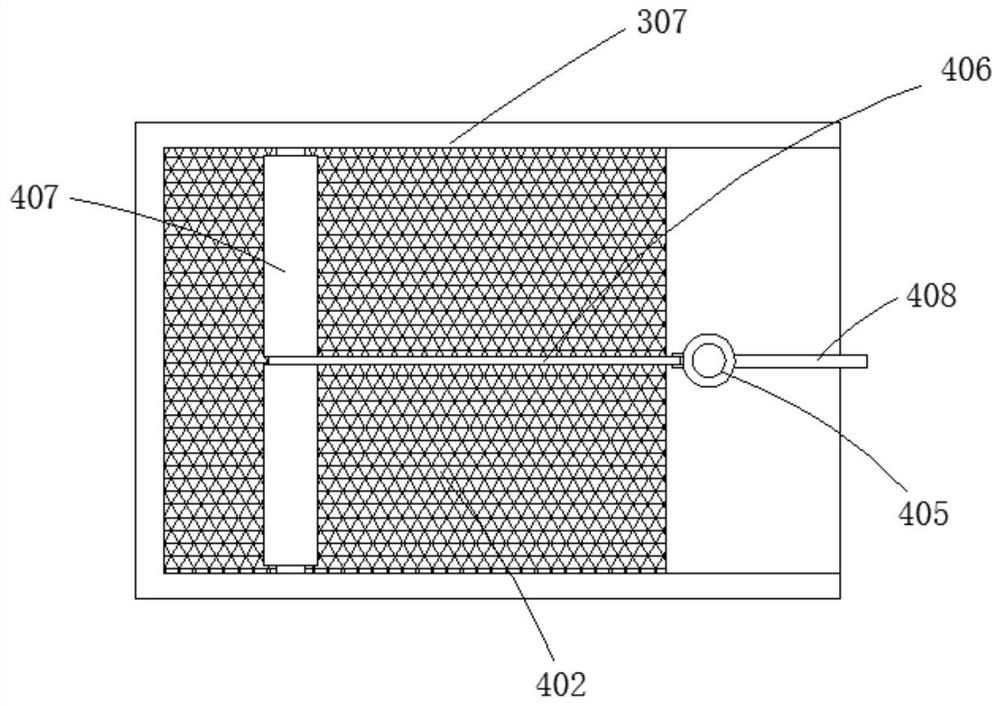

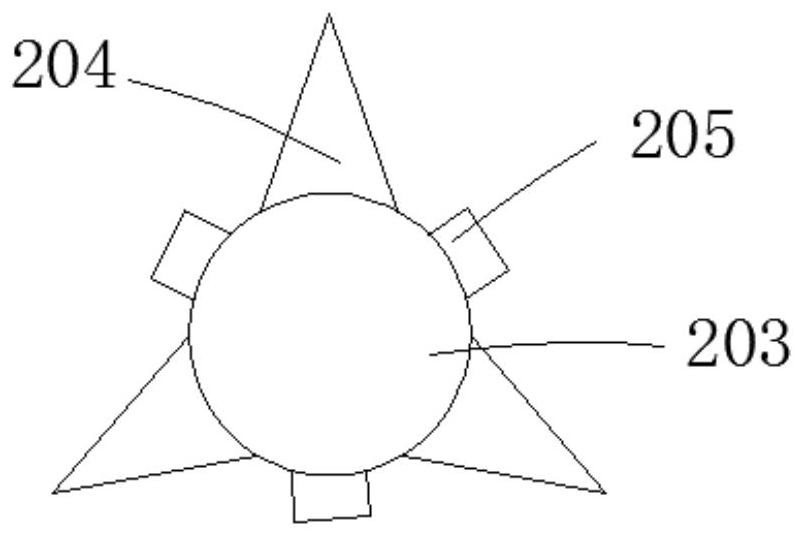

[0027] see Figure 1-5 , the present invention provides a technical solution: a timothy grass drying equipment with a screening mechanism, including a main body box 1, a crushing mechanism 2, a screening mechanism 3 and a crushing mechanism 4, and the crushing mechanism 2 includes a connecting platform 201, a support Rod 202, rotating rod 203, cutting blade 204, heating rod 205, servo motor 206 and transmission belt 207, the connection table 201 is fixedly connected to the top of the inner cavity of the main body box 1, and the bottom surface of the connection table 201 is inclined, and the support rod 202 is fixed On the bottom surface of the connection table 201, the rotating rod 203 is rotatably connected to the support rod 202, the cutting blade 204 is welded on the outside of the rotating rod 203, and the heating rod 205 is also installed on the rotating rod 203, and is spaced apart from the cutting blade 204. The motor 206 is installed in the inner cavity of the connecti...

Embodiment 2

[0034] Compared with embodiment 1, its difference is:

[0035] Wherein, the bottom of base plate 401 is provided with second blower fan 16, and the output end of second blower fan 16 is obliquely connected with air delivery pipe 17, and the second blower blower 16 that is set can assist the forage that falls to gather at the feeding pipe 8, so that enter The collection box 10 is more efficient.

Embodiment 3

[0037] Compared with embodiment 2, its difference is:

[0038] Wherein, the inner cavity of the glove box 13 is provided with an inclined platform 18, and the left side of the glove box 13 is communicated with a cleaning pipe 19, and the end of the cleaning pipe 19 extends to the outside of the main body box 1, from the discharge port 6 and the second The stone impurities falling from the discharge port 11 can directly roll into the cleaning pipe 19 from the inclined platform 18, thereby facilitating subsequent cleaning.

[0039] A specific application of this embodiment is: the device provides electric energy to the electrical components in the device through an external power supply, and controls their opening and closing through a control switch;

[0040] When in use, put the timoth into the main body box 1 from the feed port 14, the timoth will first fall on the arc plate 304, and gradually slide to the support plate 301 along the arc plate 304, and then open Fan 303, blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com