Design method of high-specific-energy lithium ion battery with both electrochemical performance and safety performance

A lithium-ion battery, safety performance technology, applied in electrochemical generators, material electrochemical variables, non-aqueous electrolyte storage batteries, etc., can solve problems such as difficult electrochemical performance and safety performance, and low development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Selecting: Select the material having an oxidative reducing activity under high voltage, the molecular formula is a layered structure of LINI x CO y M (1-x-y) O 2 Where x is greater than or equal to 0.8 less than 1, y <0.1, m is manganese Mn, vanadium V, ruthenium Ru and molybdenum moles, etc., with redox activity at high voltages, or has a certain interpretation capacity. If manganese-rich high-nickel material has a certain anion oxidation reduction reaction in a high voltage under feature, and molybdenum has a higher oxidative value.

[0032] Preparation: Prepare a lithium ion buckle battery, and activate 2-3 shampoo has stable electrochemical properties;

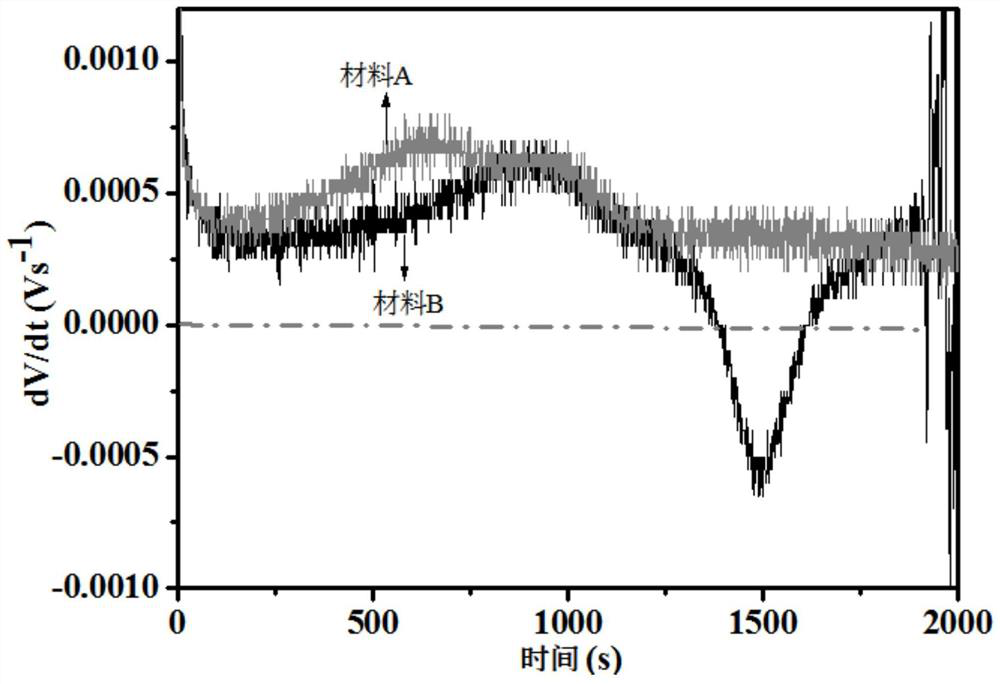

[0033] Evaluation: Verify the lithium ion buckle battery, evaluate the oxidative capacity and electrochemical properties of the materials to be evaluated:

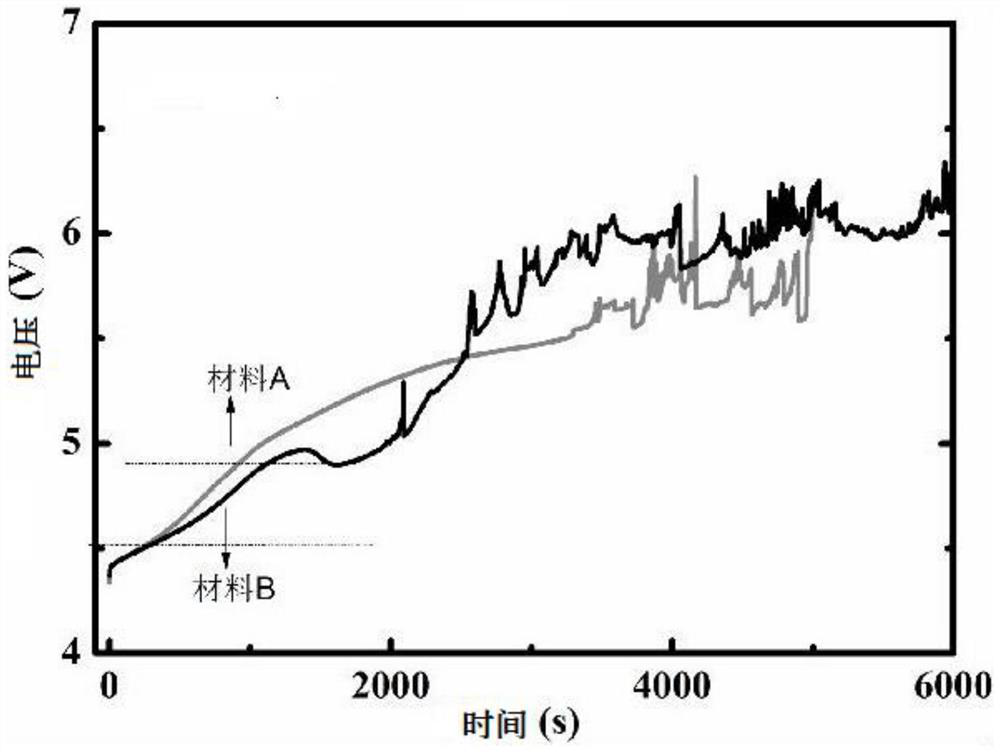

[0034] Lithium ion buckle batteries are over 6V at room temperature or high temperature 45-80 ° C;

[0035] Collect voltage V - time T curve to obtain differential...

Embodiment 2

[0044] The present example includes:

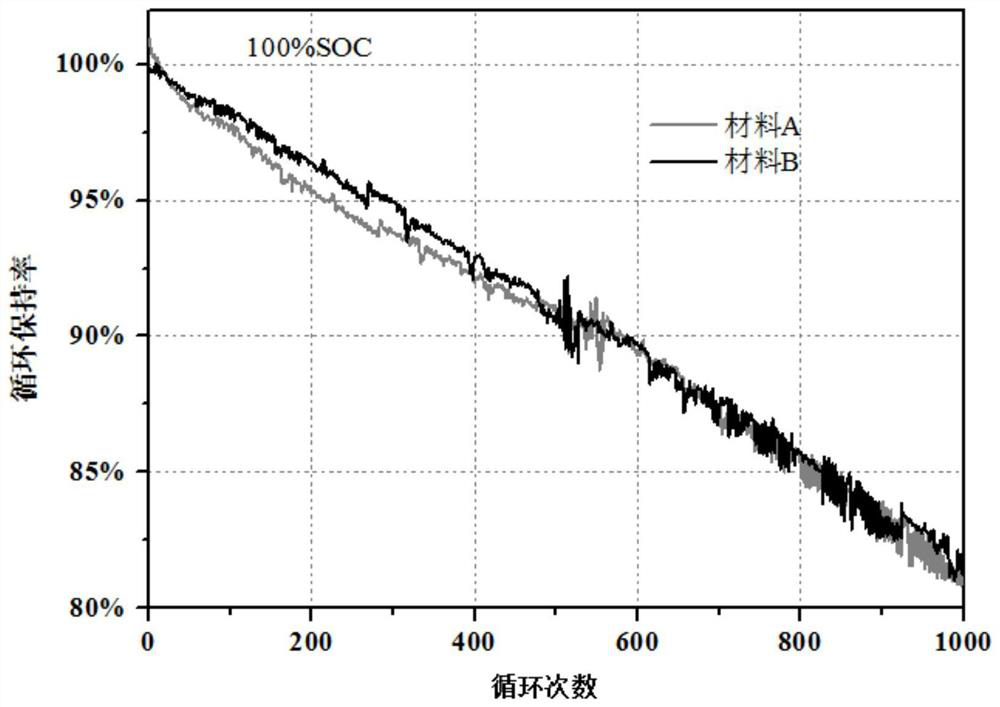

[0045] Selection: Select the positive material A (LINI) required to evaluate 0.8 CO 0.05 M 0.15 O 2 ), Under normal temperature conditions, have an oxidative capacity of anion oxygen under high pressure, and a sample positive material B (Lini 0.8 CO 0.1 Al 0.1 O 2 ) Basically, there is no high voltage redox capacity. At high temperatures, the oxygen activity of both is enhanced, and the known sample is also reflected. Both are high-nickel materials, and the nickel content is greater than 80%, with similar and higher specific capacity and similar crystal structures; it is known that both electrochemical properties on all-batteries are similar, electrochemical performance is excellent, two The loop life curve is as follows figure 1 Indicated.

[0046] The battery is prepared as follows: Preparation of the diaphragm polyethylene PE or polypropylene PP for the buckle battery is 16 microns; the electrolyte group is a certain proportion of vinyl ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com