Energy-saving low-consumption membrane-free aeration bioreactor

A technology of bioreactor and membrane aeration, applied to water pollutants, chemical instruments and methods, water/sludge/sewage treatment, etc. Solve the problems of large capital investment in the operation system to achieve the effect of improving the effective utilization rate, increasing the content of dissolved organic matter, and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

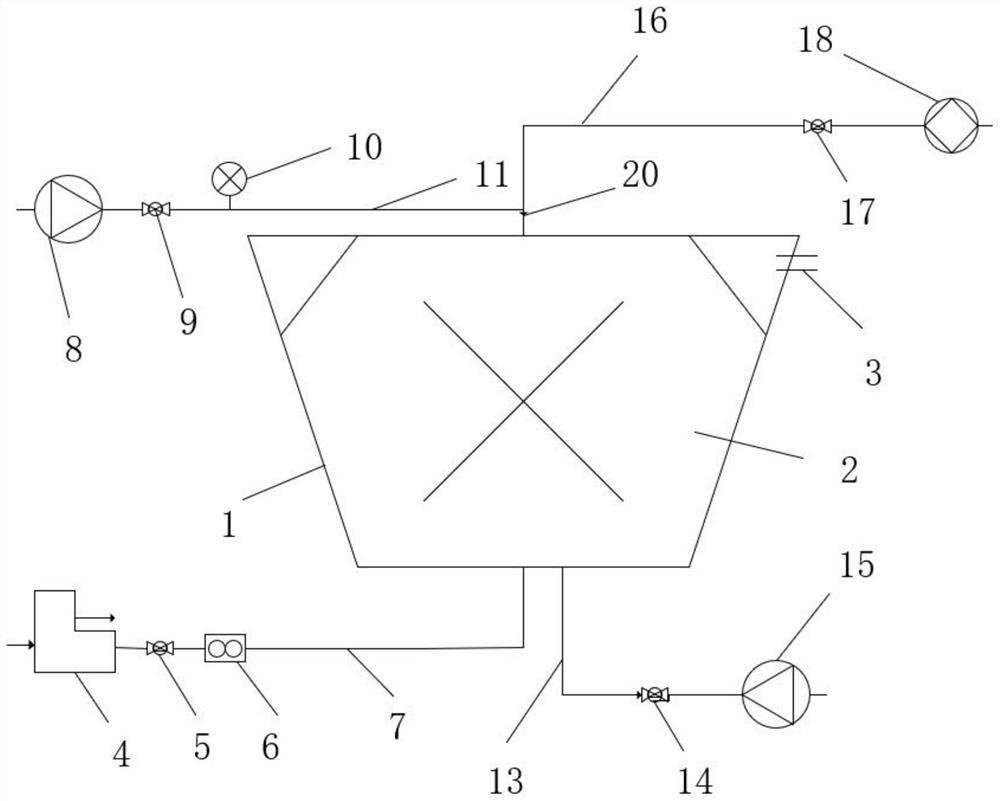

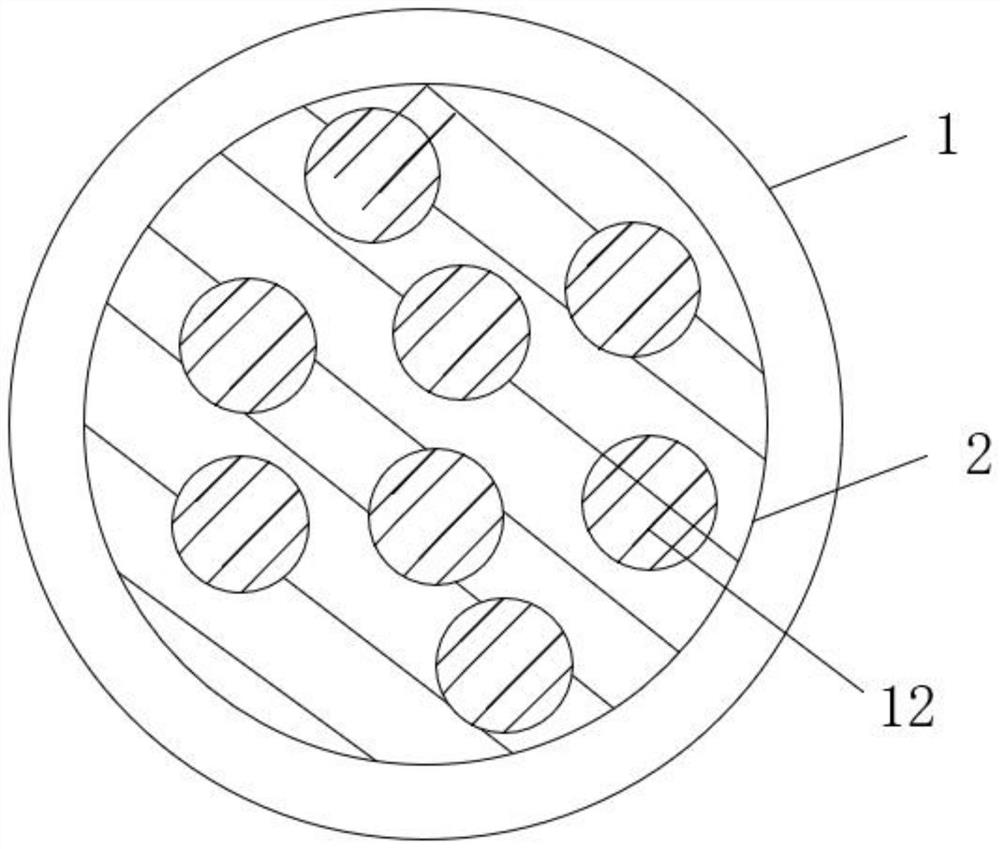

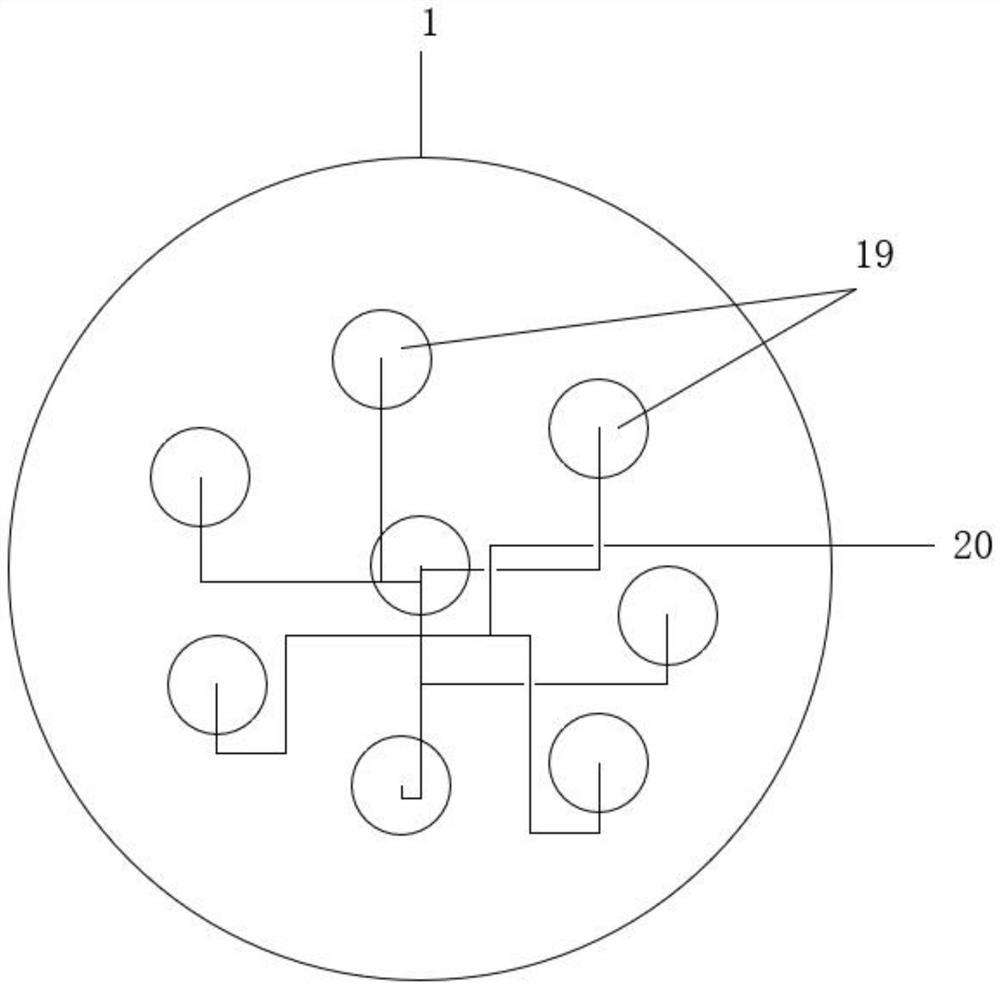

[0042] Embodiment 1: An energy-saving and low-consumption membraneless aerated bioreactor is characterized in that it includes: a reactor box (1), a porous filler (2), a water outlet (3), a feed pump (4), an air Compressor (8), aeration pan (12), air blower (15), water supply pump (18), micro-nano aeration pan (19), gas-water mixing pipeline (20); the feed pump (4) passes The water inlet pipe (7) communicates with the box body (1); the water inlet pipe (7) is connected with a ball valve (5) and a flow meter (6); The water mixing pipeline (20) is connected; the pipeline (11) is connected with a valve (9) and a pressure gauge (10); the water supply pump (18) is connected to the air-water mixing pipeline (20) through the water inlet pipe (16) connected, the water inlet pipe (16) is connected with a regulating valve (17); the gas-water mixing pipeline (20) is connected with the micro-nano aeration disc (19); the blower (15) is connected with the aeration disc ( 12) Connect throug...

Embodiment 2

[0052] Embodiment 2: An energy-saving and low-consumption membrane-free aerated bioreactor is characterized in that it comprises: a reactor box (1), a porous filler (2), a water outlet (3), a feed pump (4), an air Compressor (8), aeration pan (12), air blower (15), water supply pump (18), micro-nano aeration pan (19), gas-water mixing pipeline (20); the feed pump (4) passes The water inlet pipe (7) communicates with the box body (1); the water inlet pipe (7) is connected with a ball valve (5) and a flow meter (6); The water mixing pipeline (20) is connected; the pipeline (11) is connected with a valve (9) and a pressure gauge (10); the water supply pump (18) is connected to the air-water mixing pipeline (20) through the water inlet pipe (16) connected, the water inlet pipe (16) is connected with a regulating valve (17); the gas-water mixing pipeline (20) is connected with the micro-nano aeration disc (19); the blower (15) is connected with the aeration disc ( 12) Connect thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com