Corrosion inhibition material and application thereof

A corrosion-inhibiting material and coating technology, applied in the field of nano-composite materials, can solve the problems of poor sensitivity of halloysite nanotubes and unsatisfactory anti-corrosion performance of halloysite nanotube coatings, and achieve significant pH environmental change sensitivity, Strong environmental pH sensitivity and good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of halloysite nanotube coating comprises the following steps:

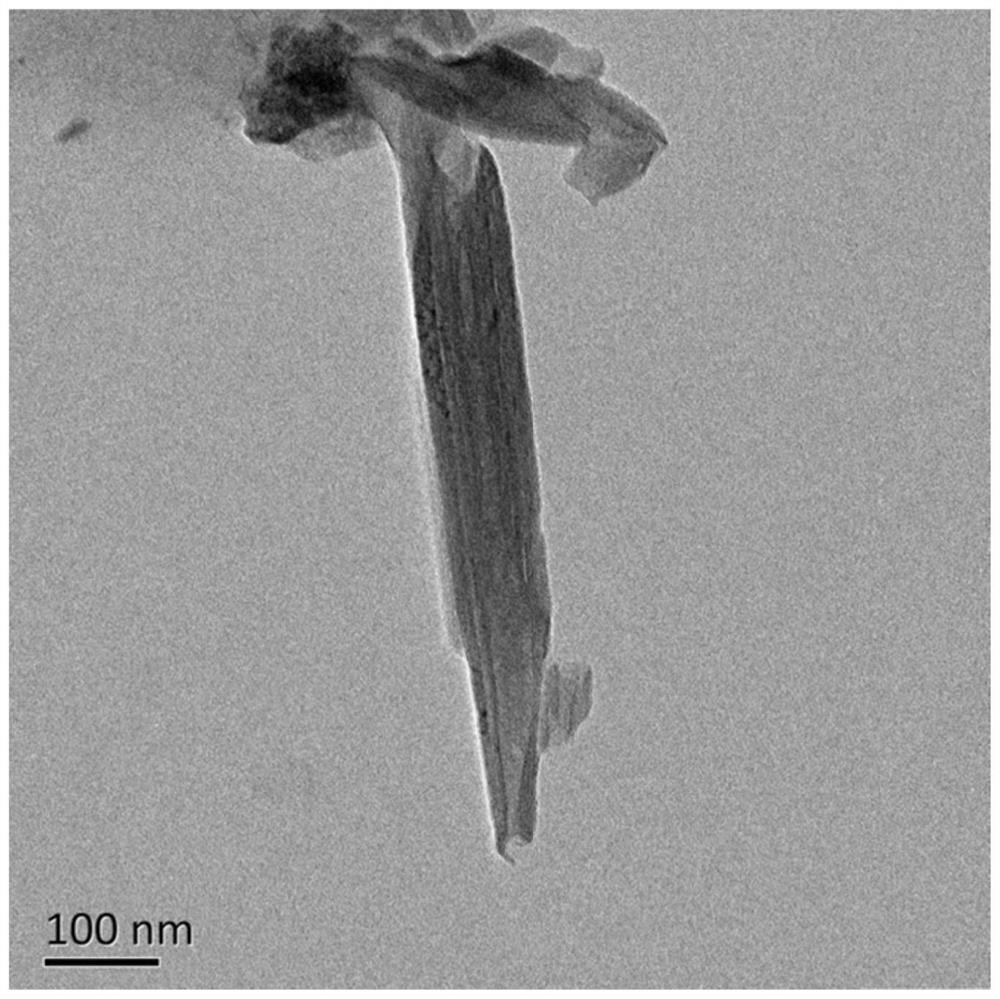

[0050] S1. Preparation of sodium lignosulfonate / halloysite nanotubes (SLS / HNTs)

[0051] Mix sodium lignosulfonate and halloysite nanotubes evenly in proportion, load sodium lignosulfonate into halloysite nanotubes by vacuum negative pressure, perform solid-liquid separation after centrifugation, wash and dry, and then grind to powder. Sodium lignosulfonate / halloysite nanotube powder was prepared.

[0052] Specifically, when sodium lignosulfonate / halloysite nanotubes are loaded under vacuum negative pressure, the mixed solution of sodium lignosulfonate and halloysite nanotubes is placed in a vacuum drying oven to evacuate the interior to vacuum. The density reaches 0.1MPa, load sodium lignosulfonate into halloysite nanotubes by negative pressure, make the vacuum box in a vacuum state for 2 hours, then open the air holes, let the outside air enter the vacuum box, repeat the above two st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com