Polyacetal resin composition and method for producing polyacetal resin composition

A technology of polyacetal resin and manufacturing method, applied in the field of polyacetal resin composition, capable of solving problems such as residual polymerization stability and difficulty in controlling polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

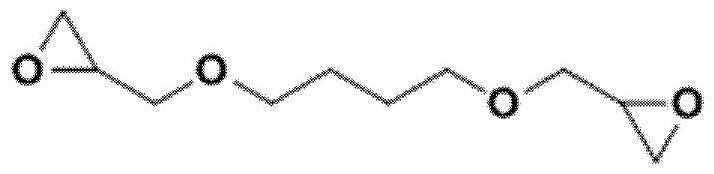

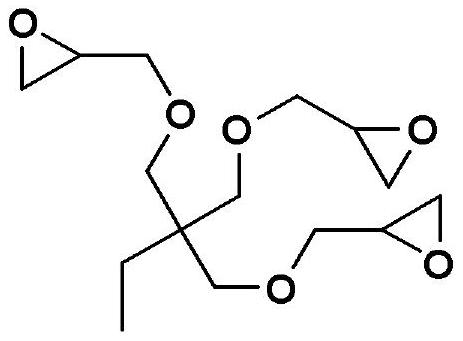

Image

Examples

Embodiment

[0092] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these.

[0093] The polyacetal resin (A) and polyacetal copolymer (B) used in Examples and Comparative Examples are as follows.

[0094]

[0095] The polyacetal resin was prepared as follows.

[0096] In a twin-screw paddle-type continuous polymerizer, 96.7% by mass of trioxane (TOX), 3.3% by mass of 1,3-dioxolane (DO) and 800 ppm of methylal were continuously supplied. The mixture was polymerized by adding 20 ppm of boron trifluoride as a catalyst.

[0097] The polymer discharged from the outlet of the polymerizer was immediately added to an aqueous solution containing 1000 ppm of triethylamine, pulverized and stirred to deactivate the catalyst. Next, the polymer is recovered by centrifugation and dried to obtain a polyacetal resin.

[0098]

[0099] The polyacetal copolymer (B) was prepared as follows.

[0100] In a closed autoclave with a jacket and a sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com