C5 petroleum resin hydrogenation catalyst and preparation method thereof

A C5 petroleum resin and hydrogenation catalyst technology, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low hydrogenation activity of catalysts, and achieve the goal of improving hydrogenation activity and promoting dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

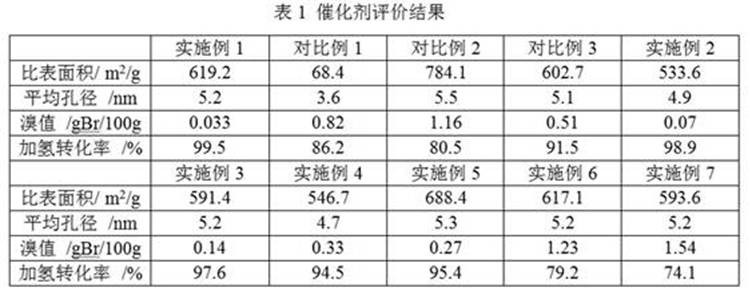

Examples

Embodiment 1

[0021] 1. Catalyst preparation

[0022] Weigh 40 g Ta 2 o 5 and 40 g of MCM-41 molecular sieve powder, the two carrier component powders were first calcined in a muffle furnace at 400 °C for 4 hours in an air atmosphere to remove flammable impurities. Weigh the 30 gTa after the above-mentioned roasting respectively 2 o 5 The powder is ground with 6 g of MCM-41 molecular sieve powder to form a solid-phase composite carrier powder. Weigh 8.92 g of nickel nitrate hexahydrate and 0.14 g of stannous chloride dihydrate, dissolve them in 30 ml of deionized water, and after they are uniformly dissolved, add the composite carrier powder in (2) above into the mixed salt solution, After stirring for 4 hours, it was transferred to an oil bath at 90 °C to evaporate the water to dryness, and the obtained catalyst powder impregnated with active components was roasted in a muffle furnace at 400 °C for 4 hours to obtain 5 wt%Ni-0.02 wt%Sn / 20wt% MCM-41-80wt%Ta 2 o 5 .

[0023] The above...

Embodiment 2

[0045] 1. Catalyst preparation

[0046] Weigh 40 gTa 2 o 5 and 40 g of SBA-15 molecular sieve powder, the two carrier component powders were first calcined in a muffle furnace at 400 °C for 4 hours in an air atmosphere to remove flammable impurities. Weigh the 30 gTa after the above-mentioned roasting respectively 2 o 5 The powder is ground with 6 g of SBA-15 molecular sieve powder to form a solid-phase composite carrier powder. Weigh 8.92 g of nickel nitrate hexahydrate and 0.14 g of stannous chloride dihydrate, dissolve them in 30 ml of deionized water, and after they are uniformly dissolved, add the composite carrier powder in (2) above into the mixed salt solution, After stirring for 4 hours, it was transferred to an oil bath at 90 °C to evaporate the water to dryness, and the obtained catalyst powder impregnated with active components was roasted in a muffle furnace at 400 °C for 4 hours to obtain 5 wt%Ni-0.02 wt%Sn / 20wt% SBA-15-80wt%Ta 2 o 5 .

[0047] The above-...

Embodiment 3

[0051] 1. Catalyst preparation

[0052] Weigh 40 g Ta 2 o 5 and 40 g of MCM-41 molecular sieve powder, the two carrier component powders were first calcined in a muffle furnace at 400 °C for 4 hours in an air atmosphere to remove flammable impurities. Weigh the 30 g Ta after the above-mentioned roasting respectively 2 o 5 The powder is ground with 6 g of MCM-41 molecular sieve powder to form a solid-phase composite carrier powder. Weigh 8.92 g of nickel nitrate hexahydrate and 0.013 g of lead acetate trihydrate, dissolve them in 30 ml of deionized water, and after they are uniformly dissolved, add the composite carrier powder in (2) above into the mixed salt solution, and stir for 4 hours , and then transferred to a 90 °C oil bath to evaporate the water to dryness, and the obtained catalyst powder impregnated with active components was placed in a muffle furnace at 400 °C for 4 hours to obtain 5 wt%Ni-0.02 wt%Pb / 20wt%MCM-41 -80wt%Ta 2 o 5 .

[0053] The above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com