Pipeline noise control device and method based on local resonance mechanism acoustic metamaterial

An acoustic metamaterial, local resonance technology, applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/fittings, etc., can solve too many additional equipment, change the original flow field in the pipe, and the subsequent modes cannot be controlled, etc. problems, to achieve the effect of fewer additional devices, fewer components, and significant design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

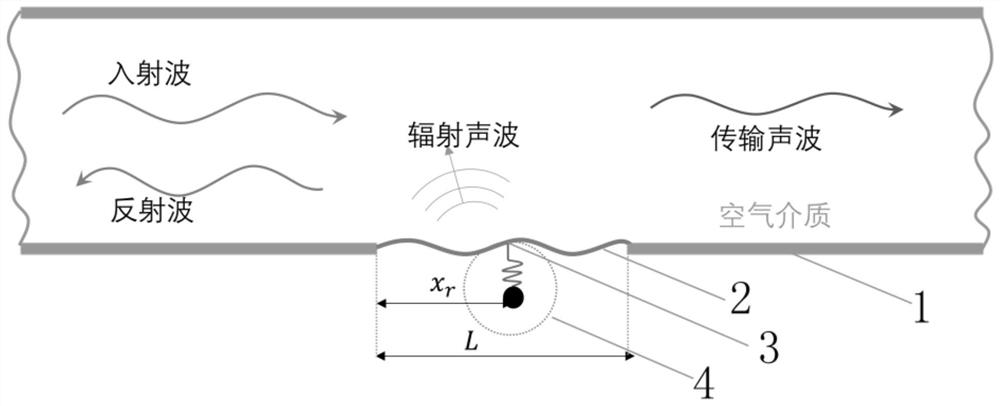

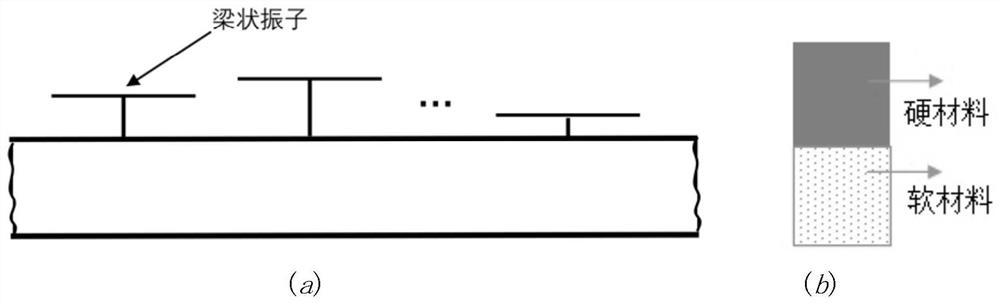

[0034] refer to figure 1 , 2, 3, a pipe noise silencing device based on the principle of local resonance, the main technical feature is that a flexible film 2 is embedded in the side wall of the pipe 1, and a plurality of small spring vibrators 4 are applied to the flexible film 2. The frequency of noise reduction changes the structural parameters, and the noise at this frequency is eliminated by using the local resonance mechanism. Concrete implementation scheme is as follows:

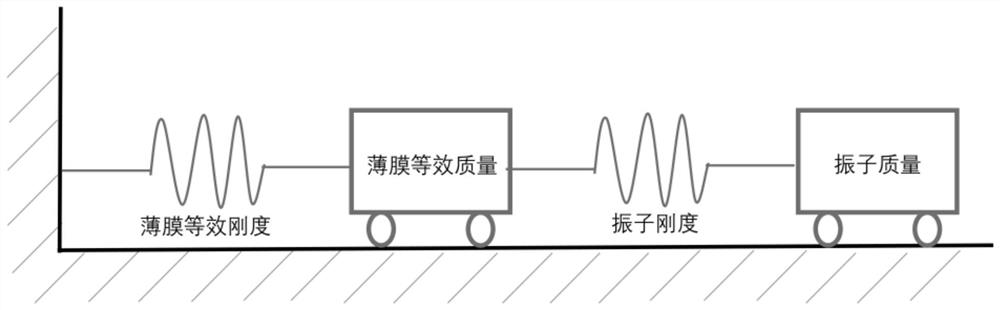

[0035] In the thin film acoustic metamaterial muffler structure designed by the present invention, there is a pipeline 1; the pipeline is assumed to be a square tube, and the original rigid wall is replaced with a flexible membrane 2 on the side of the pipeline, and a spring vibrator 4 is attached to the flexible membrane 2. If Noise is not expected to radiate from the film to the outside, and a rigid cavity can be provided outside the film. At connection point 3, the vibration displacement of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com