Combined cigarette cartridge and production process thereof

A combined and pod technology, applied in the field of electronic cigarettes, can solve the problems of easy decomposition of natural flavors and affect the durability of the taste of natural flavors in electronic cigarettes, so as to reduce the heat absorption rate, reduce the possibility of thermal decomposition, and improve the durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation Example of Essence Microcapsules

[0041] The preparation examples of this application and the raw materials used in each preparation example can be obtained commercially, wherein the gelatin is selected from the industrial grade gelatin produced by Jinan Huijinchuan Chemical Co., Ltd., and the deionized water is selected from the product produced by Jinan Xinyuancheng Chemical Technology Co., Ltd. Deionized water, 325-mesh organic bentonite produced by Jinan Baoda Dyestuff Chemical Co., Ltd. was used for organic bentonite, natural jasmine essence sold by Jinan Yuncheng Biotechnology Co., Ltd. for jasmine fragrance selection, and Xi'an Musen Bioengineering Co., Ltd. for β-cyclodextrous selection. The food-grade β-cyclodextrin produced by the company, vinyl triethoxysilane is selected from Nanjing Ron Silicon Material Co., Ltd. Vinyl triethoxysilane KH-151, and the silica sol is selected from Shandong Leon New Material Technology Co., Ltd. The industrial-grad...

preparation example 1

[0043] In this preparation example, essence microcapsules are prepared according to the following method:

[0044] (1) Add 30kg of gelatin to 80kg of deionized water, and stir at 50°C until the gelatin dissolves to obtain a gelatin solution;

[0045] (2) 16kg of organic bentonite and 8kg of natural essence are added to the gelatin solution, and the capsule precursor liquid is obtained after stirring evenly, wherein the natural essence is selected with jasmine essence;

[0046] (3) The capsule precursor body fluid is freeze-dried, then pulverized, and passed through a 400-mesh sieve to obtain essence microcapsules.

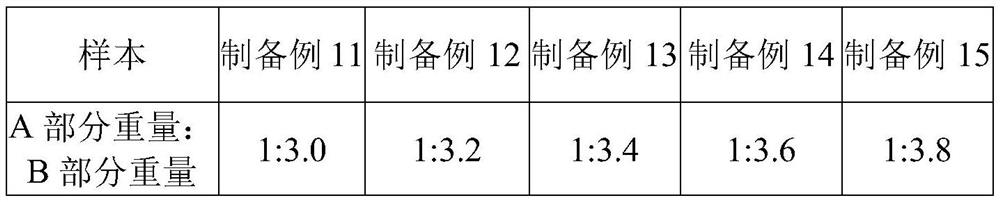

[0047] As shown in Table 1, the difference between Preparation Examples 1-5 is that the raw material proportions of the essence microcapsules are different.

[0048] Table 1

[0049] sample Organic bentonite / kg Natural essence / kg Gelatin / kg Deionized water / kg Preparation Example 1 16 8 30 80 Preparation example 2 18 9 35 90 ...

preparation example 6

[0051] The difference between this preparation example and preparation example 3 is that the formula of the essence microcapsules also includes 8 kg of stabilizer, and the stabilizer is selected from β-cyclodextrin, and the stabilizer is added to deionized water together with gelatin in step 1.

[0052] As shown in Table 2, the difference between Preparation Examples 6-10 is that the amount of stabilizer is different.

[0053] Table 2

[0054] sample Preparation Example 6 Preparation Example 7 Preparation example 8 Preparation Example 9 Preparation Example 10 Stabilizer / kg 8 9 10 11 12

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com