Woven bag processing cutting machine

A cutting machine and woven bag technology, which is applied in the field of woven bags, can solve the problems of woven bag surface and processing equipment obstruction, difficult cutting and processing of woven bags, and delay in processing time, so as to achieve high safety, avoid wrinkles, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

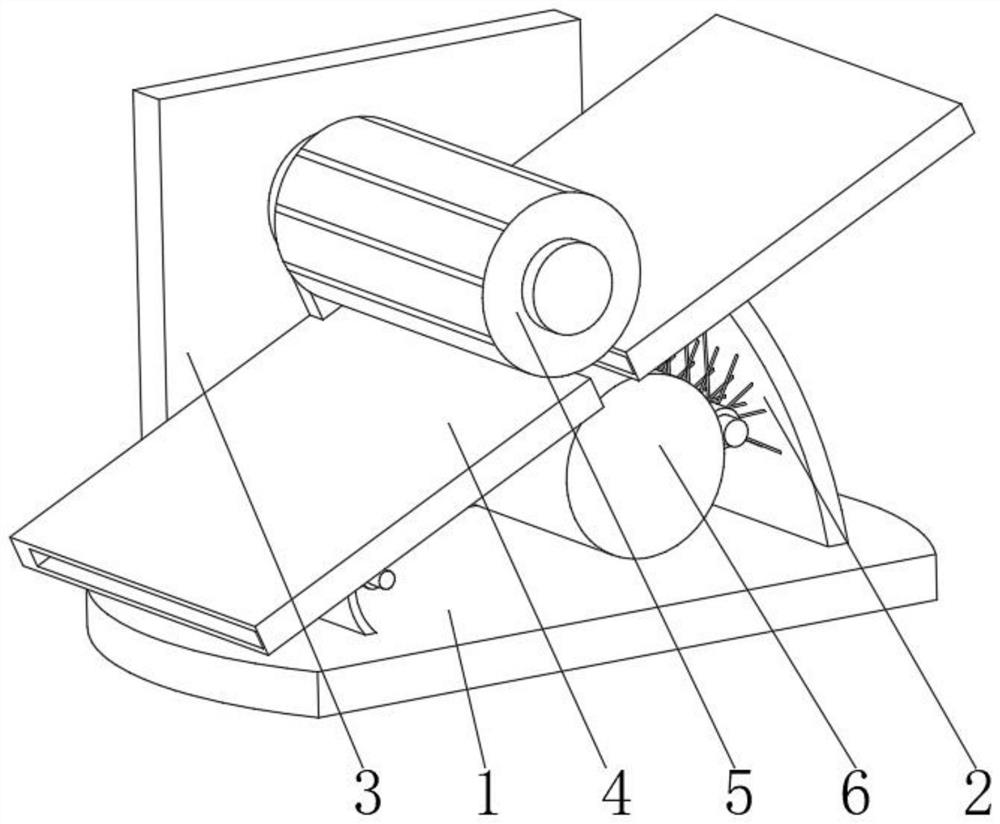

[0038] see Figure 1-2 , the present invention provides a technical solution: a woven bag processing and cutting machine, specifically comprising:

[0039] Base 1, the base 1 has a circular seat plate, and an angle adjustment device 2 installed in the middle of both sides of the top of the circular seat plate, and is fixed on the front and back of the top of the circular seat plate and is fixedly connected with a support frame 3;

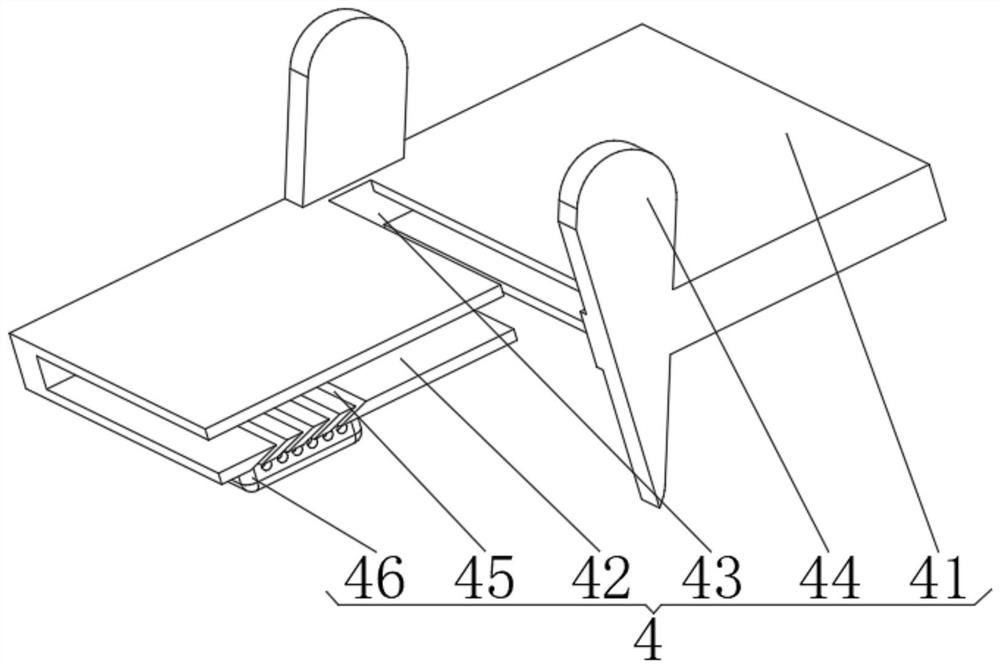

[0040]Cutting mechanism 4, this cutting mechanism 4 has a slat-shaped main body, and a cutter mechanism 5 installed in the middle position above the slat-shaped main body, and an auxiliary mechanism 6 installed in the middle position below the slat-shaped main body, through the slat-shaped The design of the cutting mechanism 4 is convenient for laying the woven bag, avoiding the wrinkling of the woven bag during the cutting process, and at the same time, the inclination angle of the cutting mechanism 4 is adjusted by the angle adjustment device 2, a...

Embodiment 2

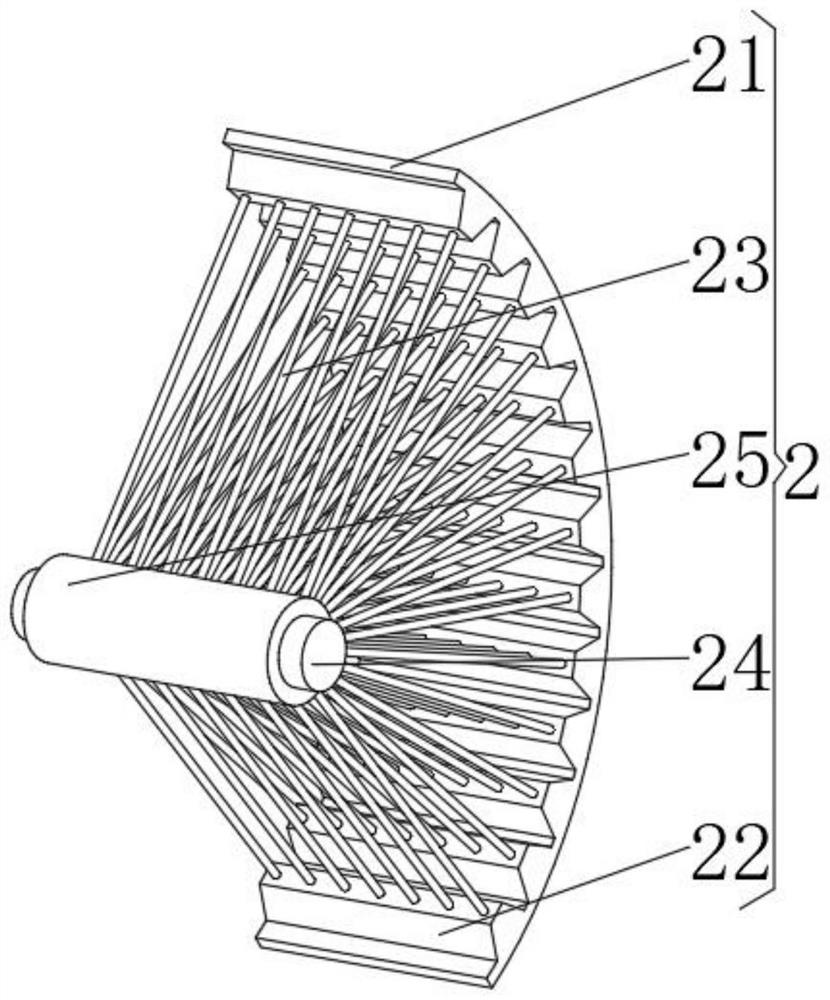

[0044] see Figure 1-3 , on the basis of Embodiment 1, the present invention provides a technical solution: the angle adjustment device 2 includes a support arc plate 21, and a limit protection block 22 installed on the concave surface of the support arc plate 21, and is fixed on the limit protection block 22 away from the support The traction rope 23 on one side of the arc plate 21 , the ratchet lock column 24 fixed on the other end of the traction rope 23 , and the lock cylinder 25 arranged on the outer surface of the ratchet lock column 24 . Through the length of the traction rope 23, the curvature of the supporting arc plate 21 is adjusted, and the impact force borne by the component itself is dispersively adjusted to realize the protection of the surrounding components. At the same time, the design of the limit protection block 22 can be mutually contacted and superimposed. Enhance the workpiece strength of the component itself and strengthen its self-protection ability. ...

Embodiment 3

[0048] see Figure 1-4 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the cutter mechanism 5 includes:

[0049] A cylinder 51, the cylinder 51 has a cylinder, and an access groove 52 on the surface of the cylinder, and an electromagnetic column 53 arranged in the middle of the cylinder cavity;

[0050] A cutting knife 54 , the cutting knife 54 has a cutting edge, positioning posts 55 installed on both sides of the cutting edge, and an arc-shaped support 56 fixed on the other end of the positioning post 55 . The positive current and reverse current of the external current can be used to control the magnetic attraction and repulsion of the electromagnetic column 53, and then control the cutting knife 54 to realize the cutting process. The control of the magnetic force avoids the direct contact of the components. Reduce the number of places where stress concentration occurs in the cutting knife 54, and prevent the cutting kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com