Matt silicone rubber for silk screen printing and preparation method thereof

A silicone rubber and matte technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of insufficient matte effect of matting powder, peeling off of silicone rubber silk screen layer, poor durability of matte effect, etc. , to achieve the effects of increasing the matte effect, improving the matte effect, and improving the matte effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

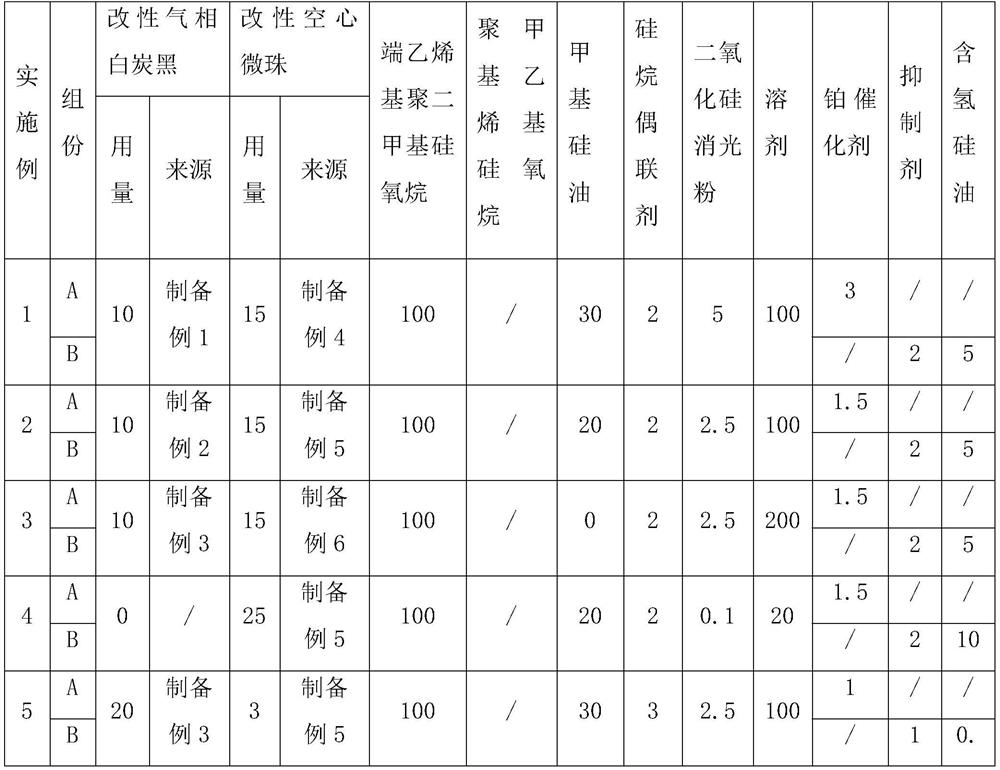

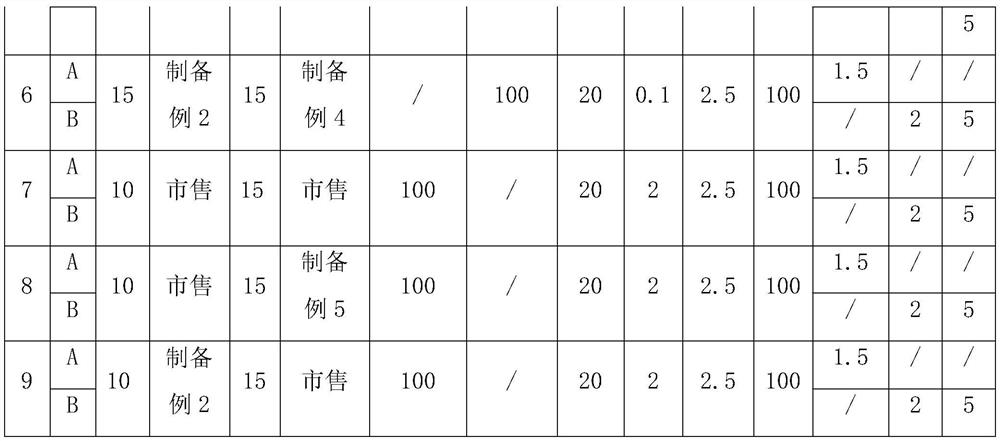

Examples

preparation example 1

[0074] A preparation of modified fumed silica, comprising the steps of:

[0075] S1: Weigh 60g of fumed silica, put it into an oven with a set temperature of 50°C, and dry it for 12 hours to obtain dry fumed silica for use; weigh 10g of hexamethyldisilazane and 120g of toluene, Put it into a three-necked flask with a reflux condenser installed in an oil bath heating jacket, stir it evenly by magnetic force to obtain the mixed solution A, and set aside;

[0076] S2: Add the dried fumed silica obtained in S1 into the mixed liquid A obtained in S1 three times, add 20g each time, mix well and then add another 20g until 60g is completely added, and heat to 80°C , stirring and reacting at constant temperature for 5 hours to prepare a mixed solution B for subsequent use;

[0077] S3: Weigh 5g of octamethylcyclotetrasiloxane and add it to the mixed solution B obtained in S2, mix evenly, heat up to 120°C, stir and react at a constant temperature for 3h, cool to room temperature, filte...

preparation example 2

[0079] A preparation of modified fumed silica, comprising the steps of:

[0080] S1: Weigh 55g of fumed silica, put it in an oven with a set temperature of 50°C, bake for 8 hours to obtain dry fumed silica, and set aside; weigh 8g of hexamethyldisilazane and 100g of toluene, put In a three-necked flask with a reflux condenser, heat the magnetic stirrer through an oil bath and mix evenly to obtain a mixed solution A, which is set aside;

[0081] S2: Add the dried fumed silica obtained in S1 to the mixed liquid A obtained in S1 in three times, add 20g for the first time, mix evenly, then add another 20g, finally add 15g, mix evenly, heat to 90 ℃, stirring at constant temperature for 3 hours to prepare the mixed solution B and set aside;

[0082] S3: Weigh 3g of octamethylcyclotetrasiloxane and add it to the mixed solution B prepared in S2, mix well, heat up to 115°C, stir at constant temperature for 2h, cool to room temperature, and filter with a vacuum filter , placed in an o...

preparation example 3

[0084] A preparation of modified fumed silica, comprising the steps of:

[0085] S1: Weigh 50g of fumed silica, put it into an oven with a set temperature of 50°C, and dry it for 6h to obtain dry fumed silica for use; weigh 5g of hexamethyldisilazane and 80g of toluene, Put it into a three-necked flask with a reflux condenser installed in an oil bath heating jacket, stir it evenly by magnetic force to obtain the mixed solution A, and set aside;

[0086] S2: Add the dried fumed silica obtained in S1 into the mixed liquid A obtained in S1 three times, add 20g for the first time and mix evenly, then add another 20g, finally add 10g and mix evenly, heat to 100°C , stirring and reacting at constant temperature for 1 h to prepare the mixed solution B for subsequent use;

[0087] S3: Weigh 1g of octamethylcyclotetrasiloxane and add it to the prepared mixed solution B in S2, mix well, heat up to 110°C, stir at constant temperature for 1h, cool to room temperature, and filter with a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com