Method for determining related impurities I of atorvastatin calcium

A technology of atorvastatin calcium and related impurities, which is applied in the detection field of pharmaceutical impurities to achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

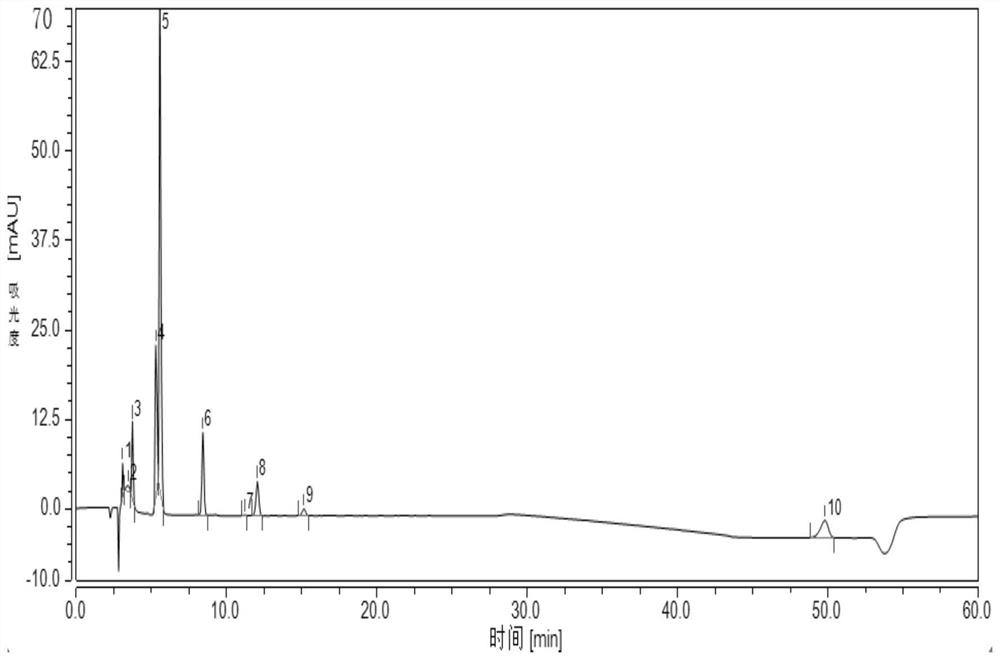

Embodiment 1

[0031] 1. HPLC chromatographic conditions Chromatographic column: Wondasil C18 (4.6mm×250mm, 5μm);

[0032] Mobile phase: mobile phase A is acetonitrile-tetrahydrofuran-acetate buffer, wherein the volume ratio of acetonitrile: tetrahydrofuran: acetate buffer is 35:3:62;

[0033] Mobile phase B is acetonitrile-tetrahydrofuran-acetate buffer, wherein the volume ratio of acetonitrile: tetrahydrofuran: acetate buffer is 82:3:15;

[0034] The preparation method of the acetic acid buffer solution is: take 1.50g of ammonium acetate, add 700mL of water to dissolve, after dissolving, adjust the pH to 4.0 with glacial acetic acid, then add water to 1000mL;

[0035] Flow rate: 1.0ml / min;

[0036] Detection wavelength: 244nm, column temperature 30°C;

[0037] Injection volume: 20μL;

[0038] The mobile phase gradient elution conditions are shown in Table 1.1.

[0039] Table 1.1 Mobile phase gradient elution conditions

[0040] time / min Mobile phase A / % Mobile phase B / % ...

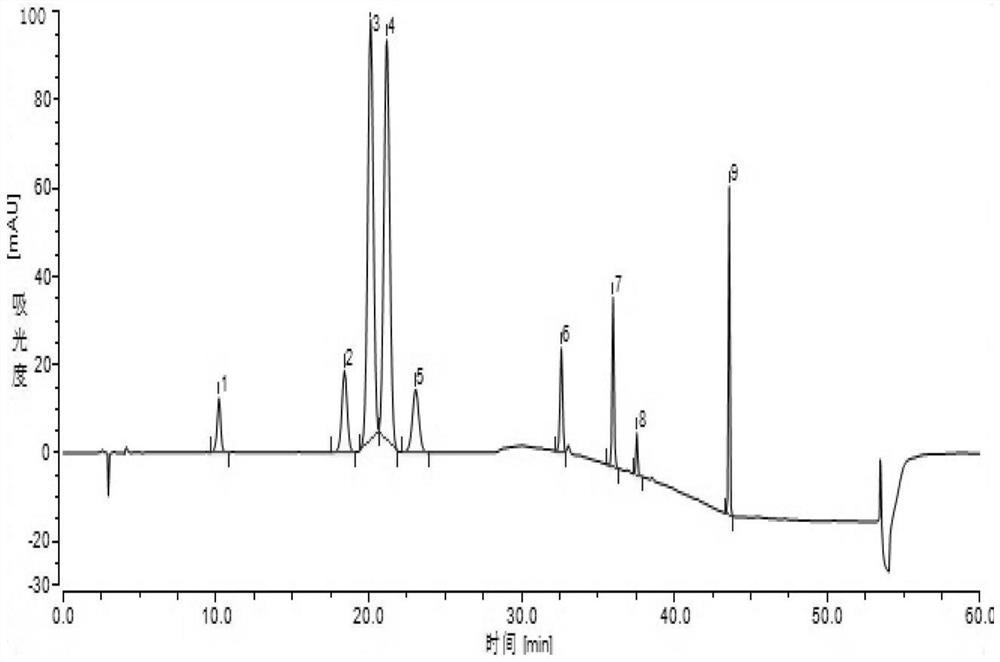

Embodiment 2

[0052] 1. HPLC chromatographic conditions Chromatographic column: Wondasil C18 (4.6mm×250mm, 5μm);

[0053] Mobile phase: mobile phase A is acetonitrile-tetrahydrofuran-acetate buffer, wherein the volume ratio of acetonitrile: tetrahydrofuran: acetate buffer is 40:5:55;

[0054] Mobile phase B is acetonitrile-tetrahydrofuran-acetate buffer, wherein the volume ratio of acetonitrile: tetrahydrofuran: acetate buffer is 85:5:10;

[0055] The preparation method of the acetic acid buffer solution is: take 1.55g of ammonium acetate, add 800mL of water to dissolve, after dissolving, adjust the pH to 4.0 with glacial acetic acid, then add water to 1000mL;

[0056] Flow rate: 1.0ml / min;

[0057] Detection wavelength: 244nm, column temperature 30°C;

[0058] Injection volume: 20μL;

[0059] The mobile phase gradient elution conditions are shown in Table 2.1.

[0060] Table 2.1 Mobile phase gradient elution conditions

[0061] time / min Mobile phase A / % Mobile phase B / % ...

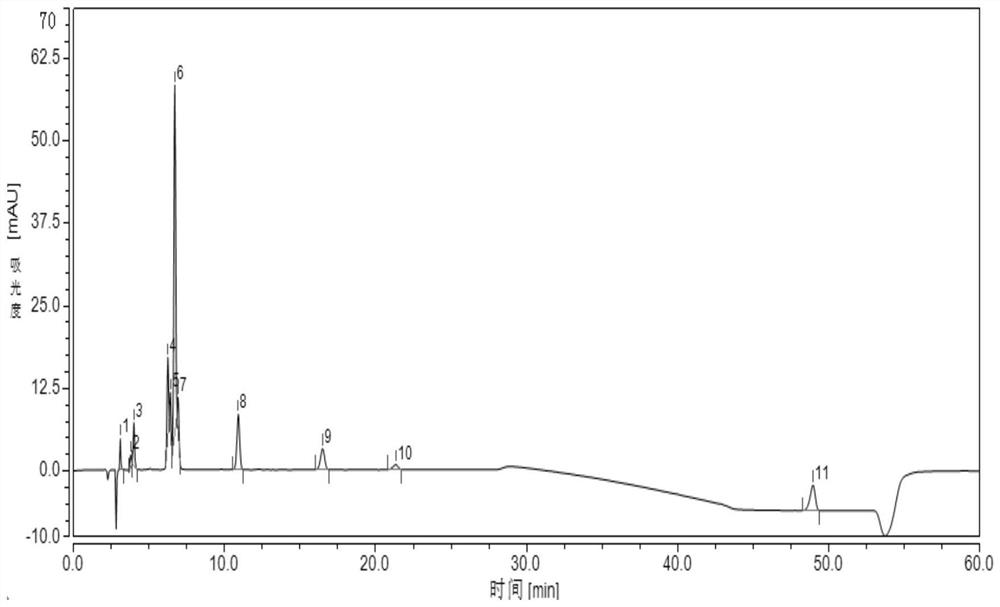

Embodiment 3

[0096] 1. HPLC chromatographic conditions Chromatographic column: Wondasil C18 (4.6mm×250mm, 5μm);

[0097] Mobile phase: mobile phase A is acetonitrile-tetrahydrofuran-acetate buffer, wherein the volume ratio of acetonitrile: tetrahydrofuran: acetate buffer is 45:7:48;

[0098] Mobile phase B is acetonitrile-tetrahydrofuran-acetate buffer solution, wherein the volume ratio of acetonitrile: tetrahydrofuran: acetate buffer solution is 87:7:6; the preparation method of acetate buffer solution is: take 1.58g ammonium acetate, add 900mL water for Dissolve, after dissolving, adjust the pH to 4.0 with glacial acetic acid, then add water to 1000mL;

[0099] Flow rate: 1.0ml / min;

[0100] Detection wavelength: 244nm, column temperature 30°C;

[0101] Injection volume: 20μL;

[0102] The mobile phase gradient elution conditions are shown in Table 3.1.

[0103] Table 3.1 Mobile phase gradient elution conditions

[0104] time / min Mobile phase A / % Mobile phase B / % 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com