Vibration plate and sound production device

A technology of sound-generating device and vibrating plate, which is applied in the direction of fiber diaphragm, flat diaphragm, polymer material diaphragm, etc., can solve the problems of abnormal sound of the sound-generating device, easy dehydration and brittleness of the paper cone, and heating of the voice coil, so as to achieve accurate sound production. , low distortion, suitable damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

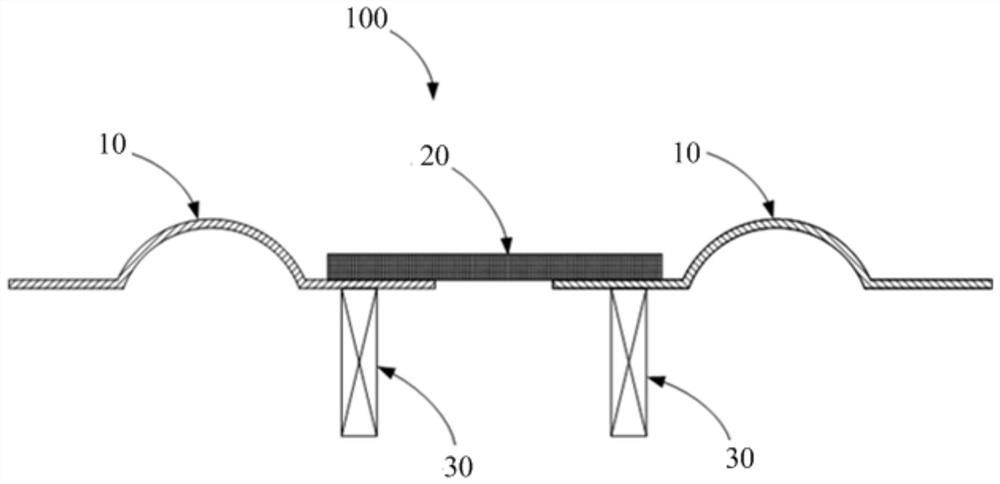

[0064] It should be noted that the vibrating plate of the present invention can be prepared by the following steps:

[0065] First, polyetherimide fibers and carbon fibers are dispersed in a solvent, mixed evenly, and the solvent is removed to obtain a composite fiber material. Wherein, the mass ratio of the polyetherimide fiber to the carbon fiber ranges from 100:5 to 100:90. Here the solvent can be water or an organic solvent, and the organic solvent can be one of methanol, ethanol, isopropanol, acetone, methyl ethyl ketone, ethyl acetate, butyl acetate, n-hexane, cyclohexane, sherwood oil, toluene or Various mixes.

[0066] Secondly, the composite fiber material is placed in a mold and compressed according to a predetermined compression ratio to prepare a composite fiber layer with a predetermined density.

[0067] It should be noted that, in order to enhance the bonding force between the carbon fiber and the polyetherimide fiber in the composite fiber, a bonding fiber is...

Embodiment 1

[0074] The vibrating plate of this embodiment is prepared by the following steps:

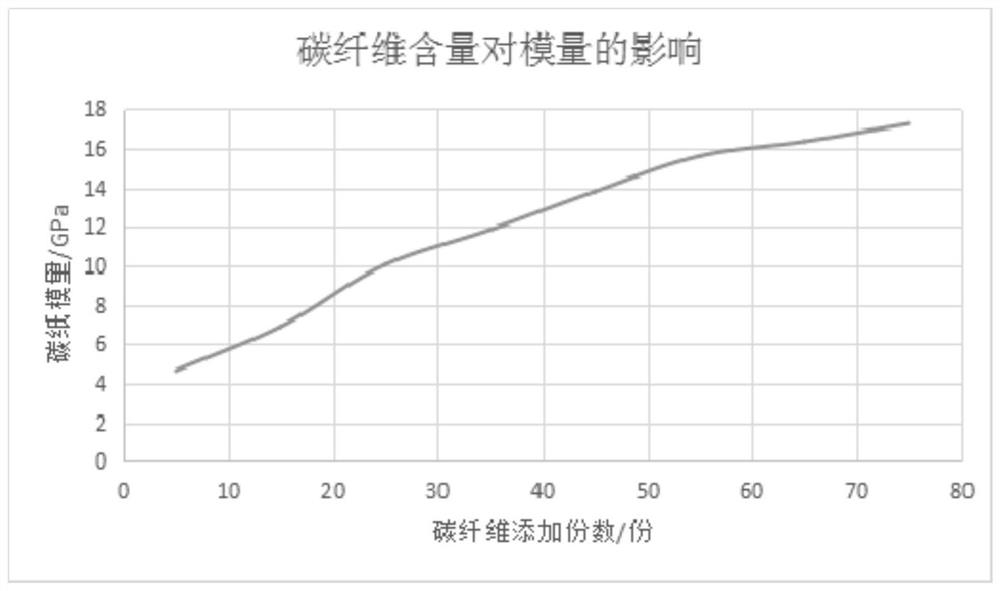

[0075] 1. In terms of mass, weigh 100 parts of polyetherimide fibers with a diameter of 10 μm, cut them into short fibers with a length of 20mm-40mm, and disperse them in 400 parts of ethanol solvent, and stir to make them evenly dispersed.

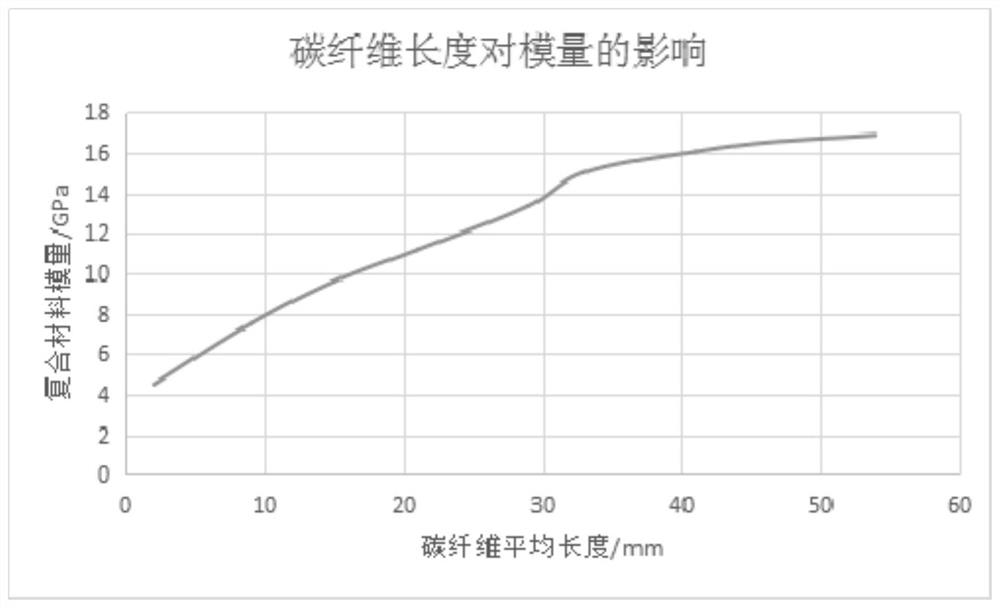

[0076] 2. Weigh 40 parts of carbon fibers with a diameter of 7 μm, cut them into short fibers with an average length of 20 mm, add them to the above-mentioned ethanol solvent, and continue to stir so that the two fibers are evenly dispersed in the ethanol solvent.

[0077] 3. Remove the two kinds of fibers from the ethanol solvent together, and dry and remove the ethanol solvent to obtain a composite fiber material uniformly composited between carbon fiber and polyetherimide fiber, and the composite fiber material has a three-dimensional network structure.

[0078] 4. Put the composite fiber material in the mold and compress it according to a predetermined...

Embodiment 2

[0081] The carbon fibers in Example 1 were treated with a coupling agent, and other steps were the same as those in Example 1.

[0082] The specific steps of carbon fiber treated by coupling agent are as follows:

[0083] First, take 10 parts of the coupling agent and add it into a blended solvent of 100 parts of water and 900 parts of ethanol, and fully stir to obtain a pretreatment agent.

[0084] Then take 40 parts of carbon fibers with a diameter of 7 μm, cut them into short fibers with an average length of 20 mm, add them to the above pretreatment agent, stir them thoroughly, and let them stand for 4 hours.

[0085] Then the treated carbon fibers are filtered out and dried to obtain surface-treated carbon fibers.

[0086] It should be noted that the coupling agent here can be selected from one of KH-540, KH-550, KH-560, KH-570, KH-590, KH-792, Si-602, Si-563, and A-151 or more. Moreover, based on 100 parts by mass of the blended solvent, the amount of the coupling agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap