High-temperature flue gas desulfurizer and preparation method thereof

A high-temperature flue gas and desulfurization agent technology, applied in the field of gas purification, to achieve the effects of inhibiting grain sintering and structural collapse, rich active sites, and uniform distribution of oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

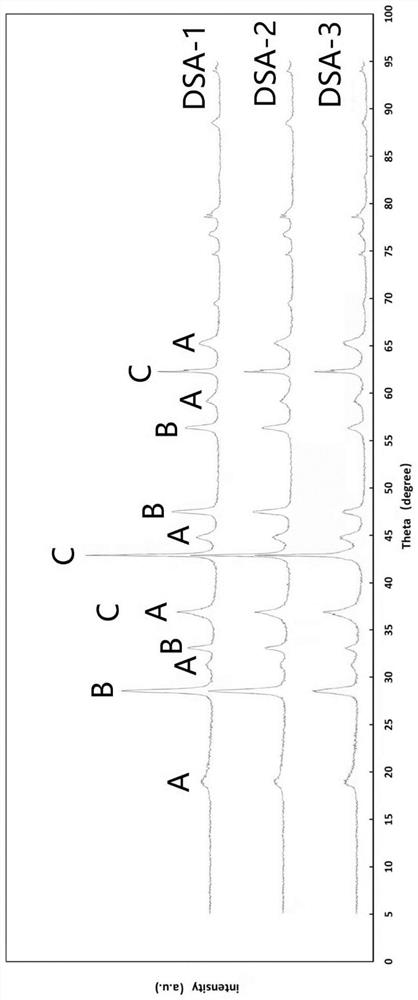

Image

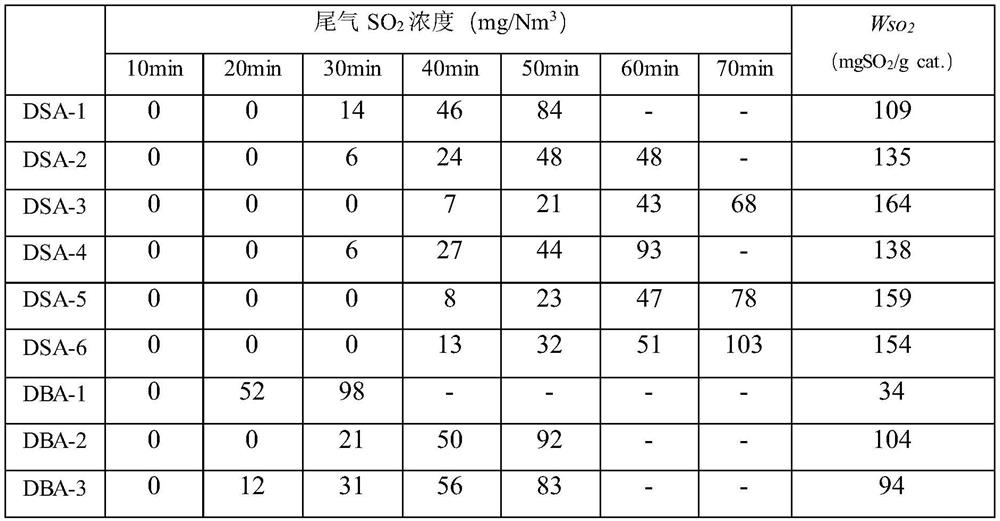

Examples

preparation example Construction

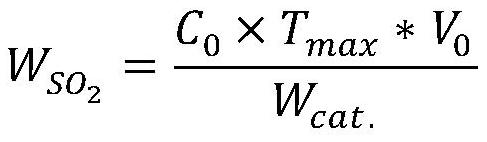

[0017] Some embodiments of the present invention provide a method for preparing a high-temperature flue gas desulfurizer, which includes: using a divalent metal ion salt and a water-soluble aluminum salt as raw materials, sequentially adopting a co-precipitation method and a hydrothermal crystallization method to prepare a A layered double metal hydroxide precursor with an aluminum hydrotalcite structure, and then the salt solution of the catalytically active component is embedded into the layered double metal hydroxide precursor through an exchange reaction to obtain the first slurry, and the first The slurry is molded and then roasted to obtain a high-temperature flue gas desulfurizer.

[0018] The inventors found that there are multiple valence states of sulfur in high-temperature flue gas SOx, and low-valence sulfur in flue gas, such as SO 2 , its reaction efficiency and product stability with basic oxides under high temperature conditions are insufficient, so it cannot be...

Embodiment 1

[0051] This embodiment provides a kind of preparation method of desulfurizer, and its concrete steps comprise:

[0052] (1) Preparation of layered magnesium aluminum double hydroxide precursor:

[0053] 230.8g of Mg(NO 3 ) 2 ·6H 2 O and 168.8g of Al(NO 3 ) 3 9H 2 O was dissolved in 750g deionized water to prepare a mixed salt solution, 145.8g NaOH was dissolved in 750g deionized water to prepare a lye, and 500g deionized water was added to a 3L beaker, and under rapid stirring conditions, the mixed salt solution was mixed with alkali The solution was slowly added into the beaker at the same speed, and after the dropwise addition was completed, the stirring was continued for a period of time to fully react the materials, and then transferred to a hydrothermal kettle for crystallization and aging at 90°C for 16 hours, and then the precipitate was separated by filtration and taken. The filter cake was washed with deionized water until neutral, dried and ground to obtain abo...

Embodiment 2

[0059] This embodiment provides a kind of preparation method of desulfurizer, and its concrete steps comprise:

[0060] (1) Preparation of layered magnesium aluminum double hydroxide precursor:

[0061] 230.8g of Mg(NO 3 ) 2 ·6H 2 O and 168.8g of Al(NO 3 ) 3 9H 2 O was dissolved in 750g deionized water to prepare a mixed salt solution, 145.8g NaOH was dissolved in 750g deionized water to prepare a lye, and 500g deionized water was added to a 3L beaker, and under rapid stirring conditions, the mixed salt solution was mixed with alkali The solution was slowly added into the beaker at the same speed, and after the dropwise addition was completed, continue to stir for a period of time to fully react the materials, then transfer to a hydrothermal kettle, crystallize and age for 14 hours at 100°C, then filter and separate the precipitate, and use Wash with deionized water until neutral, dry and grind to obtain about 87g layered magnesium aluminum double hydroxide precursor.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com