Evaporator with double-sided arched flexible carbon film and preparation method thereof

An evaporator, arched technology, applied in the field of evaporator with double-sided arched flexible carbon film and its preparation, to achieve high evaporation rate, strong capillary action, and solve energy problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing an evaporator with a double-sided arched flexible carbon film. The specific steps are as follows:

[0030] 1. Preparation of Double-sided Arched Flexible Carbon Membrane

[0031] (1) First cut the carbon cloth into the desired size (for example, 2*3cm), and then wash it with acetone, ethanol solution and deionized water for 10 minutes to clean the carbon cloth.

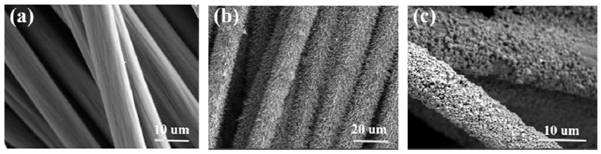

[0032] (2) After drying in air, put the carbon cloth into the magnetron sputtering system (560C). With a DC power supply as the sputtering source, the vacuum degree of the sputtering chamber was pumped to 9.0×10-4Pa through a mechanical pump and a molecular pump in turn, and then argon gas (100sccm) was introduced, and the pressure in the vacuum chamber was adjusted to 0.6Pa . The sputtering process uses a high-purity copper target (99.9%), and pre-sputters for 15 minutes before sputtering to remove oxides on the copper surface. Afterwards, sputtering was perform...

Embodiment 1

[0039] 1. Preparation of Double-sided Arched Flexible Carbon Membrane

[0040](1) First cut the carbon cloth into the required size (2*3cm), and then wash it with acetone, ethanol solution and deionized water for 10 minutes to clean the carbon cloth.

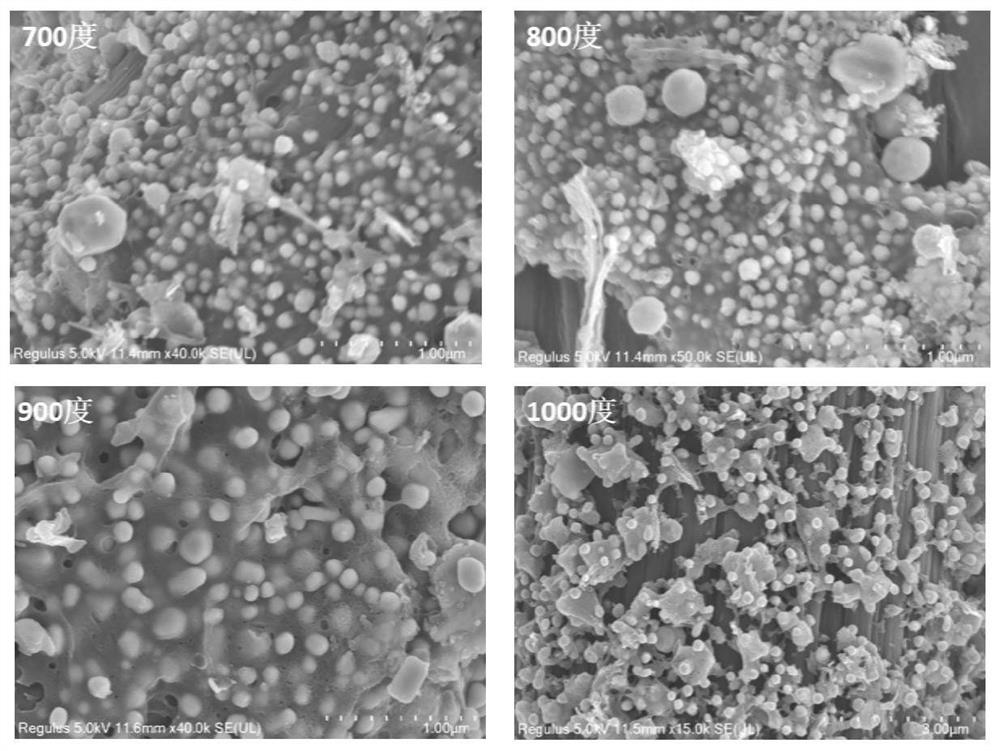

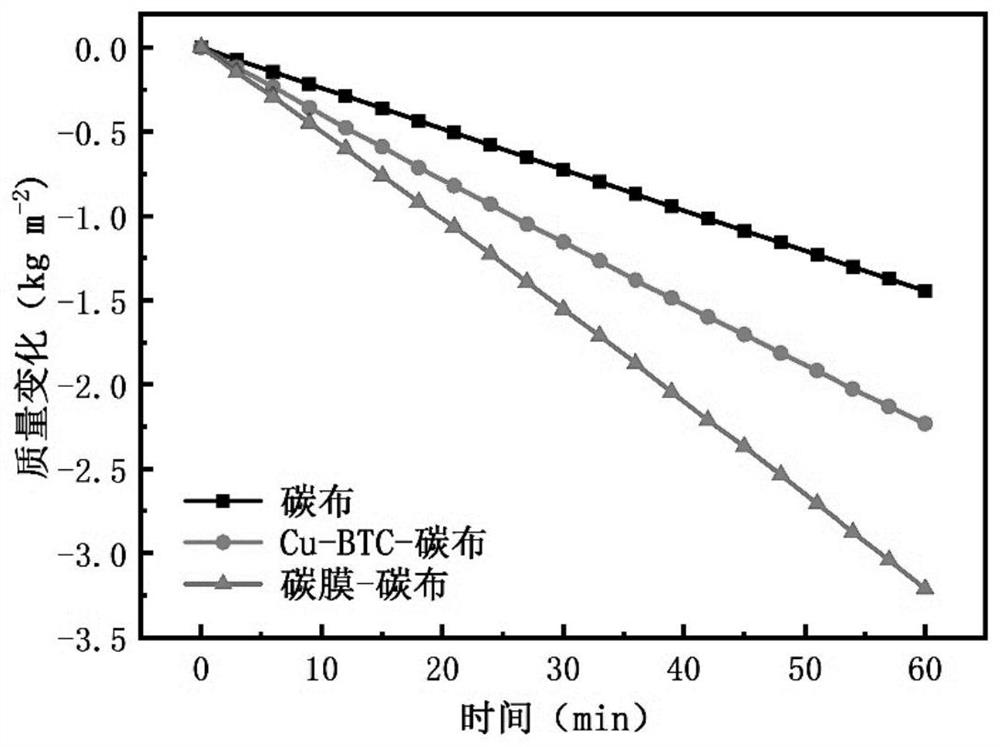

[0041] (2) After drying in air, put the carbon cloth into the magnetron sputtering system (560C). With a DC power supply as the sputtering source, the vacuum degree of the sputtering chamber was pumped to 9.0×10-4Pa through a mechanical pump and a molecular pump in turn, and then argon gas (100sccm) was introduced, and the pressure in the vacuum chamber was adjusted to 0.6Pa . The sputtering process uses a high-purity copper target (99.9%), and pre-sputters for 15 minutes before sputtering to remove oxides on the copper surface. Afterwards, sputtering was performed for 30 min under the condition that the flow rate of argon gas was 0.5 and the power was 65 W, so that the sputtered copper was uniformly deposited on the carbon fi...

Embodiment 2

[0048] 1. Preparation of double-sided arched flexible carbon film (1) First cut the carbon cloth into the required size (2*3cm), and then wash it with acetone, ethanol solution and deionized water for 10 minutes to clean the carbon cloth.

[0049] (2) After drying in air, put the carbon cloth into the magnetron sputtering system (560C). With a DC power supply as the sputtering source, the vacuum degree of the sputtering chamber was pumped to 9.0×10-4Pa through a mechanical pump and a molecular pump in turn, and then argon gas (100sccm) was introduced, and the pressure in the vacuum chamber was adjusted to 0.6Pa . The sputtering process uses a high-purity copper target (99.9%), and pre-sputters for 15 minutes before sputtering to remove oxides on the copper surface. Afterwards, sputtering was performed for 30 min under the condition of an argon gas flow rate of 100 Å and a power of 70 W, so that the sputtered copper was uniformly deposited on the carbon fibers. Then change th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com