Synthesis method of solid chelating agent piperazine-N, N-sodium bis-dithiocarbamate

A technology of sodium bis-dithiocarbamate and a synthesis method, applied in the directions of organic chemistry, organic chemistry, etc., can solve the problems of inconvenient transportation and storage of liquid products, difficult preparation of solid products, and unsatisfactory product yields, and avoid the problems of Problems in storage and transportation, shortening of dripping time, effect of less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The synthesis method of a solid chelating agent piperazine-N, N-bistetiocarbamine provided by the present invention includes the following steps:

[0040] Step S1, the secondary amine negative ionization stage of piperazine:

[0041] Anhydrous piperazine, tetramethylolide is added to water, stirred, then dissolved, then add a sodium hydroxide solution to heating the reaction for a period of time to obtain a solution A;

[0042] Step S2, the secondary amine negative ion and the dioxide double nucleophilic reaction stage:

[0043] Diulfide is added dropwise to the solution A obtained in step S1, the temperature is maintained and reacted to give a solution of sodium piperazine-N, N-Di diimethylhydrine.

[0044] Step S3, the crystallization stage:

[0045] The piperazine-N, N-double diimethylmethoamate solution obtained in step S2, carried out, solid-liquid separation, washing, drying, pulverine-N, N-bis diiminogenate crystalline solid;

[0046] Step S4, the secondary crystalli...

Embodiment 1

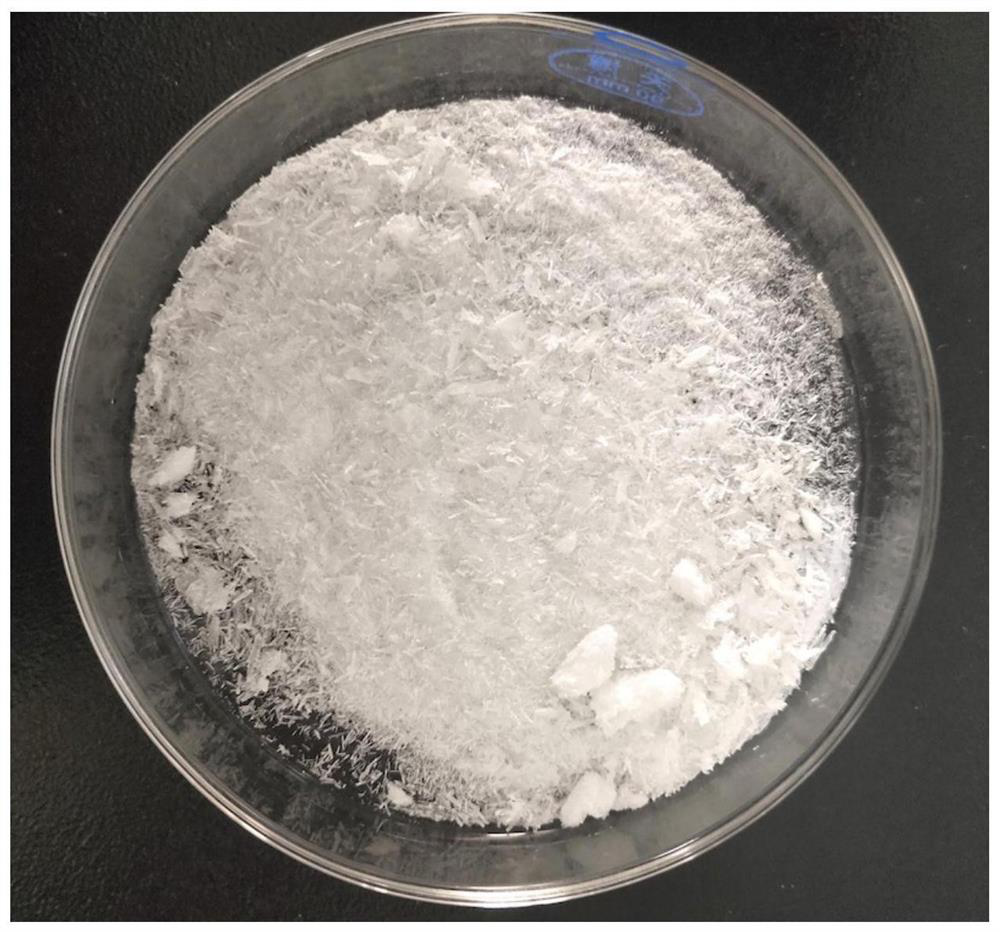

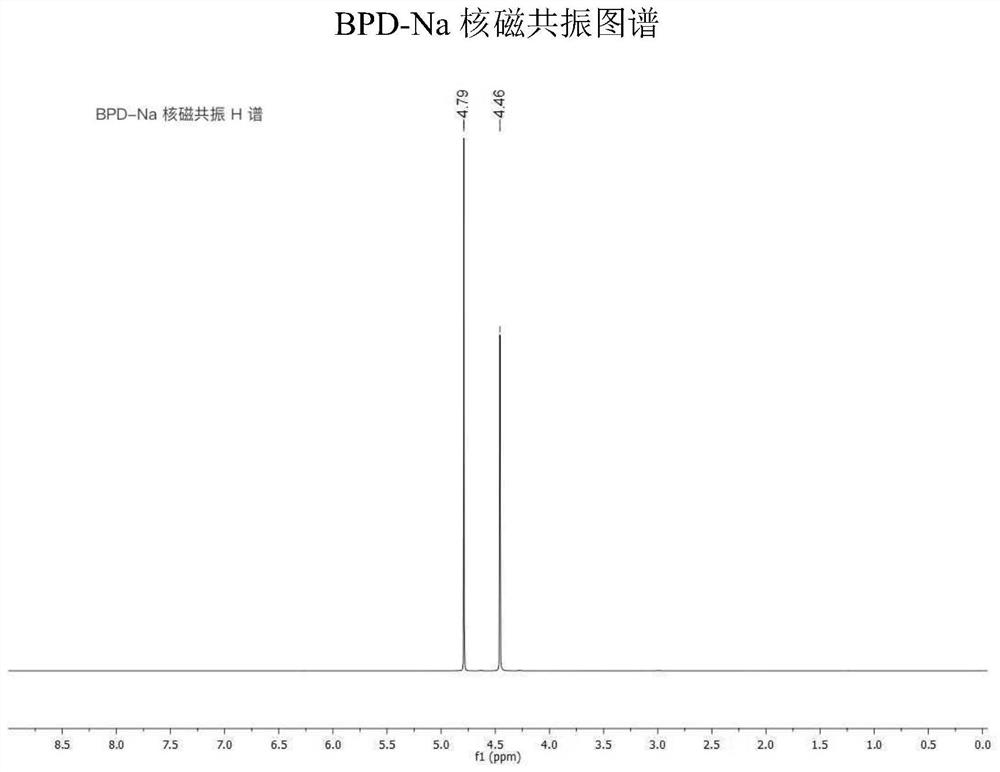

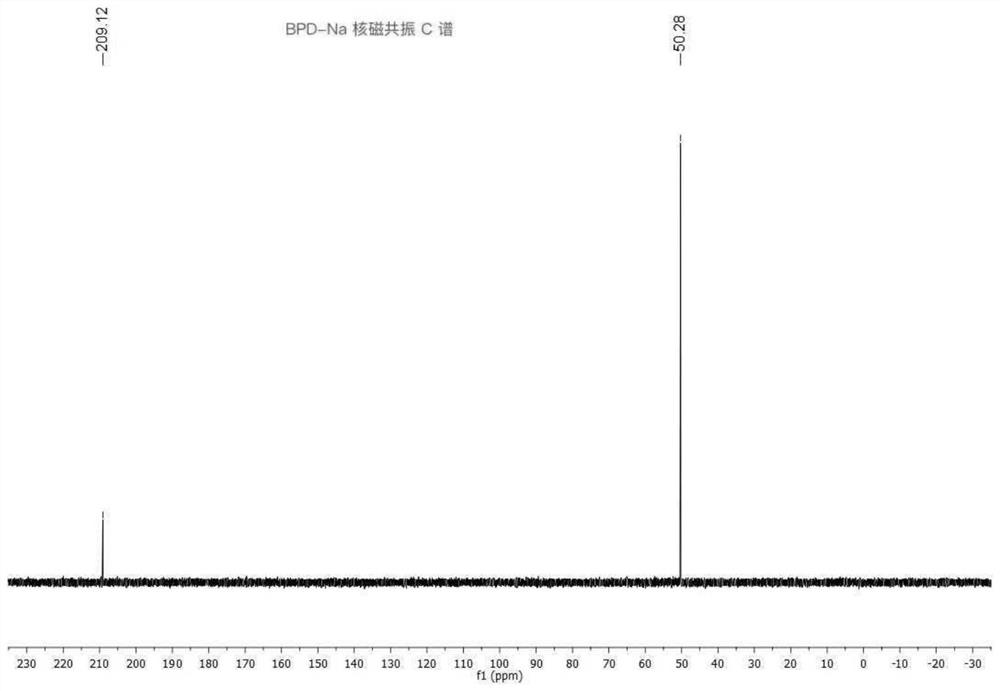

[0059] 157.5 g of deionized water was added to 500 ml of four-mouth flasks equipped with a thermometer, dropping funnel, and 49.5 g of anhydrous piperazine, 0.32 g of tetramethylguanidine, stirred; stir for 15-20 minutes, stay After all piperazine dissolve, 112.5 g of 40% sodium hydroxide solution was added to the four flasks, and stirring was continued for 10 minutes; after using a water bath to lower the solution temperature to below 30 ° C, start dripping from the drip drain into the four flasks Add 89.1 g of carbon sulfide, the dropwise time is 10-15 minutes, the temperature of the dripping process is maintained below 30 ° C; the carbon disulfide is added, heated to heat the temperature to the solution temperature of 42 ° C, withdraw the water bath, continue to continue The reaction was stirred for 10 minutes. After the reaction is completed, the solution is reduced to room temperature to obtain a solid product, washed, separated, dried, and powdered to obtain a white crystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com