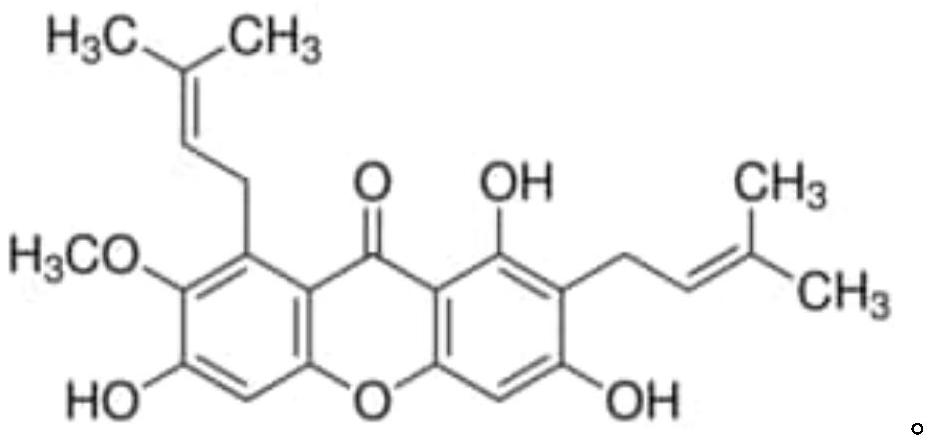

Method for extracting alpha-mangostin and gamma-mangostin from mangosteen

A technology of mangostin and mangostin, which is applied in the field of extracting α-mangostin and γ-mangostin from mangosteen, can solve the problems of unfavorable industrial production, insufficient utilization of raw materials, numerous process steps, etc., and achieve low cost, High safety and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

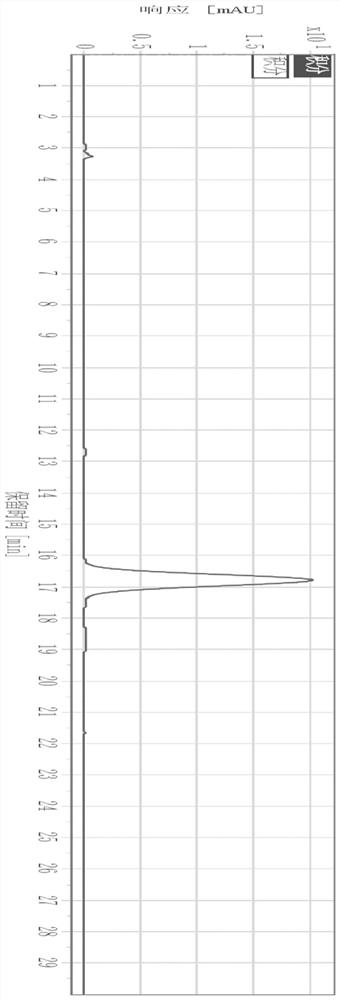

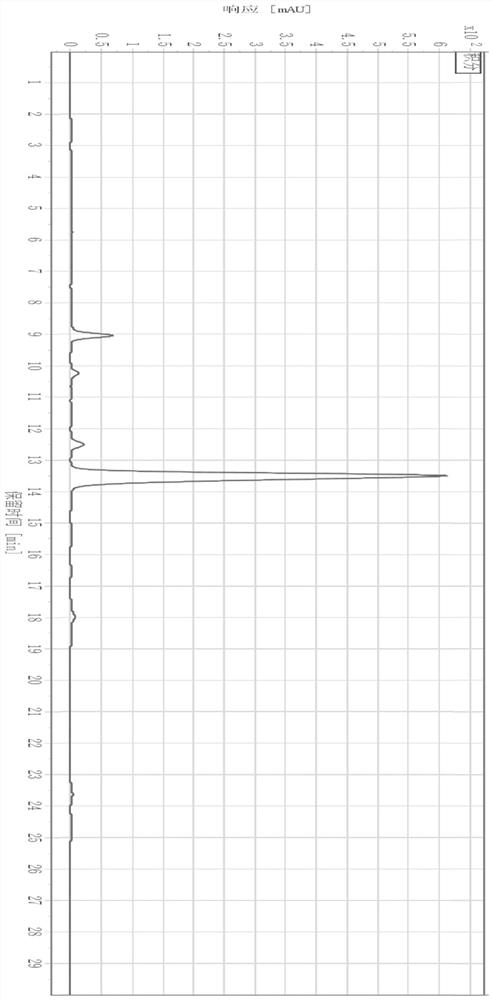

Image

Examples

Embodiment 1

[0085] The present embodiment is a kind of extracting method of mangosteen bark, comprising the following steps:

[0086] S1. Grind 500 g of mangosteen bark raw material, heat and reflux extract with 10 times volume fraction of 70% ethanol aqueous solution, extract twice, extraction time 2h / time, to obtain extract.

[0087] S2. Concentrate the extract until there is no alcohol smell, separate the solid and liquid, collect the precipitate, add 5 times the volume fraction of 40% ethanol solution to the precipitate to fully dissolve, filter, and use the filtrate for later use.

[0088] S3, the filtrate was purified using HPD400 macroporous resin, and eluted with 1BV water, 3BV volume fraction of 40% ethanol aqueous solution, and 3BV volume fraction of 70% ethanol aqueous solution, and the elution flow rate was 1BV / h; the collection volume fraction was 70 % ethanol solution in water.

[0089] S4. Add 1‰ diatomaceous earth (mass fraction) to the eluent with a volume fraction of 70...

Embodiment 2

[0094] The present embodiment is a kind of extracting method of mangosteen bark, comprising the following steps:

[0095] S1. Grind 500 g of mangosteen bark raw material, heat and reflux extract twice with 10 times volume fraction of 90% ethanol aqueous solution, extraction time is 1 h / time, separate solid and liquid, and collect extract.

[0096] S2. Concentrate the extract under reduced pressure until there is no alcohol smell, separate the solid from the liquid, collect the precipitate, add 10 times the volume fraction of 50% ethanol solution to the precipitate to fully dissolve, filter, and use the filtrate for later use.

[0097] S3. Purify the filtrate in step S2 with LSA-12 resin, and use 2BV of water, 2BV of 50% ethanol aqueous solution, and 3BV of 80% ethanol aqueous solution for elution, and the elution flow rate is 1.5BV / h. The eluate with a volume fraction of 80% ethanol in water was collected.

[0098] S4. Add 5‰ activated carbon (mass fraction) to the eluent wit...

Embodiment 3

[0103] The present embodiment is a kind of extracting method of mangosteen bark, comprising the following steps:

[0104] S1. Grinding 500 g of mangosteen bark raw material, extracting with 10 times the volume fraction of 80% ethanol aqueous solution, extraction temperature is 90° C., extraction 3 times, extraction time 1 h / time, to obtain extract.

[0105] S2. Concentrate the extract until there is no alcohol smell, separate the solid and liquid, collect the precipitate, add 20 times the volume fraction of 40% ethanol solution to the precipitate to fully dissolve, filter, and use the filtrate for later use.

[0106] S3. Purify the filtrate in step S2 with LX-38 resin, use 3BV of water, 1BV of 40% ethanol aqueous solution, and 4BV of 70% ethanol aqueous solution to elute, and the elution flow rate is 2BV / h, collect The volume fraction is the eluent of 70% ethanol aqueous solution.

[0107] S4. Add 3‰ activated carbon (mass fraction) to the eluent with a volume fraction of 70%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com