Rubber sealing film for coal tar gas and preparation method

A technology of rubber sealing and tar gas, applied in the direction of chemical instruments and methods, applications, household appliances, etc., can solve the problems of poor ozone resistance and weather resistance, achieve advanced equipment, ensure strength requirements, and reduce the number of bonding seams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

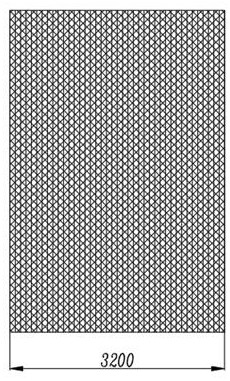

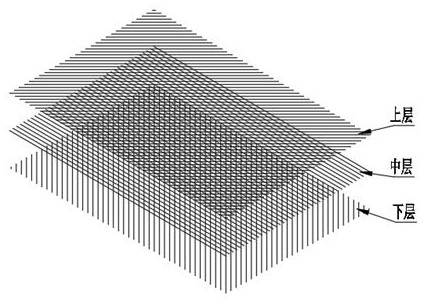

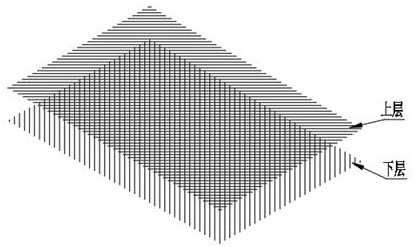

Image

Examples

Embodiment 1

[0044] A rubber sealing film for coal tar gas, comprising the following raw materials in parts by weight:

[0045] 100 parts of nitrile rubber, 31 parts of polyvinyl chloride, 3 parts of vulcanizing agent, 16 parts of carbon black, 6 parts of paraffin, 2 parts of anti-aging agent, 3 parts of accelerator, and 6 parts of plasticizer. The accelerator is rubber accelerator DM. The anti-aging agent of the rubber sealing film for coal tar gas is anti-aging agent 4010NA.

[0046] The preparation method of described coal tar gas rubber seal film, comprises the steps:

[0047]S1. Pre-swelling of polyvinyl chloride: Before blending polyvinyl chloride and nitrile rubber, plasticizing and swelling treatment is required. This process is completed on a high-speed kneader.

[0048] S2. The blending of polyvinyl chloride, nitrile rubber, carbon black, paraffin, anti-aging agent, accelerator and plasticizer is carried out on the internal mixer. 168℃~175℃,

[0049] S3. Cord cloth gluing, th...

Embodiment 2

[0056] A rubber sealing film for coal tar gas, comprising the following raw materials in parts by weight:

[0057] 100 parts of nitrile rubber, 31 parts of polyvinyl chloride, 3 parts of vulcanizing agent, 16 parts of carbon black, 6 parts of paraffin, 2 parts of anti-aging agent, 3 parts of accelerator, and 6 parts of plasticizer. The accelerator is rubber accelerator DM. The anti-aging agent of the rubber sealing film for coal tar gas is anti-aging agent 4010NA.

[0058] The preparation method of described coal tar gas rubber seal film, comprises the steps:

[0059] S1. Pre-swelling of polyvinyl chloride: Before blending polyvinyl chloride and nitrile rubber, plasticizing and swelling treatment is required. This process is completed on a high-speed kneader.

[0060] S2. The blending of polyvinyl chloride, nitrile rubber, carbon black, paraffin, anti-aging agent, accelerator and plasticizer is carried out on the internal mixer. 168℃~175℃,

[0061] S3. Cord cloth gluing, t...

Embodiment 3

[0067] A rubber sealing film for coal tar gas, comprising the following raw materials in parts by weight:

[0068] 100 parts of nitrile rubber, 31 parts of polyvinyl chloride, 3 parts of vulcanizing agent, 16 parts of carbon black, 6 parts of paraffin, 2 parts of anti-aging agent, 3 parts of accelerator, and 6 parts of plasticizer. The accelerator is rubber accelerator DM. The anti-aging agent of the rubber sealing film for coal tar gas is anti-aging agent 4010NA.

[0069] The preparation method of described coal tar gas rubber seal film, comprises the steps:

[0070] S1. Pre-swelling of polyvinyl chloride: Before blending polyvinyl chloride and nitrile rubber, plasticizing and swelling treatment is required. This process is completed on a high-speed kneader.

[0071] S2. The blending of polyvinyl chloride, nitrile rubber, carbon black, paraffin, anti-aging agent, accelerator and plasticizer is carried out on the internal mixer. 168℃~175℃,

[0072] S3. Cord cloth gluing, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com