Application of graphene with special structure in preparation of coal mine dust suppressant

A special structure, graphene technology, applied in the direction of graphene, other chemical processes, chemical instruments and methods, etc., can solve the problems of high cost of dust suppressant, high production cost, large water consumption, etc., to achieve safe oxidation process, The effect of low cost and low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A dust suppressant for coal mines, comprising:

[0044] Sodium dodecylbenzenesulfonate: 2%;

[0045] Fatty alcohol polyoxyethylene ether: 1%;

[0046] Graphene with special structure: 0.1%;

[0047] Aqueous solution: make up 100%.

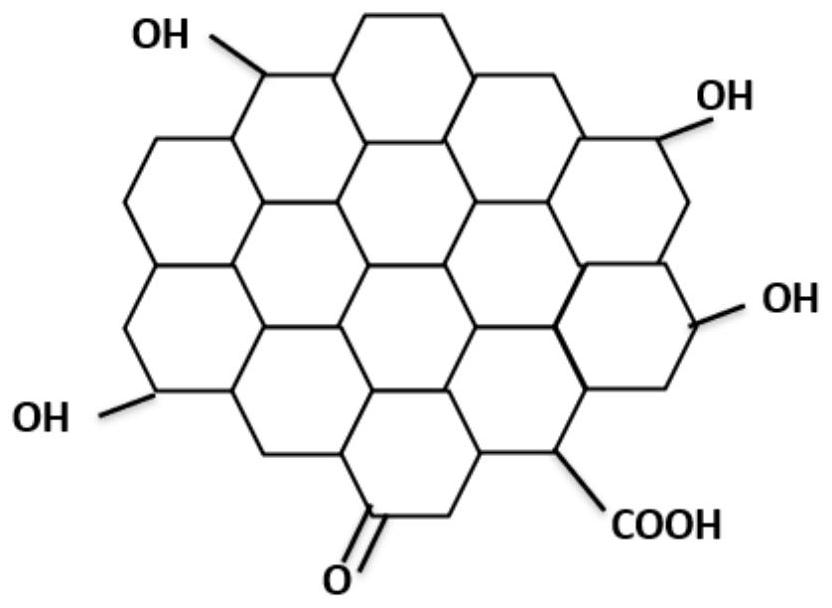

[0048] The graphene of described special structure is prepared by the method comprising the following steps:

[0049] Add 9g flake graphite to 270ml of sulfuric acid solution with a concentration of 60%, fully stir for 30min under ice-water bath, then add 9gKMnO 4 , continue to stir for 30min under ice-water bath conditions, then slowly raise the temperature to 30°C for 30min, then slowly add 200ml of deionized water dropwise, after the dropwise addition is completed, raise the temperature to 80°C and stir for 30min, then lower the temperature to room temperature, and then add a large amount of deionized water Ionized water was used to terminate the reaction, followed by the dropwise addition of H 2 o 2 Remove unreacted KMnO 4 , and t...

Embodiment 2

[0054] A dust suppressant for coal mines, comprising:

[0055] Sodium lauryl sulfate: 2%;

[0056] Fatty alcohol polyoxyethylene ether: 1%;

[0057] Graphene with special structure: 0.1%;

[0058] Aqueous solution: make up 100%.

[0059] The graphene of described special structure is prepared by the method comprising the following steps: adding 9g flake graphite to 270ml concentration is 60% sulfuric acid solution, fully stirs 30min under ice-water bath, then adds 13.5gKMnO several times in small amounts 4 , continue to stir for 30min under ice-water bath conditions, then slowly raise the temperature to 30°C for 30min, then slowly add 200ml of deionized water dropwise, after the dropwise addition is completed, raise the temperature to 80°C and stir for 30min, then lower the temperature to room temperature, and then add a large amount of deionized water Ionized water was used to terminate the reaction, followed by the dropwise addition of H 2 o 2 Remove unreacted KMnO 4 , a...

Embodiment 3

[0064] A dust suppressant for coal mines, comprising:

[0065] Sodium fatty alcohol polyoxyethylene ether sulfate: 1%;

[0066] Fatty acid diethanolamide: 1%;

[0067] Graphene with special structure: 0.2%;

[0068] Aqueous solution: make up 100%.

[0069] The graphene of described special structure is prepared by the method comprising the following steps: adding 9g flake graphite to 270ml concentration is the sulfuric acid solution of 75%, fully stirs 30min under ice-water bath, then adds 13.5gKMnO several times in small amounts 4 , continue to stir for 30min under ice-water bath conditions, then slowly raise the temperature to 30°C for 30min, then slowly add 200ml of deionized water dropwise, after the dropwise addition is completed, raise the temperature to 80°C and stir for 30min, then lower the temperature to room temperature, and then add a large amount of deionized water Ionized water was used to terminate the reaction, followed by the dropwise addition of H 2 o 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com