Strengthening system and process for preparation of hydrogen peroxide p-menthane

A technology of hydrogen peroxide and p-menthane, which is applied in the field of hydrogen peroxide p-menthane preparation, can solve the problems of poor oxidation effect, insufficient mixing, and low reaction rate, so as to achieve reduced gas-liquid ratio, stable product quality, The effect of oxidation process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

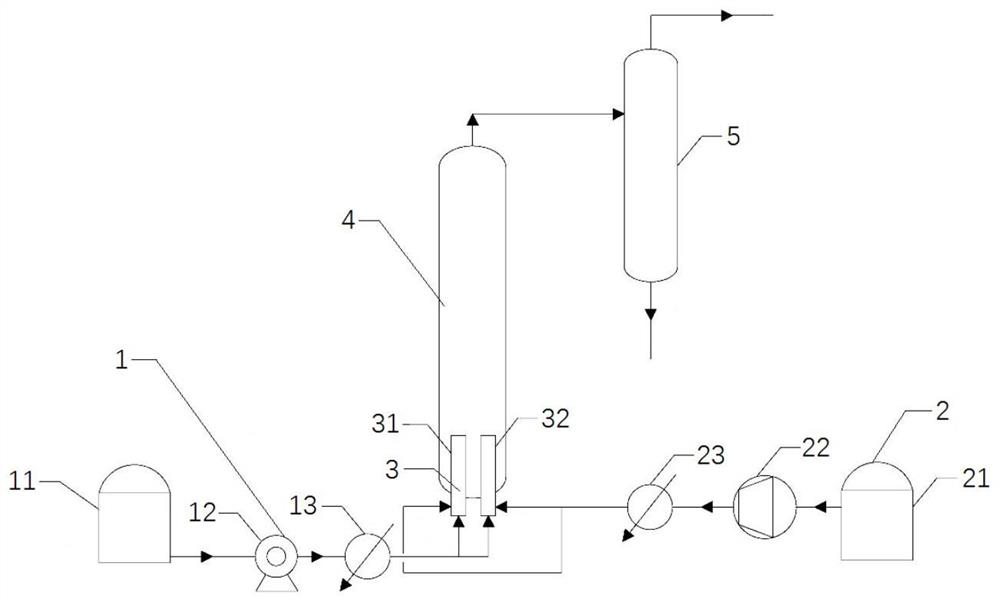

[0067] A kind of strengthening process for the preparation of menthane by hydrogen peroxide, comprising the steps:

[0068] Step 1: adding a specified amount of oxidized raw material to the liquid raw material tank 11 before running the system, and adding a specified amount of oxygen-containing gas to the gas raw material buffer tank 21;

[0069] Step 2: Start the system after the addition is completed, extract the oxidation raw material from the liquid raw material tank 11 through the feed pump 12, and extract the oxygen-containing gas from the gas raw material buffer tank 21 through the compressor 22;

[0070] Step 3: The oxidation raw material flows through the liquid feed preheater 13, the liquid feed preheater 13 heats the oxidation raw material to a specified temperature, the oxygen-containing gas flows through the gas feed preheater 23, and the gas feed preheater 23 Heating oxygen-containing gas to a specified temperature;

[0071] Step 4: After preheating, the oxidize...

Embodiment 1

[0077] Use the above-mentioned process to prepare hydrogen peroxide-menthane, wherein the oxygen-containing gas is selected air, and the oxidation raw material is selected from the p-menthane solution containing 5% mass percent hydrogen peroxide p-menthane, and the micro-interface generator 3 contains The gas-liquid ratio of oxygen gas to oxidizing raw material is 200:1, the reaction temperature in reactor 4 is 100°C, the reaction pressure is 0.1MPa, and the reaction time is 5h.

[0078] The content of the oxidation liquid containing hydrogen peroxide paramentan generated after the reaction was detected, and the test results were as follows: the mass content of hydrogen peroxide paramentan was 24.6%, and the acid value was 7.0mgKOH / L oxidation liquid.

Embodiment 2

[0080] Use the above process to prepare hydrogen peroxide p-menthane, wherein the oxygen-containing gas is selected air, and the oxidation raw material is selected to be a p-menthane solution containing 2.2% mass percent hydrogen peroxide p-menthane, and the micro-interface generator 3 contains The gas-liquid ratio of oxygen gas to oxidizing raw material is 500:1, the reaction temperature in reactor 4 is 105°C, the reaction pressure is 0.2MPa, and the reaction time is 4h.

[0081] The content of the oxidized solution containing hydrogen peroxide and menthane generated after the reaction was detected, and the test results were as follows: the mass content of hydrogen peroxide and menthane was 25.3%, and the acid value was 7.9mgKOH / L oxidized solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com