Double-furnace-door wood combustion furnace heating system

A furnace heating and furnace door technology, applied in the heating system, combustion chamber, combustion method, etc., can solve the problems of affecting indoor air quality, smoke and dust pouring into the room, increasing the cost of use, etc., to improve the heating effect and combustion efficiency , the effect of enhancing security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

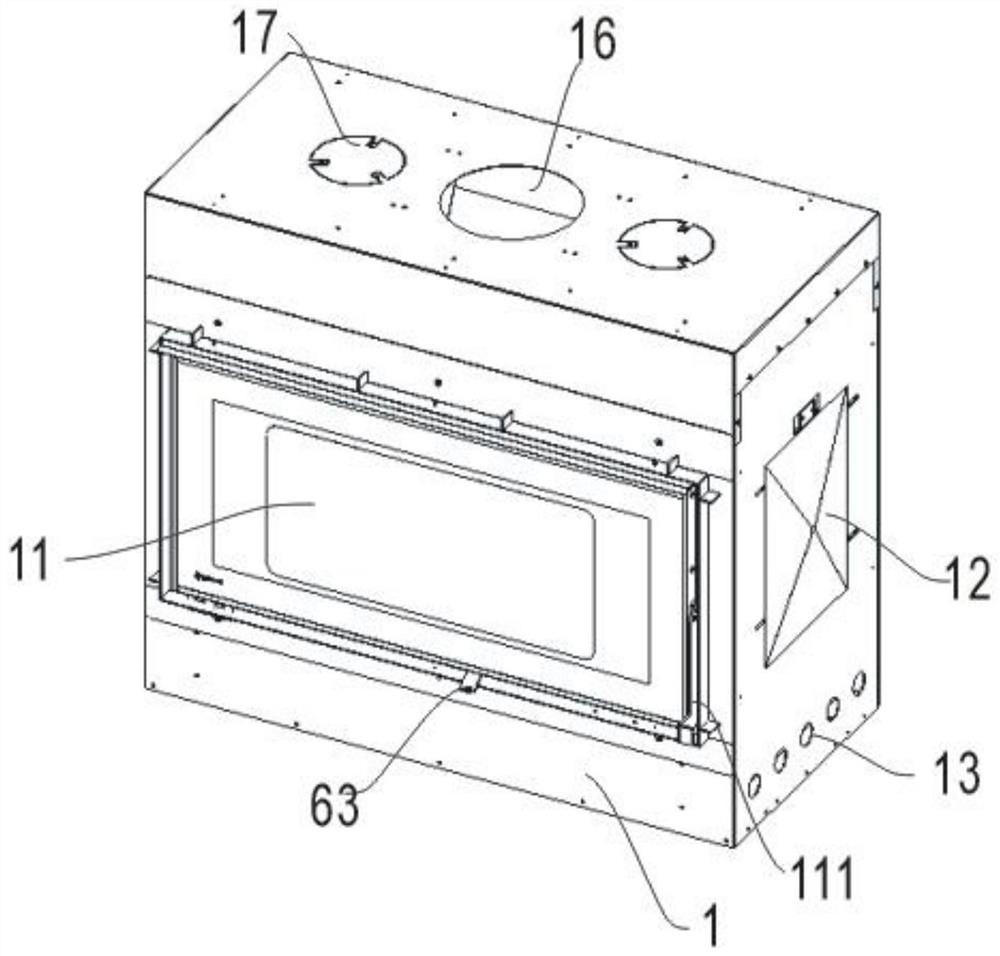

[0040] like figure 1 As shown, a double-sided furnace door blast furnace of a double-sided furnace blast furnace, a high temperature resistant observation of the housing 1, and high temperature glass is mounted. Processing. Observing the lever 63 below the gates 11 extends outside the outer casing 1 to facilitate adjusting the ventilation. The outer casing 13 is provided at the bottom of the outer casing 1, and the plurality of side vent holes 13 are distributed over the bottom side, the linear array distribution, facilitates the outer venting air tube, laying along the ground, supplying heating. Of course, the top is set to the exhaust port 16, and the heat transfer port 17, the exhaust pipe 16 is connected to the smoke pipe, and the smoke in the combustion is discharged through the smoke of the combustion chamber 4, and the heat transfer port 17 is connected to the heat pipe, will heating Loss to the heating zone.

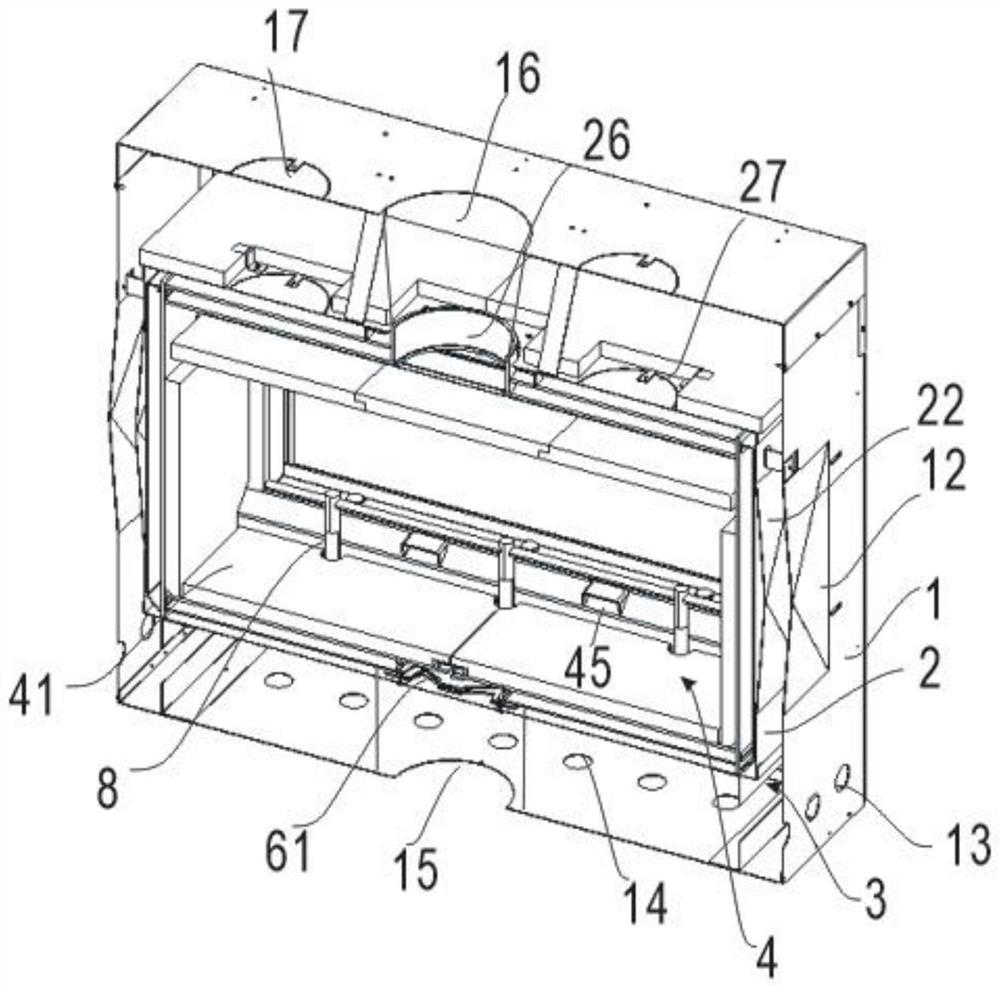

[0041] like figure 2 As shown, the inner casing 2 is embedded w...

Embodiment 2

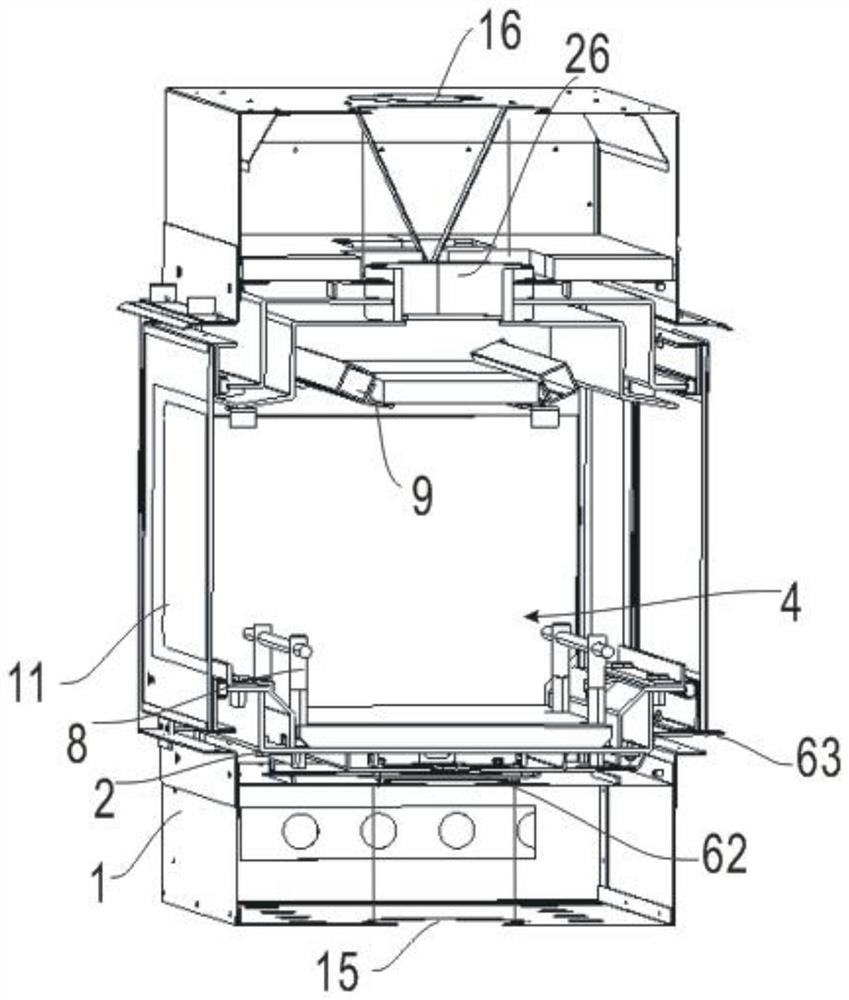

[0043] like image 3 As shown, in fact, in the first embodiment, a double-sided furnace door-fired furnace heating system, the damper plate 61 includes a vents composed of a plurality of sector circumference arrays, and the venting lever 63 is provided at the damper plate 61. The gas control valve 62, the intake control valve 62 is provided with a relatively vent, and the lever 63 extends to the outer casing 1.

[0044] like Figure 4 , Figure 5 , The intake control valve 62 and the damper plate 61 in a concentric manner, together with the installation, the damper plate 61 is provided with a mounting hole connected to the interlayer 3, the intake control valve connected to the control rod 63 has both ends 62 extend. Ventilation amount control damper plate 61, just toggle lever 63, so that the intake control relative rotational displacement between the valve 62 and the damper plate 61, with a plurality of fan-shaped hole area is increased or reduced, thereby controlling the amount of w...

Embodiment 3

[0046] like image 3 As shown in Example 1 is different from, a double-sided wood-fired oven door heating system, combustion chamber 4 is provided at the top combustion pipe 9, through the combustion tube is a square tube 9, the nozzle communication air door 61, towards wall Xiachu has a plurality of apertures. When the air vent door 61, also combustion ventilation pipe 9, and oxygen gas outputted from the plurality of small holes, the auxiliary combustion chamber 4 in the wood-fired combustion more fully, thereby improving the heating efficiency. Automatic air intake heating system, combustion more fully, less dust emission control may be 1.3g / kg in. Combustion tube 9, both sides of the oxygen feed, an intermediate hole, play a secondary combustion, thermal efficiency, reduce dust. When the cold air into the combustion chamber for heating air by heat 4 itself, by a duct for combustion air is assigned to both sides, and then into the combustion tube 9, and the sight glass 11 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com