Forebed-free blast furnace and antimony-gold concentrate treatment method using forebed-free blast furnace

A blast furnace and front bed technology, applied in the field of antimony gold concentrate treatment, no fore bed blast furnace, can solve the problems of ineffective antimony treatment, unfavorable constant temperature of blast furnace, effective purification of sulfur-containing gas, etc., to improve economic and technical indicators, smelting The effect of improving the effect, improving the yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

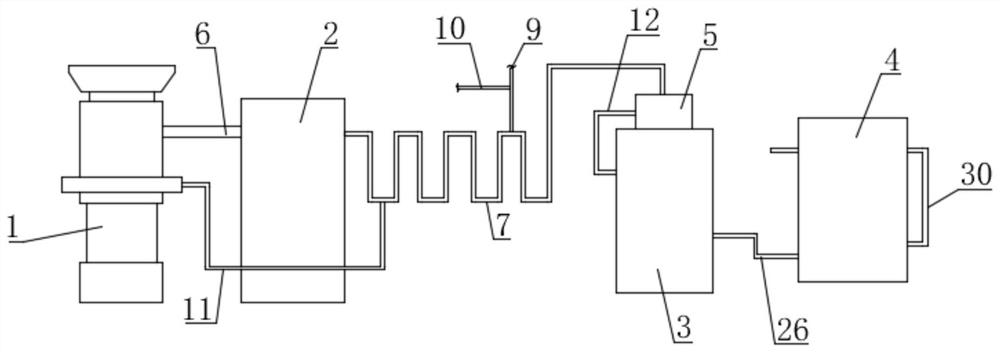

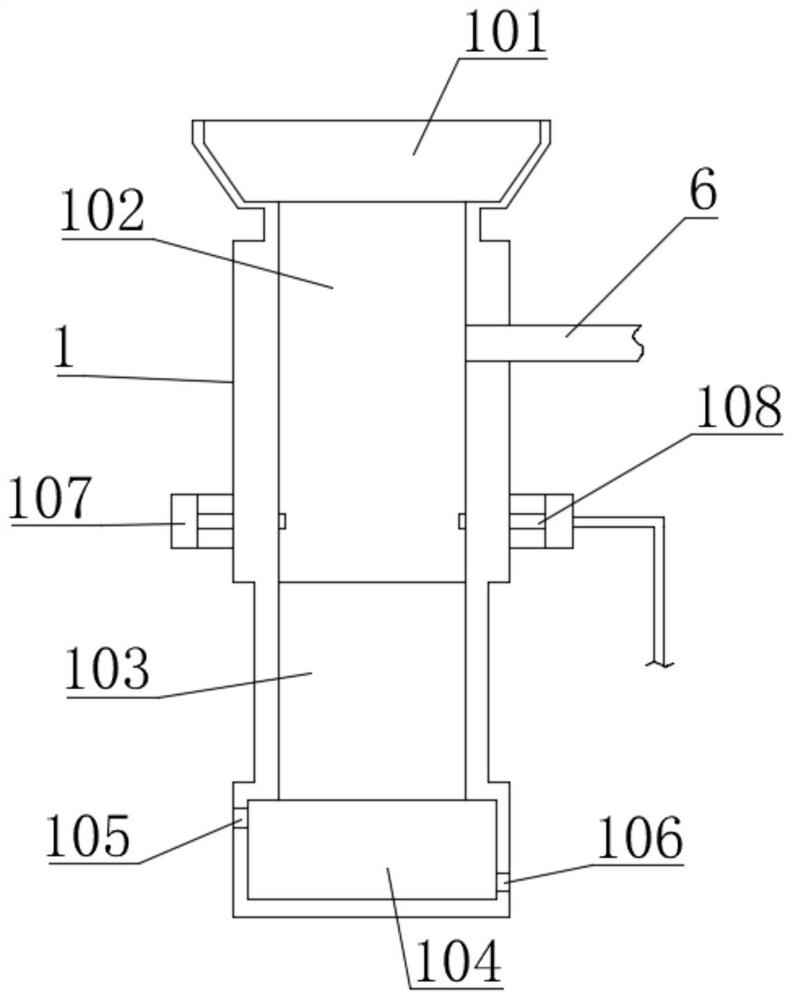

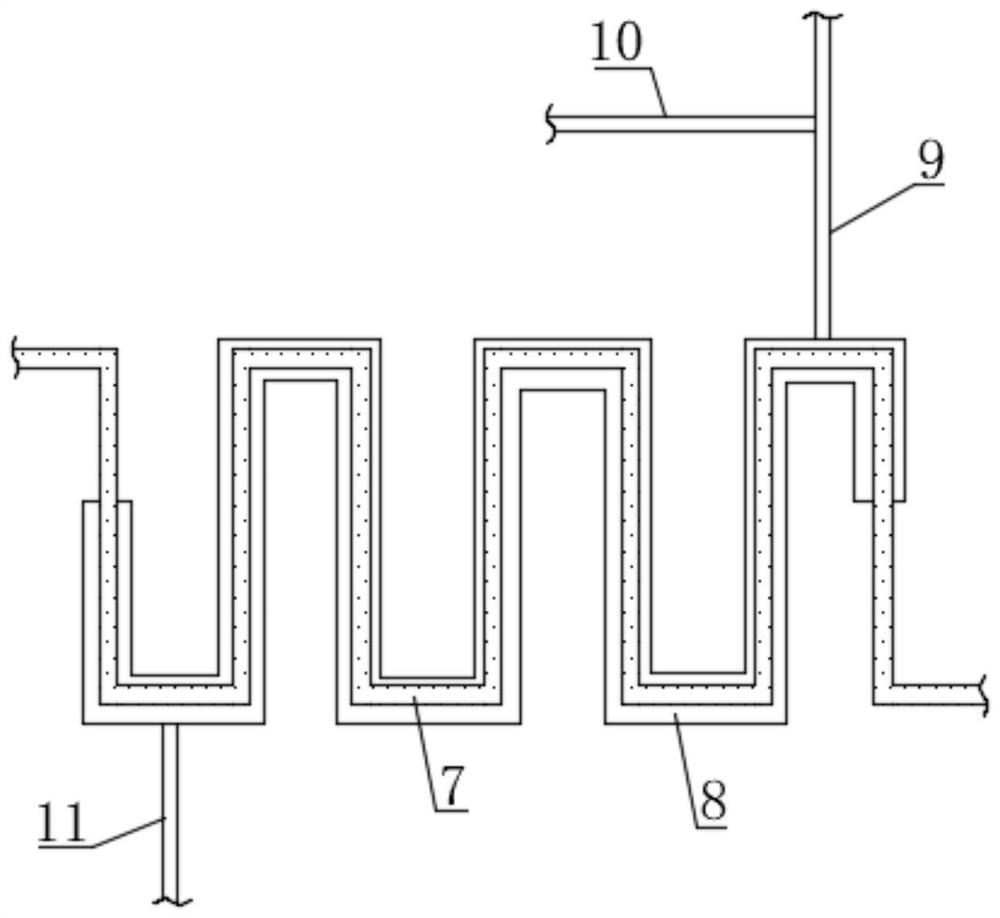

[0053] like Figure 1-12 As shown, the blast furnace without front bed proposed by the present invention comprises a blast furnace body 1, the top of the blast furnace body 1 is provided with a furnace mouth 101, and a furnace body 102, a hearth 103 and a furnace hearth 104 are arranged in the blast furnace body 1, and the blast furnace body 1 The body 1 is provided with a slag discharge port 105 and a discharge port 106 connected with the hearth 104, and the slag discharge port 105 and the discharge port 106 are provided with flashboards for sealing. The outer wall of the blast furnace body 1 is equipped with an annular wind Pipe 107, the inner peripheral surface of the annular air duct 107 is provided with multiple groups of blast pipes 108 communicating with the inside of the blast furnace body 1, and the annular air duct 107 blows air into the blast furnace body 1 through each group of blast pipes 108, so The oxygen concentration of the input air is more than 25%, and the ...

Embodiment 2

[0060] like Figure 4-6 As shown, the difference between this embodiment and Embodiment 1 is that the top inner wall of the collection box 3 is rotatably mounted with multiple sets of drive shafts 24 through bearings, and the drive shafts 24 extend downward into the corresponding collection tanks 18. On the drive shafts 24 Multiple groups of cleaning assemblies 21 are installed, and the cleaning assemblies 21 clean the first filter cloth 20. The first drive motor 23 is fixedly installed on the collection box 3 through the motor base, and the output end of the first drive motor 23 is connected to one set of drive shafts. 24 connections, the first drive motor 23 is used to drive one of the drive shafts 24, each group of drive shafts 24 is equipped with pulleys, each group of pulleys is driven by the transmission belt 25, and then the drive shaft 24 is driven by the transmission belt 25 and each group of pulleys. After the smelting operation is finished, the first drive motor 23 ...

Embodiment 3

[0063] like Figure 7 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that a limiting groove 2106 is provided in the first connecting rod 2101, and a movable block 2102 is slidably installed in the limiting groove 2106, and the limiting groove 2106 is opposite to the movable block 2102. To limit the position, the movable block 2102 slides in the limit groove 2106, the second connecting rod 2103 is inserted into the limit groove 2106 and connected with the movable block 2102, the spring 2104 is fixedly installed in the limit groove 2106, and the spring 2104 is arranged horizontally And connected with the movable block 2102, the spring 2104 is in a compressed state and exerts a thrust on the movable block 2102, and the movable block 2102 exerts a thrust on the second connecting rod 2103, so that the brush plate 2105 is against the first filter cloth 20, which helps to improve For cleaning effect, the elastic contact between the brush plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com