Pulverizing process method and pulverizing system for desulfurized limestone

A process method and technology of a milling system, applied in cleaning methods and appliances, chemical instruments and methods, grain processing, etc., can solve the problem that limestone powder cannot reach ultra-low emissions, increase limestone consumption, reduce energy consumption, The effect of avoiding dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

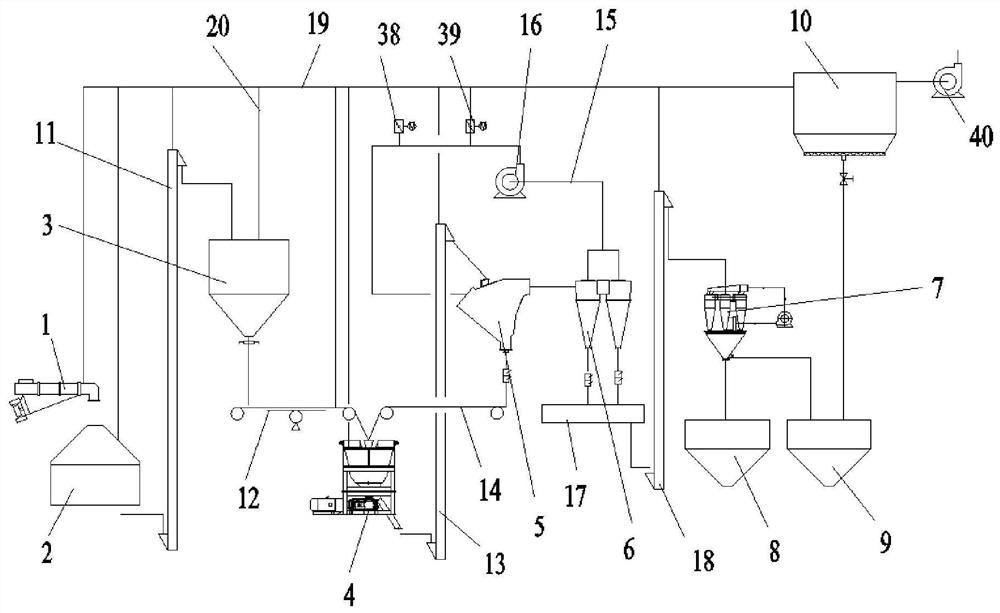

[0038] Please refer to figure 1 , a kind of pulverizing process method of desulfurized limestone, described process method comprises the following steps:

[0039] The crusher 2 crushes the limestone raw material, and the particle size after crushing is required to be 20mm-45mm;

[0040] The vertical rotary mortar mill 4 grinds the crushed limestone particles; the limestone particles are ground to the design particle size requirements. Different customers have different design particle size requirements. Therefore, for different design particle size requirements, vertical rotary mortars are required. Mill 4 is adjusted so that the limestone powder after powdering can reach the design particle size requirement;

[0041] The V-type powder separator 5 screens the ground limestone powder, and screens out large-grained limestone powders larger than the design particle size requirements and small-grained limestone powders smaller than or equal to the design particle size requirement...

Embodiment 2

[0056] Please refer to figure 1 , a pulverizing system for desulfurized limestone, the pulverizing system includes a vibrating feeder 1, a crusher 2, a raw material bin 3, a vertical rotary mortar mill 4, a V-shaped pulverizer 5, a cyclone collector 6, a special selection Powder machine 7, coarse powder finished product warehouse 8, fine powder finished product warehouse 9 and dust collector 10;

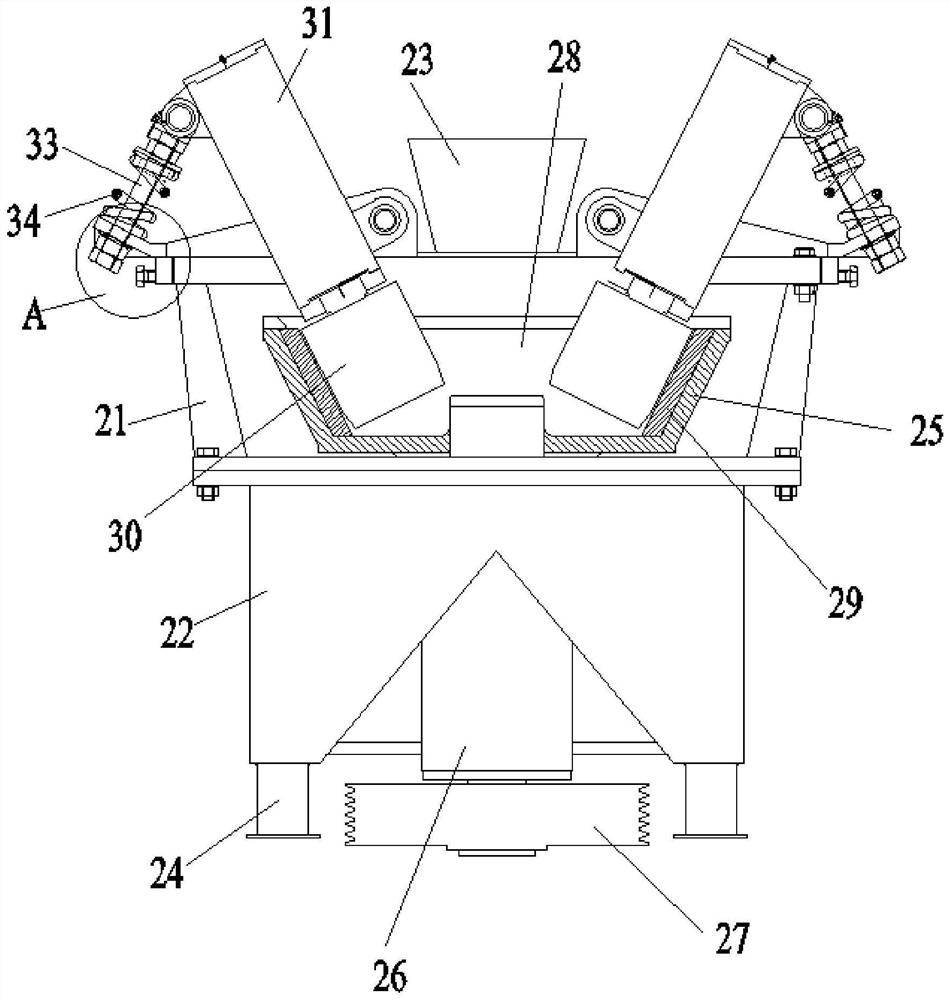

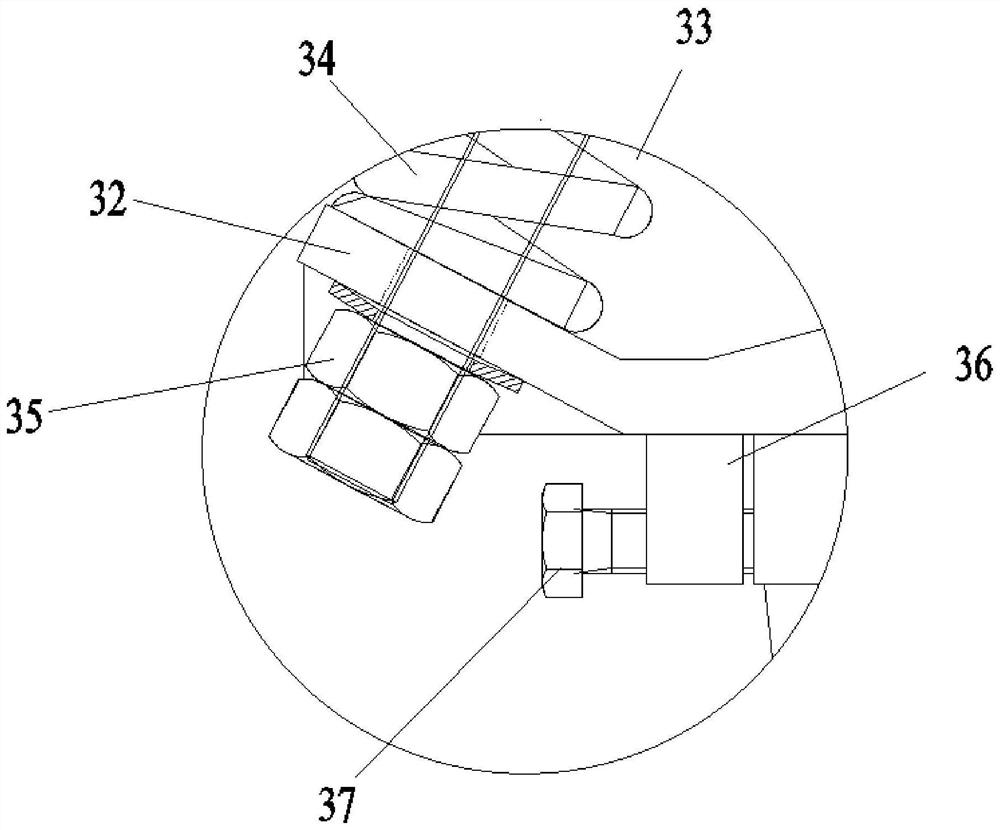

[0057] The discharge end of the vibrating feeder 1 is located directly above the feed end of the crusher 2; a first hoist is provided between the discharge end of the crusher 2 and the feed end of the raw material bin 3 11; a weighing belt conveyor 12 is provided between the discharge end of the raw material bin 3 and the feed end of the vertical rotary mortar mill 4; the discharge end of the vertical rotary mortar mill 4 is connected to the V A second hoist 13 is provided between the feed end of the V-type powder separator 5; a return material is provided between the discharge end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com