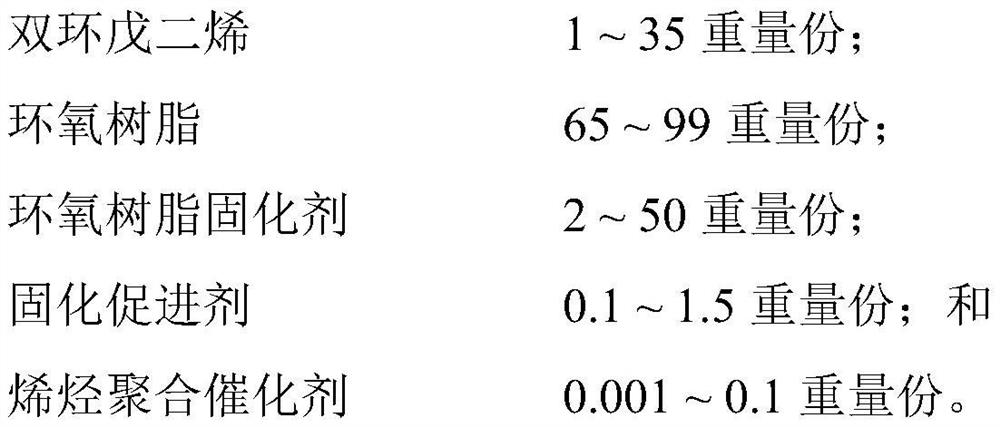

Dicyclopentadiene/epoxy resin compound and preparation method thereof

A technology of dicyclopentadiene and epoxy resin, which is applied in the field of dicyclopentadiene/epoxy resin compound and its preparation, can solve the problems of unrelated material dielectric properties, unfavorable industrial production, cumbersome operation, etc., and achieve good The effect of industrialized production basis, low production cost and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] 1. The formula of dicyclopentadiene / epoxy resin compound

[0115] Each raw material component of the dicyclopentadiene / epoxy resin compound of embodiment 1 is as follows: dicyclopentadiene 5g; Bisphenol A epoxy resin YN1828 (purchased from Jiangsu Yangnong Jinhu Chemical Co., Ltd., epoxy value 0.51-0.54) 95g; dicyandiamide curing agent 3.8g; 2-methylimidazole 0.38g; Grubbs second-generation catalyst 0.0024g; N,N-dimethylformamide 3.5g; toluene 0.25g.

[0116] 2. Preparation process of dicyclopentadiene / epoxy resin compound

[0117] The preparation technology of the dicyclopentadiene / epoxy resin compound of embodiment 1 is as follows:

[0118] (1) Stir dicyclopentadiene and epoxy resin at a high speed for 30 minutes at 40°C to make them evenly mixed;

[0119] (2) Dissolve 2-methylimidazole in N,N-dimethylformamide, add dicyandiamide curing agent into the resin solution obtained in step (1), and stir mechanically at 40°C for 90 minutes at high speed;

[0120] (3) Grubb...

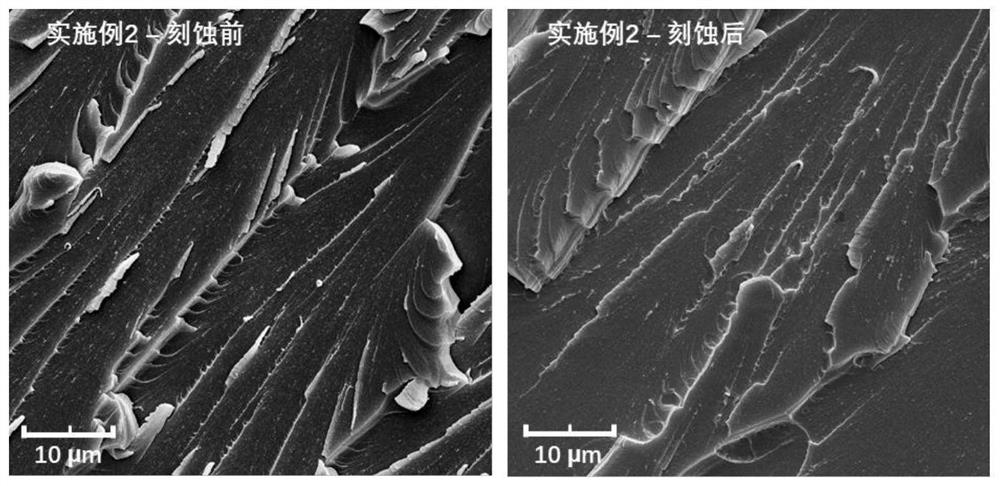

Embodiment 2

[0123] 1. The formula of dicyclopentadiene / epoxy resin compound

[0124] Each raw material component of the dicyclopentadiene / epoxy resin compound of embodiment 2 is as follows: dicyclopentadiene 10g; Bisphenol A type epoxy resin YN1828 (purchased from Jiangsu Yangnong Kumho Chemical Co., Ltd. 0.51-0.54) 90g; dicyandiamide curing agent 3.6g; 2-methylimidazole 0.35g; Grubbs second-generation catalyst 0.0049g; N,N-dimethylformamide 3.5g; toluene 0.25g.

[0125] 2. Preparation process of dicyclopentadiene / epoxy resin compound

[0126] The preparation technology of the dicyclopentadiene / epoxy resin compound of embodiment 2 is as follows:

[0127] (1) Stir dicyclopentadiene and epoxy resin at a high speed for 30 minutes at 40°C to make them evenly mixed;

[0128] (2) Dissolve 2-methylimidazole in N,N-dimethylformamide, add dicyandiamide curing agent into the resin solution obtained in step (1), and stir mechanically at 40°C for 90 minutes at high speed;

[0129] (3) Grubbs secon...

Embodiment 3

[0132] 1. The formula of dicyclopentadiene / epoxy resin compound

[0133] Each raw material component of the dicyclopentadiene / epoxy resin compound of embodiment 3 is as follows: dicyclopentadiene 20g; Bisphenol A epoxy resin YN1828 (purchased from Jiangsu Yangnong Jinhu Chemical Co., Ltd., epoxy value 0.51-0.54) 80g; dicyandiamide curing agent 3.2g; 2-methylimidazole 0.33g; Grubbs second-generation catalyst 0.01g; N,N-dimethylformamide 3.0g; toluene 0.35g.

[0134] 2. Preparation process of dicyclopentadiene / epoxy resin compound

[0135] The preparation technology of the dicyclopentadiene / epoxy resin compound of embodiment 3 is as follows:

[0136] (1) Stir dicyclopentadiene and epoxy resin at a high speed for 30 minutes at 40°C to make them evenly mixed;

[0137] (2) Dissolve 2-methylimidazole in N,N-dimethylformamide, add dicyandiamide curing agent into the resin solution obtained in step (1), and stir mechanically at 40°C for 90 minutes at high speed;

[0138](3) Grubbs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com