Acrylic acid pressure-sensitive adhesive tape and preparation method thereof

A technology of acrylic pressure-sensitive adhesive tape and acrylic pressure-sensitive adhesive, applied in the direction of pressure-sensitive film/sheet, adhesive, adhesive type, etc., can solve the problem of long production cycle, etc., and achieve the effect of shortening the delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Acrylic pressure sensitive adhesive formulation:

[0073] Butyl acrylate: 50 parts;

[0074] Lauryl acrylate: 10 parts;

[0075] Methyl methacrylate: 15 parts;

[0076] Acrylic acid: 4 parts;

[0077] Azobisisobutyronitrile: 0.5 parts;

[0078] Ethyl acetate: 100 parts.

[0079] Substrate: 50umPET;

[0080] Mixed solution: 100 parts of acrylic pressure sensitive adhesive, 1 part of methyl etherified melamine formaldehyde resin, 0.06 part of p-toluenesulfonic acid, 70 parts of ethyl acetate;

[0081] Adhesive layer thickness: 30um;

[0082] Oven temperature: 100°C;

[0083] Coating speed: 40m / min;

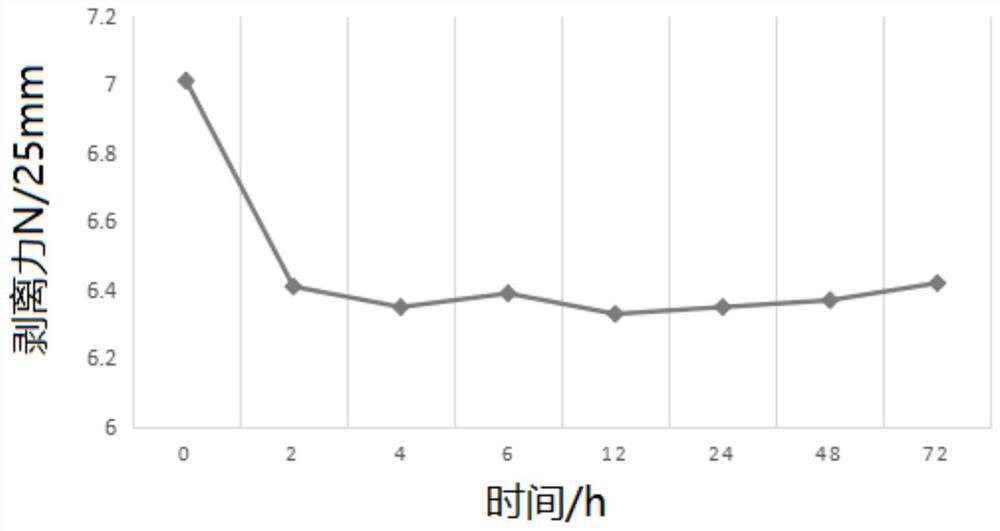

[0084] Monitor the peel force data immediately after the tape is rewound, see the data figure 1 and table 1 below:

[0085] Table 1

[0086] serial number 1 2 3 4 5 6 7 8 time h 0 2 4 6 12 24 48 72 Peel force N / 25mm 7.01 6.41 6.35 6.39 6.33 6.35 6.37 6.42

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com