Mixed solid waste pile point soil pollution risk management and control method based on horizontal barrier technology

A soil pollution and horizontal technology, applied in the sewer system, waterway system, water supply device, etc., can solve the problems of discarded tennis ball pollution, hidden danger of pollutant diffusion, insufficient heat preservation effect, etc., achieve good crack resistance and earthquake resistance, and facilitate walking maintenance , the effect of low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

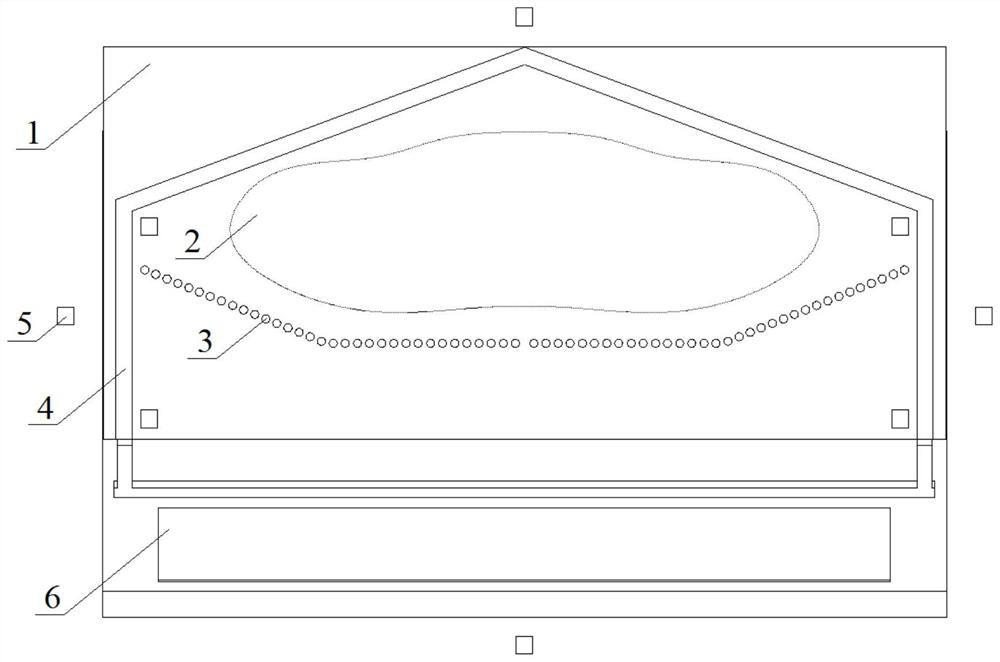

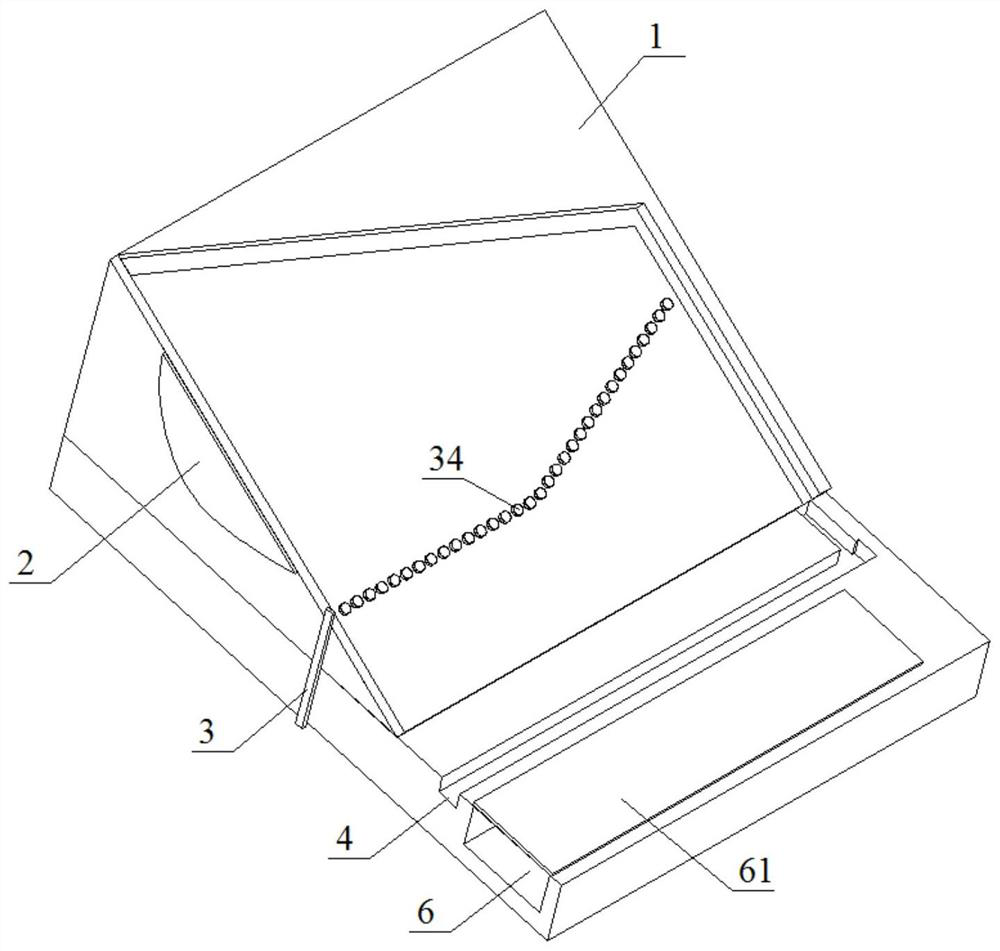

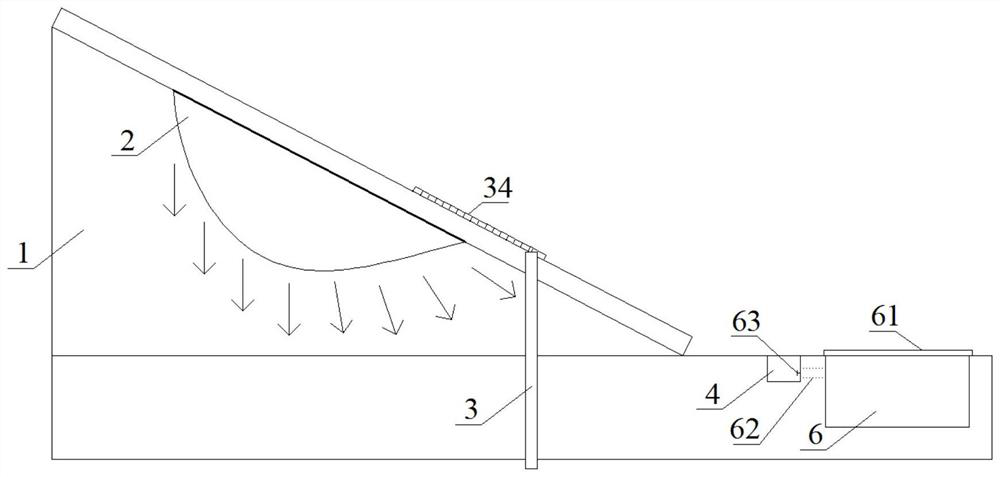

[0035] The risk control method for soil pollution at mixed solid waste dump sites based on horizontal barrier technology includes the following steps:

[0036] S1 site selection and leveling site: Select Banpo Slope 1 with a slope of 7° and no development plan in the near future, and level off Banpo Slope 1 to remove plants;

[0037] S2 Excavation of solid waste pile point: A row of cement-soil mixing piles 3 is evenly arranged 5m downstream of the preset solid waste pile point 2. In the natural continuous anti-seepage clay layer 3 meters below the surface, the permeability coefficient of the natural continuous anti-seepage clay layer in this area is low, which is 10 -7 cm / s, and then excavated along the vertical direction of the half slope with a volume of 3000m 3 The solid waste pile point 2 is arranged in an arc at the bottom of the solid waste pile point 2, and a high-density polyethylene film HDPE is laid on the bottom of the solid waste pile point 2. The high-density po...

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, the difference lies in that the slopes of the selected half-slope bodies are different.

[0043] S1 site selection and leveling site: Select Banpo Slope 1 with a slope of 15° and no development plan in the near future, and level off Banpo Slope 1 to remove plants;

Embodiment 3

[0045] This embodiment is basically the same as Embodiment 1, the difference lies in that the slopes of the selected half-slope bodies are different.

[0046] S1 site selection and leveling site: Select Banpo Slope 1 with a slope of 20° and no development plan in the near future, and level off Banpo Slope 1 to remove plants;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com