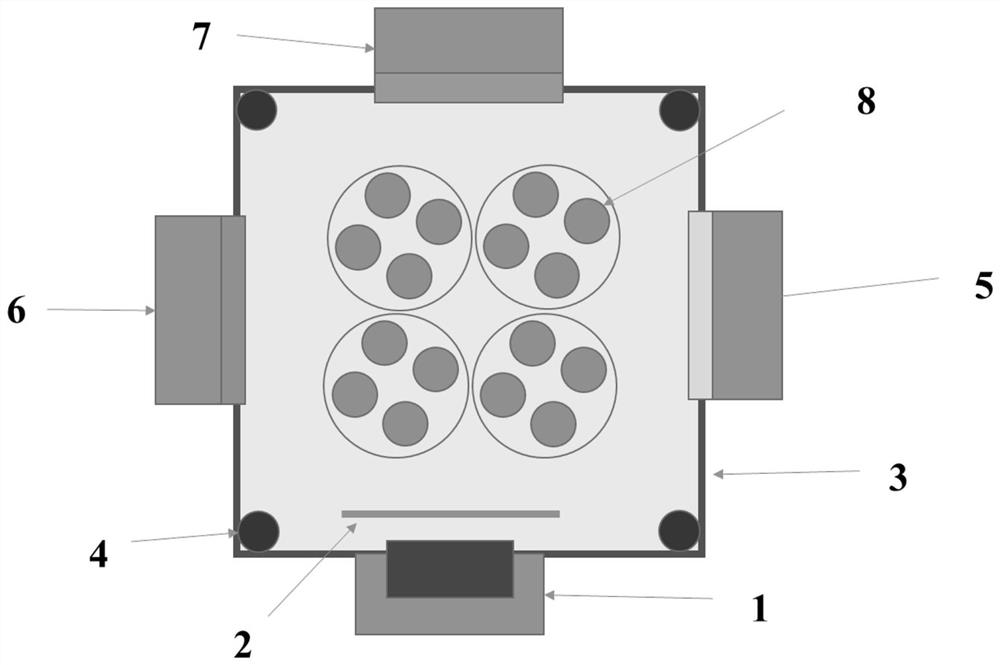

Intelligent gasket with piezoelectric sensor for bolt pre-tightening force test and preparation method of intelligent gasket

A technology of piezoelectric sensor and bolt pre-tightening force, applied in force/torque/power measuring instrument, measuring torque/torsion force during tightening, instrument and other directions, which can solve the problems of insufficient toughness and poor wear resistance of piezoelectric coating materials , to achieve the effect of reducing production cost, reducing corrosion, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

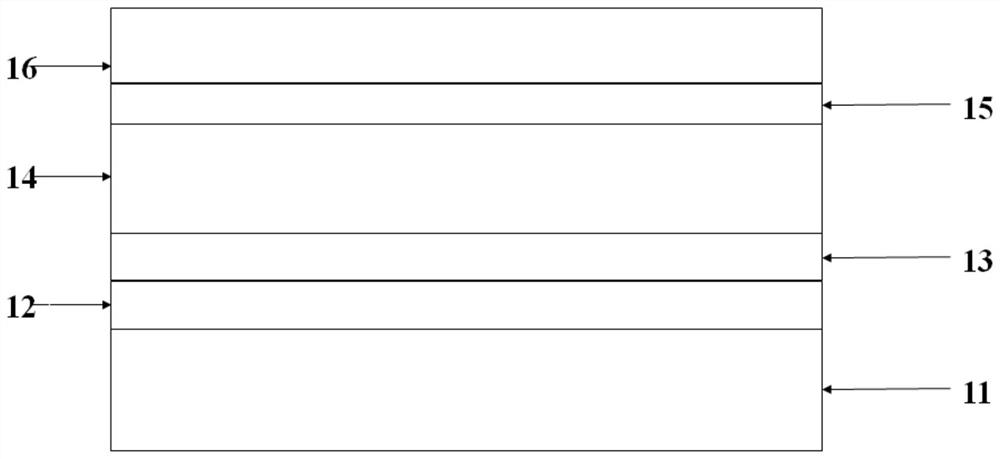

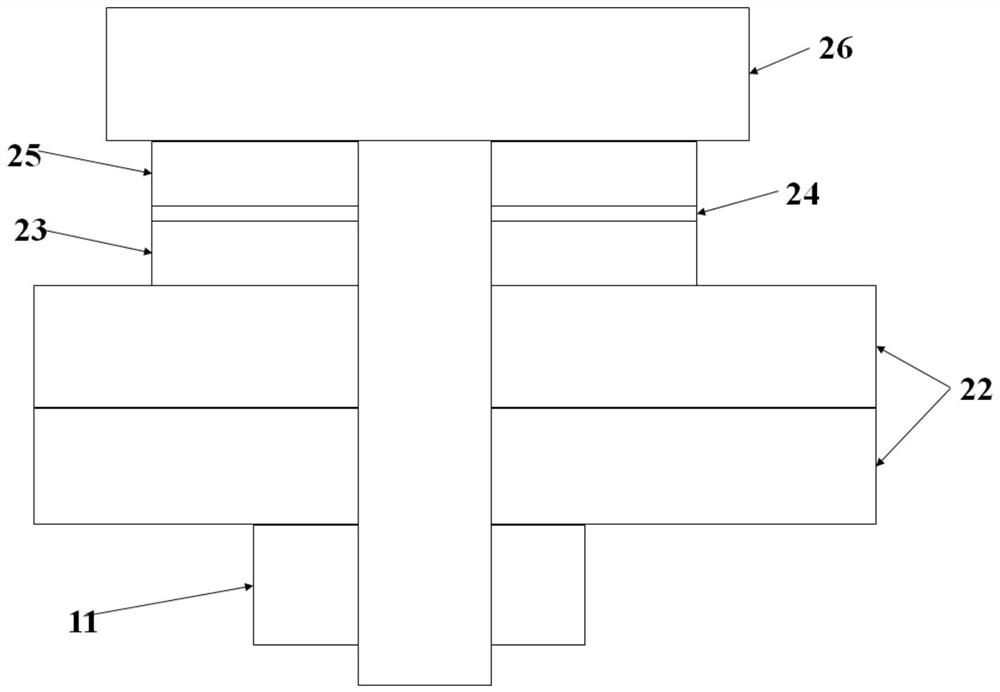

Embodiment 1

[0031] Example 1: At 100°C, in an argon and hydrogen environment, plasma etching is performed on the polished gasket; after the etching is completed, the arc discharge method is first used to prepare the hardening layer of the CrN gasket, and the deposition pressure is 0.1 Pa, the current is 50A, the thickness of the coating is 2 microns, and the hardness of the coating is 15GPa; followed by the preparation of the ZnO piezoelectric functional composite layer, first depositing a 0.5 micron Ti crystallization induction layer at 0.3Pa; then depositing 5 at 1-3Pa - ZnO piezoelectric layer of 20 microns, on the basis of the piezoelectric layer, a 2 micron AlCrO protective layer is deposited; finally, a wear-resistant conductive Cr / CrN coating is prepared, with a thickness of 3 microns and a single layer of Cr layer thickness of 3 nanometers , the thickness of the CrN layer is 7 nanometers, the modulation period is 10 nanometers, the insulation resistance is less than 1000 ohms, and ...

Embodiment 2

[0032] Example 2: Perform plasma etching on the polished gasket at 150°C in an argon and hydrogen environment; after etching, first use arc discharge method to prepare CrN gasket hardening layer, and the deposition pressure is 1Pa , the current is 100A, the coating thickness is 3 microns, and the coating hardness is 20GPa; then the ZnO piezoelectric functional composite layer is prepared, first depositing a 2 micron Ti crystallization induction layer at 0.5Pa; then depositing a 20 micron ZnO layer at 3Pa The piezoelectric layer is deposited on the basis of the piezoelectric layer with a 5 micron AlCrO protective layer; finally, the preparation of the wear-resistant conductive Cr / CrN coating is carried out, the thickness is 5 microns, the thickness of the single-layer Cr layer is 10 nanometers, and the thickness of the CrN layer is 10 nanometers, the modulation period is 20 nanometers, its insulation resistance is less than 1000 ohms, and its hardness is 15GPa; after the prepara...

Embodiment 3

[0033] Example 3: At 120°C, in an argon and hydrogen environment, plasma etching was performed on the polished gasket; after the etching was completed, the arc discharge method was first used to prepare the hardening layer of the CrN gasket, and the deposition pressure was 0.5 Pa, the current is 80A, the coating thickness is 2.5 microns, and the coating hardness is 16GPa; followed by the preparation of the ZnO piezoelectric functional composite layer, first depositing a 1 micron Ti crystallization induction layer at 0.4Pa; then depositing a 15 micron Ti crystallization layer at 3Pa ZnO piezoelectric layer, on the basis of the piezoelectric layer, a 2-micron AlCrO protective layer is deposited; finally, a wear-resistant conductive Cr / CrN coating is prepared with a thickness of 4 microns, a single-layer Cr layer thickness of 4 nanometers, and a CrN layer thickness of The thickness is 16 nanometers, the modulation period is 20 nanometers, the insulation resistance is less than 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com