Laminated body for outer packaging material of power storage device

A technology for electrical storage equipment and outer packaging, applied in lithium batteries, electronic equipment, transportation and packaging, etc., can solve the problems of strict formability and inability to meet, and achieve the effect of improving chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

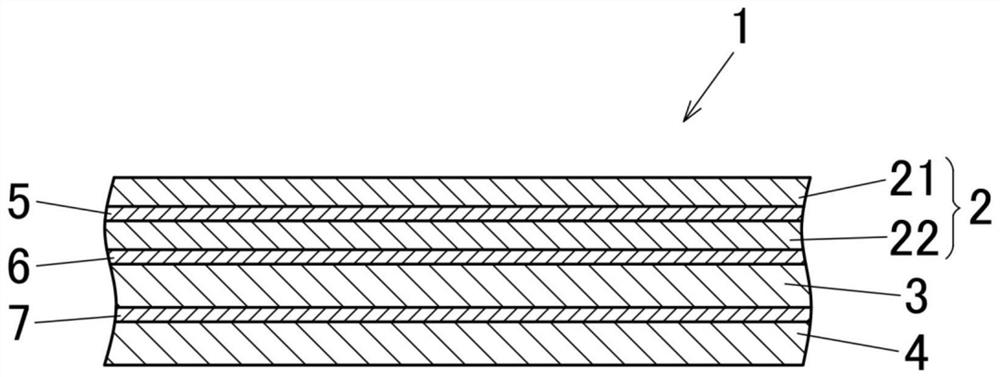

[0128] On both sides of an aluminum foil (barrier layer 3) with a thickness of 40 μm, a chemical conversion treatment liquid composed of polyacrylic acid, a trivalent chromium compound, water, and alcohol was applied and dried at 180° C. 10mg / m 2 . In addition, as the aluminum foil, A8021-O material (JIS H4160 (2006)) was used.

[0129] Furthermore, a two-component curing polyurethane adhesive (second adhesive layer 6) with a thickness of 4 μm was applied by dry lamination on one surface of the aluminum foil, and stretched nylon with a thickness of 15 μm was attached. Membrane (polyamide membrane layer 22).

[0130] Furthermore, a polyester polyurethane-based adhesive (adhesive layer 5 between substrates) with a thickness of 4 μm was applied on the surface of the stretched nylon film by dry lamination, and a stretched nylon film with a thickness of 12 μm was attached. Polyethylene terephthalate (PET) film (polyester film layer 21).

[0131] Furthermore, heat aging treatmen...

Embodiment 2

[0138] As a stretched polyethylene terephthalate (PET) film, the following film is used: the tensile breaking strength of MD is 280 MPa, the tensile breaking strength of TD is 276 MPa, that is, the sum of the two is 556 MPa, and the tensile breaking strength of TD is 556 MPa. The ratio of the tensile strength at break to the tensile strength at break in MD was 0.99, the tensile elongation at break in MD was 171%, and the tensile elongation at break in TD was 158%.

[0139] As the stretched nylon film, the following film is used: the tensile breaking strength of MD is 280MPa, the tensile breaking strength of TD is 322MPa, that is, the sum of the two is 602MPa, the tensile elongation at break of MD is 140%, and the tensile breaking strength of TD is 140%. The tensile elongation at break was 120%, the hot water shrinkage of MD was 3.6%, and the hot water shrinkage of TD was 4.2%.

[0140] Except having used the above-mentioned material, it carried out similarly to Example 1, and ...

Embodiment 3

[0142]As a stretched polyethylene terephthalate (PET) film, the following film is used: the tensile breaking strength of MD is 271 MPa, the tensile breaking strength of TD is 254 MPa, that is, the sum of the two is 525 MPa, and the tensile breaking strength of TD is 525 MPa. The ratio of the tensile strength at break to the tensile strength at break in MD was 0.94, the tensile elongation at break in MD was 155%, and the tensile elongation at break in TD was 151%.

[0143] As the stretched nylon film, the following film is used: the tensile breaking strength of MD is 276MPa, the tensile breaking strength of TD is 320MPa, that is, the sum of the two is 596MPa, the tensile elongation at break of MD is 120%, and the tensile breaking strength of TD is 120%. The tensile elongation at break was 110%, the hot water shrinkage of MD was 3.4%, and the hot water shrinkage of TD was 4.2%.

[0144] Except having used the said material, it carried out similarly to Example 1, and produced the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com