Cigarette, cooling and aroma-enhancing microcapsule and preparation method and application of cooling and aroma-enhancing microcapsule

A technology of microcapsules and tobacco flavors, which is applied in the fields of application, tobacco, and e-liquid filter elements, etc. It can solve the problems that it is difficult to achieve flavor enhancement and fragrance, and the cooling range of polylactic acid film is limited, so as to enrich the cigarette aroma and simplify the processing technology , the effect of reducing the flue gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

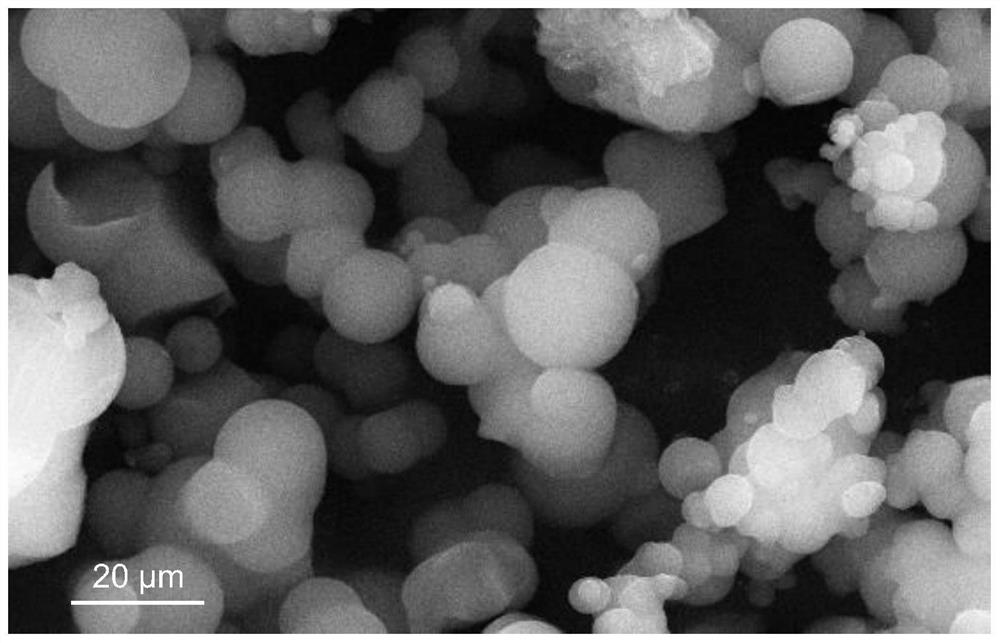

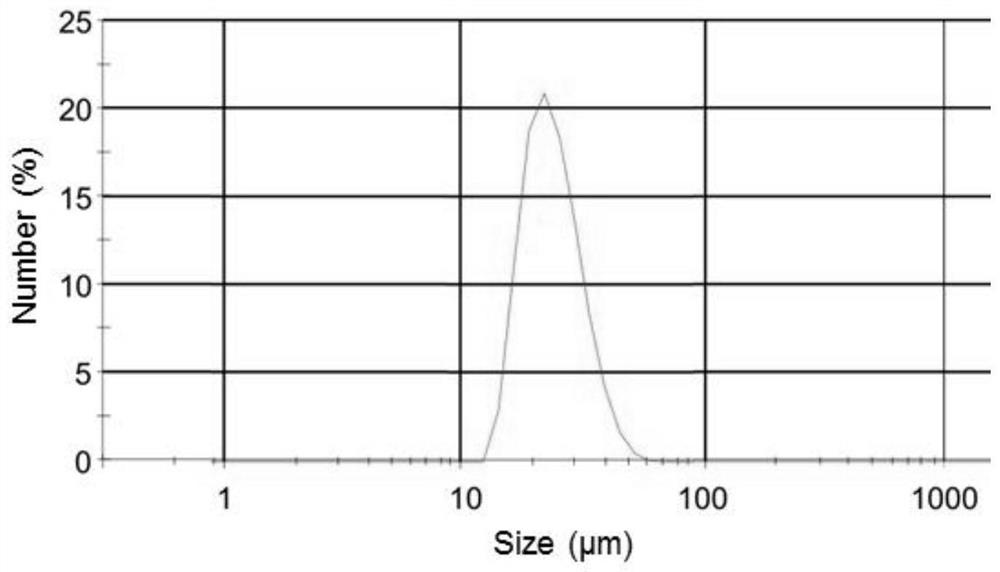

[0041] The preparation method of the temperature-lowering and flavor-enhancing microcapsules provided by the present disclosure includes the following steps:

[0042] Step (1): Dissolving the wall material raw material in dichloromethane to obtain a precursor solution, wherein the wall material raw material includes polypropylene carbonate and polybutylene carbonate, and the quality of polybutyl carbonate is polycarbonate The mass ratio of the propylene ester is 30%-50%, and the mass ratio of the wall material raw material to dioxymethane is 1:(20-30).

[0043] The mass ratio of the wall material raw material and dioxymethane in step (1) can be 1:25.

[0044] Step (2): Put the content into the precursor solution, stir evenly to obtain the first solution, wherein the mass ratio of the content to the wall material raw material is 1:(2-4), and the content is nicotine and flavoring material for tobacco and at least one of natural extracts.

[0045] Step (3): mix polyvinyl alcoho...

Embodiment 1

[0058] 2g of PPC and 0.6g of PBC were dissolved in 50mL of dichloromethane, then 1g of sweet orange oil was added and stirred evenly to obtain the first solution. An aqueous solution (500 mL) of 2 wt % polyvinyl alcohol and 0.5 wt % Span 80 was added to the Soxhlet reactor, followed by the above-mentioned first solution, and the reaction was stirred at 800 rpm and 20 kPa vacuum for 3 h. After the reaction, the solid product was collected by centrifugation, washed with water, and dried to obtain sweet orange oil microcapsules.

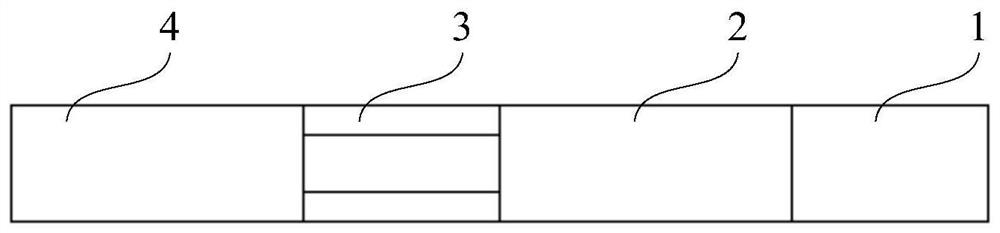

[0059] The sweet orange oil microcapsules were added to the filter rod, and then composite rolled to obtain a four-section ( image 3 Shown) finished cigarette, wherein 60mg sweet orange oil microcapsules are added in the cigarette filter stick.

Embodiment 2

[0061] Dissolve 2g of PPC and 0.8g of PBC in 50mL of dichloromethane, then add 0.8g of apple essence, and stir evenly to obtain the first solution. An aqueous solution (500 mL) of 2 wt % polyvinyl alcohol and 0.5 wt % Span 80 was added to the Soxhlet reactor, followed by the above-mentioned first solution, and the reaction was stirred at 800 rpm and 20 kPa vacuum for 3 h. After the reaction is finished, the solid product is collected by centrifugation, washed with water, and dried to obtain apple essence microcapsules.

[0062] The apple flavor microcapsules were added to the filter rod, followed by compound rolling to obtain a four-section ( image 3 Shown) cigarette finished product, wherein add 60mg apple essence microcapsules in the cigarette filter rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com