Efficient and environment-friendly aqueous film-forming foam extinguishing agent and preparation method thereof

A foam fire extinguishing agent and water film-forming technology, which can be used in fire protection equipment and other directions, can solve problems such as ecological damage and environmental pollution, and achieve the effects of good foam stability, high fire extinguishing efficiency, and not easy to corruption and deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

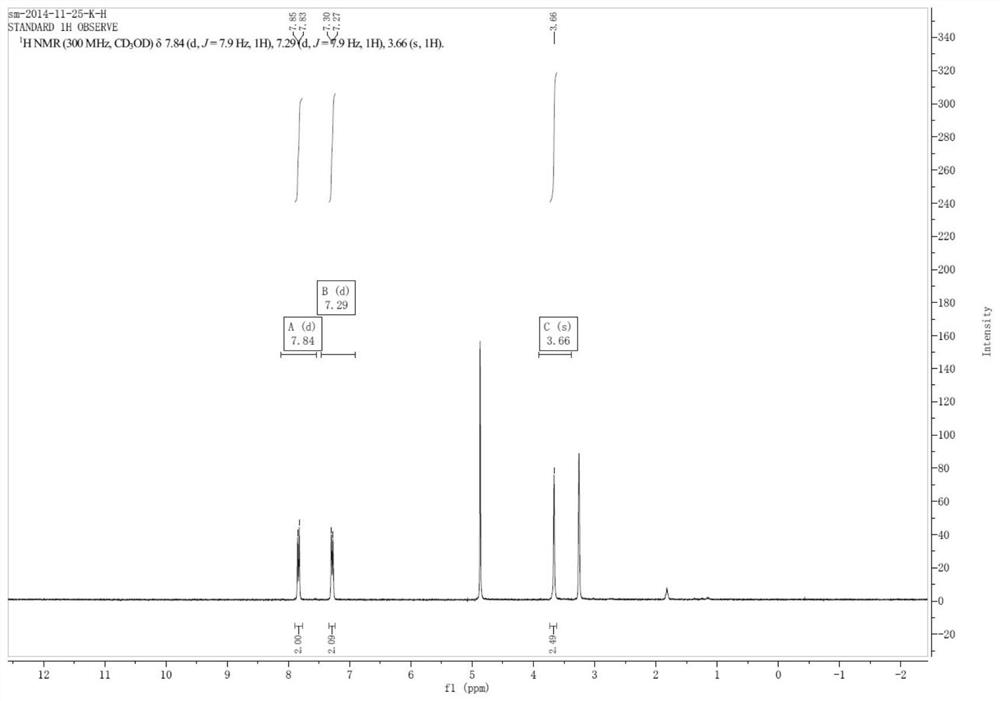

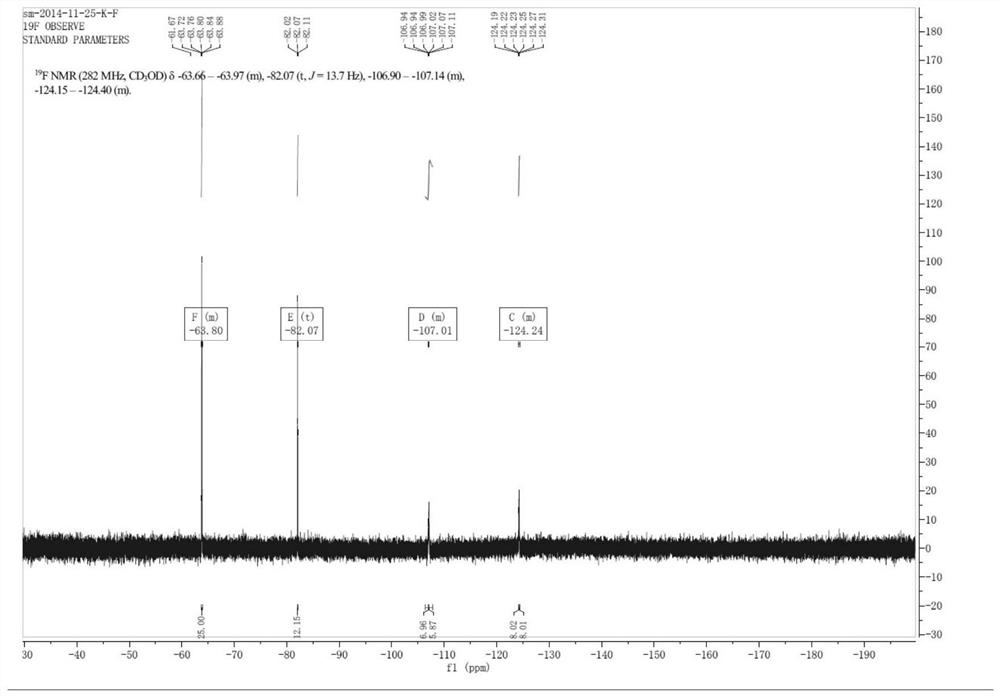

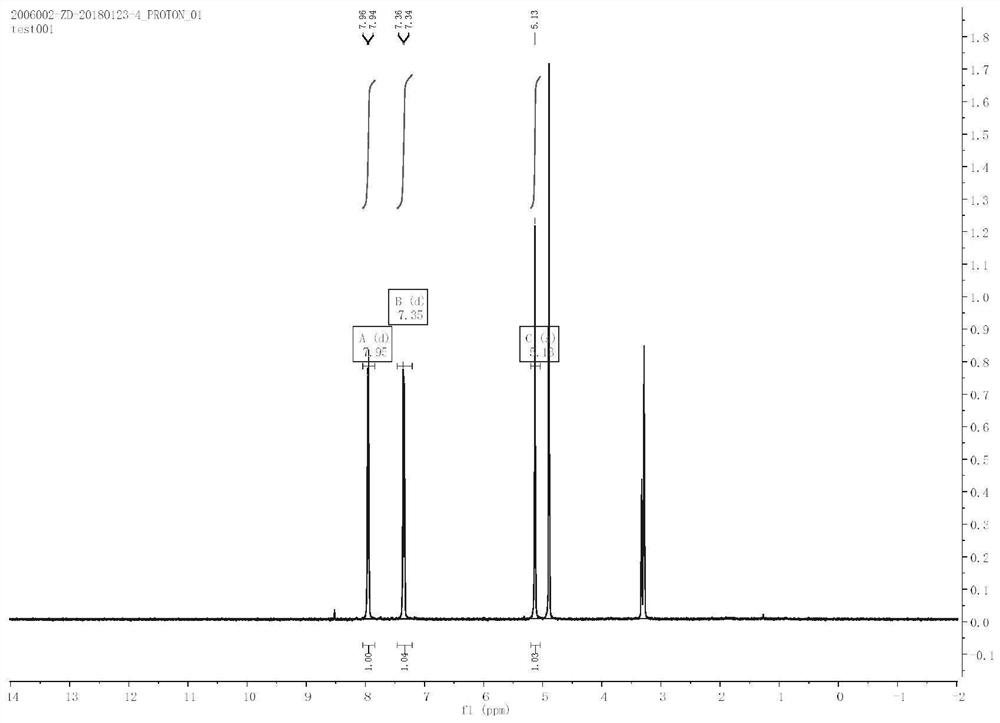

Image

Examples

Embodiment 1

[0064] Weigh respectively 1kg of benzene ring side chain anionic fluorocarbon surfactant, 1kg of cetyltrimethylammonium bromide, and 30kg of imidazoline amphoteric surfactant (imidazoline), and mix uniformly to form mixture A; Mix 5kg of alcohol monobutyl ether, 0.3kg of xanthan gum, and 30kg of water to form a mixture B; add B to A and stir; weigh 3kg of urea, mix 20kg of ethylene glycol, slowly add to A, and add sodium benzoate 0.5kg, finally add water to 100kg, stir evenly to get 100kg foam fire extinguishing agent concentrate.

Embodiment 2

[0066] Weigh respectively 1kg of alkane side chain anionic fluorocarbon surfactant, 1kg of cetyltrimethylammonium bromide, and 30kg of imidazoline, and mix uniformly to form mixture A; weigh 5kg of diethylene glycol monobutyl ether, xanthan gum Mix 0.3kg and 30kg of water evenly to form mixture B; add B to A and stir; weigh 3kg of urea and 20kg of ethylene glycol, mix evenly, slowly add to A, add 0.5kg of sodium benzoate, and finally add water to 100kg, stir Evenly, 100kg foam fire extinguishing agent concentrate can be obtained.

Embodiment 3

[0068] Weigh respectively 1kg of phencyclic ether side chain anionic fluorocarbon surfactant, 1kg of cetyltrimethylammonium bromide, and 30kg of imidazoline, and mix them uniformly to form mixture A; weigh 5kg of diethylene glycol monobutyl ether, yellow Mix 0.3kg of raw gum and 30kg of water to form mixture B; add B to A and stir; weigh 3kg of urea, 20kg of ethylene glycol, mix evenly, slowly add to A, add 0.5kg of sodium benzoate, and finally add water to 100kg , stir evenly to get 100kg foam fire extinguishing agent concentrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com