Hardening and tempering stirring kettle for mariculture solid waste and hardening and tempering method

A technology for mariculture and stirring tank, which is applied in the directions of mixer accessories, chemical instruments and methods, mixers with rotary stirring devices, etc. Replacement, enhanced biological activity, powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

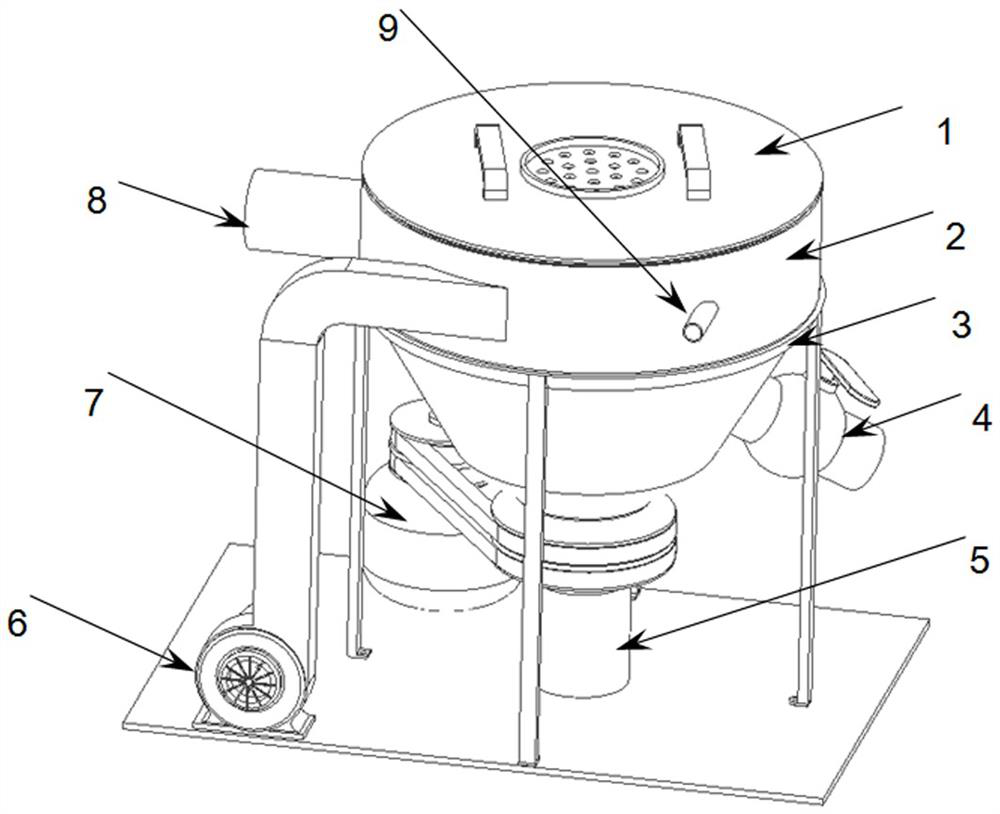

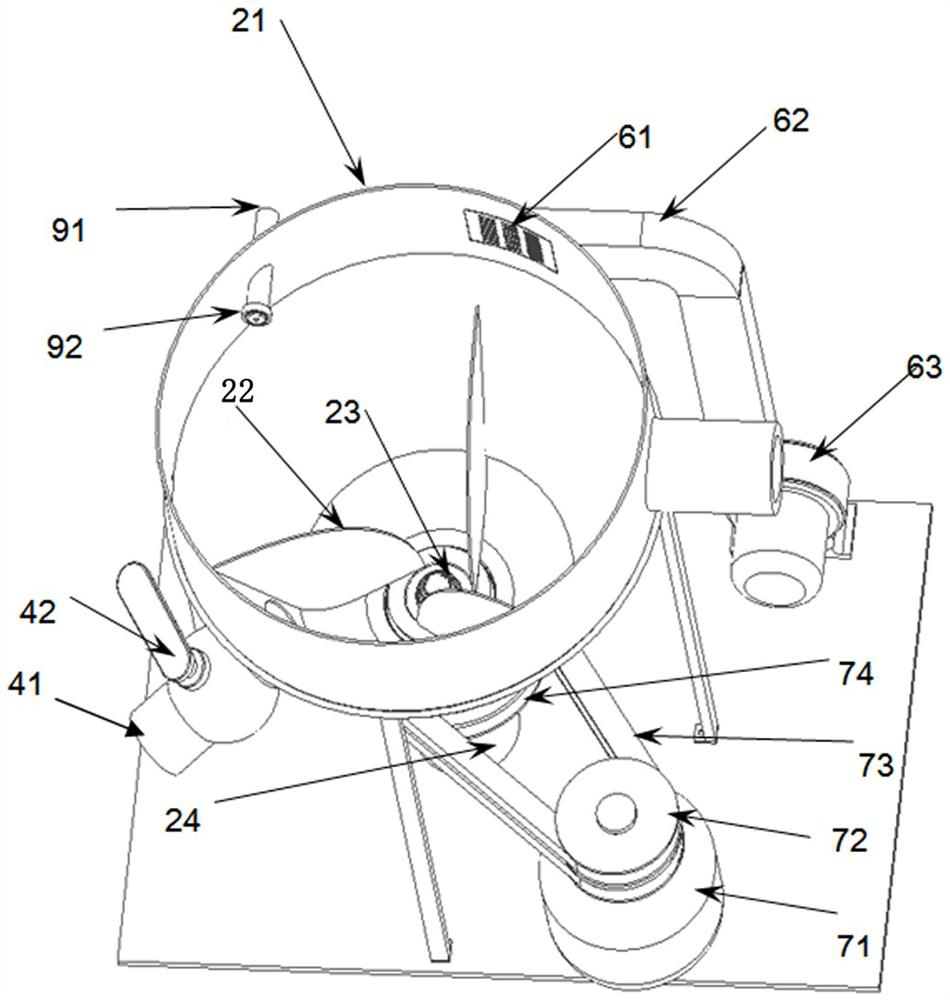

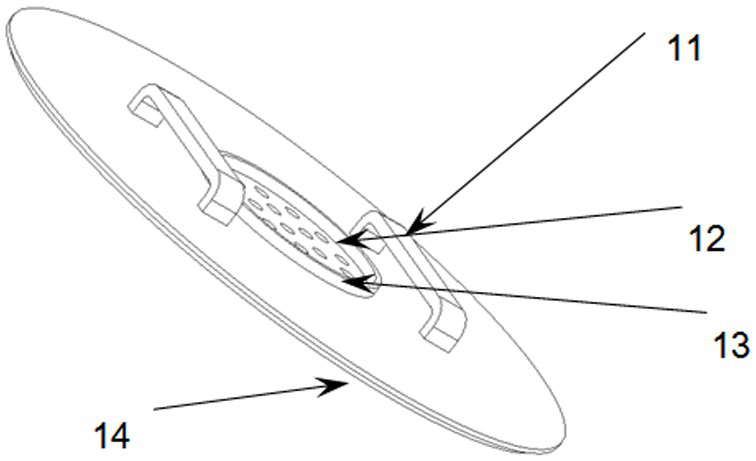

[0037] Attached below Figure 1-4 The detailed structure of this embodiment is described with technological process:

[0038] Such as figure 1 and figure 2 As shown, a tempered stirring tank for mariculture solid waste is mainly composed of a kettle cover 1, a tempered tank 2, a support 3, a discharge assembly 4, a sewer pipe 5, a hot air blower assembly 6, a power assembly 7, and a feed pipe 8 and a water supply assembly 9; wherein, the kettle cover 1 is closed at the opening of the upper end of the tempering kettle 2, and the overall weight of the above-mentioned structure is supported by the bracket 3, and the air supply port of the hot air blower assembly 6 is connected with the water supply assembly The water supply port of 9 communicates with the inner cavity of the tempering kettle 2;

[0039] The tempering kettle 2 includes a kettle body 21, a stirring impeller 22 arranged in the inner cavity of the kettle body 21, and a spherical filter cap 23, wherein the kettle ...

Embodiment 2

[0054] The structure of the device used in this embodiment is exactly the same as that of Embodiment 1, so the structural composition of the device is no longer described, and only the process is described:

[0055] The sea cucumber culture sludge is filled in a container, the mud pump is put into the container, and the outlet of the mud pump is connected with the feed pipe 8 of the tempering stirring tank. Ensure that the discharge ball valve 42 is closed, start the speed regulating motor and adjust it to 60-90 rpm, after the operation is stable, cover the kettle cover 1, turn on the mud pump to feed, and at the same time turn on the hot air blower for aeration, feed for about 1 minute, Turn off the mud pump, keep the hot air blower and stirring impeller running for 3-5 minutes, then increase the speed to 200-300 rpm. Carry out dehydration and desalination treatment of solid waste. Turn off the hot air blower and speed-regulating motor, measure the water content and salt con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com