Temperature/pH dual response type triblock polymer as well as preparation method and application thereof

A dual-response, polymer technology, applied in the field of polymers, can solve the problems of low immobilization rate and recycling rate of immobilized enzymes, low response sensitivity, limited functional monomers, etc., to achieve significant response effect, high sensitivity, high The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

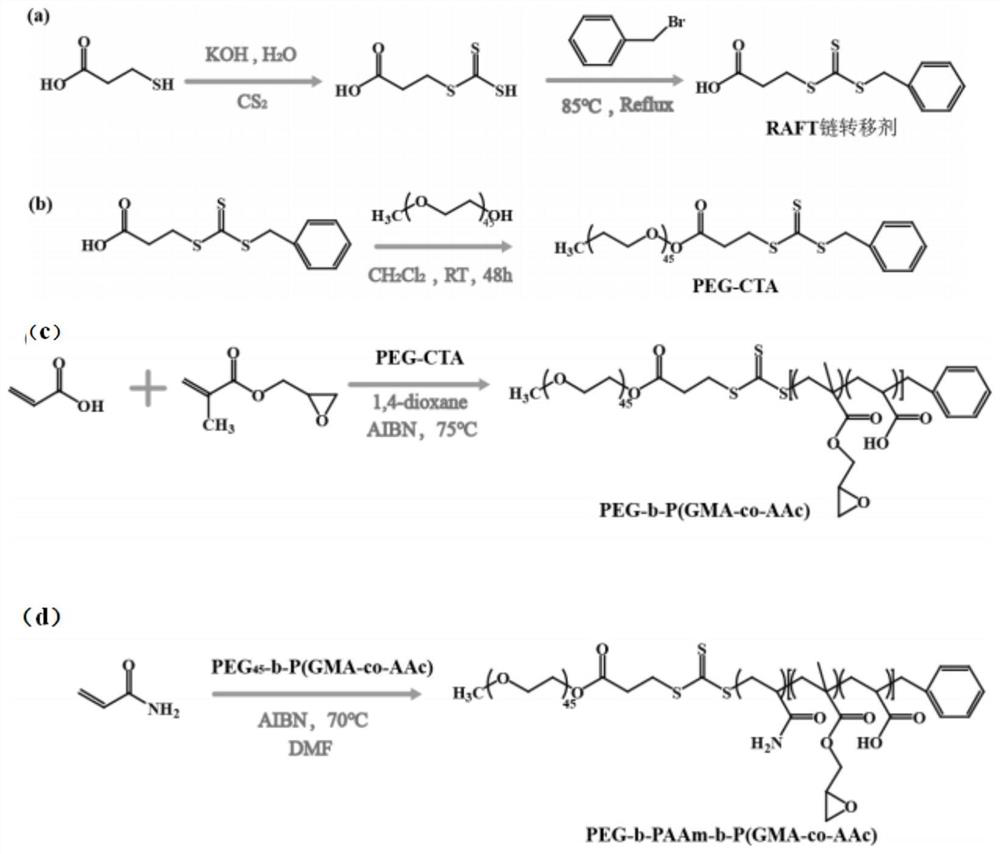

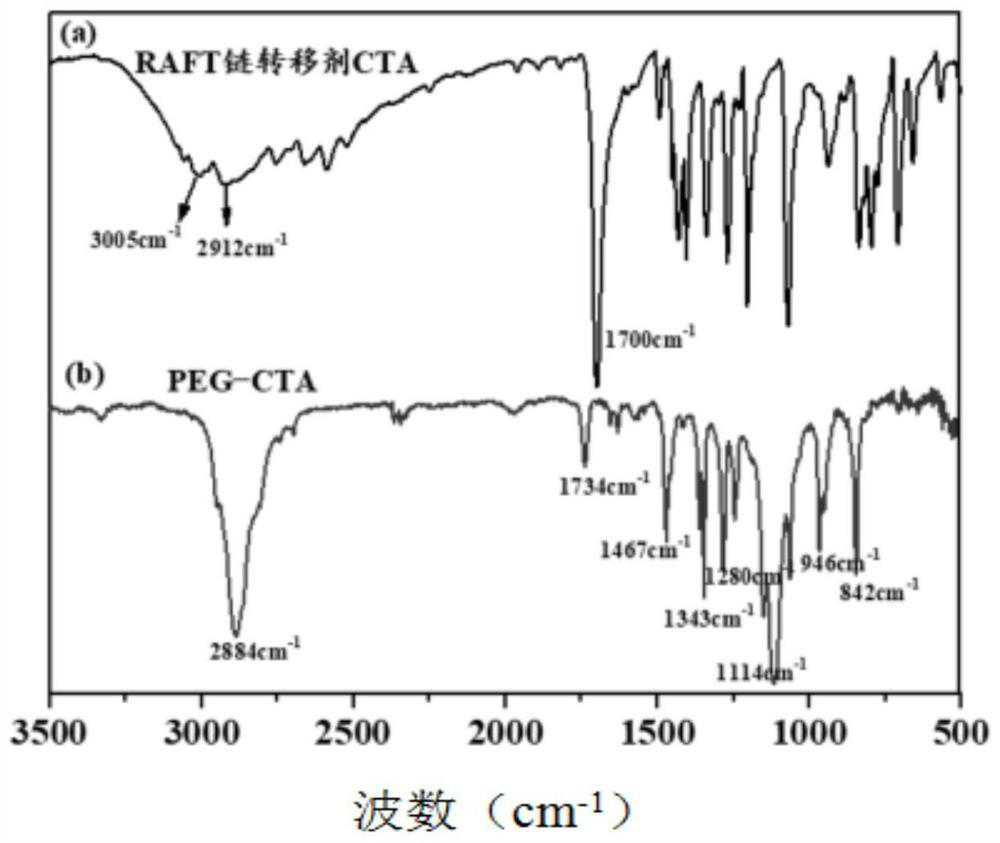

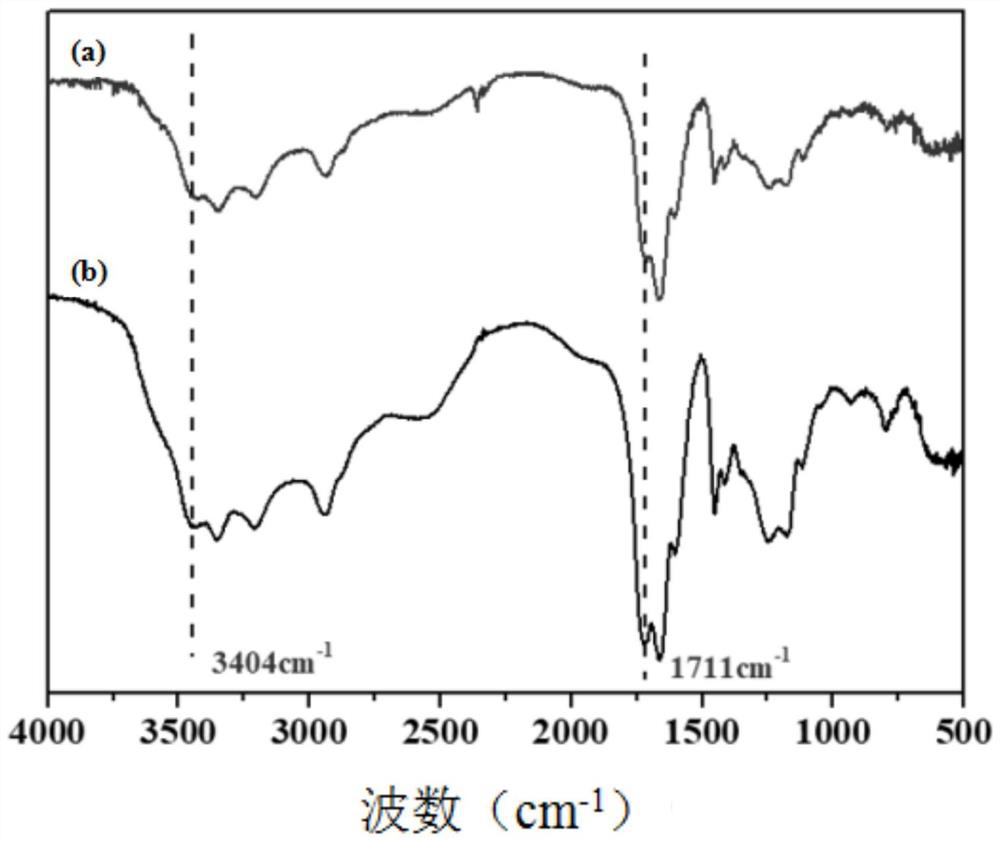

[0039] figure 1 The temperature / pH dual response type triblock polymer PEG described in the present invention 45 -b-PAAm 176 -b-P(GMA 21 -co-AAc 140 ), wherein a is the synthetic process schematic diagram of RAFT reagent (CTA), b is the synthetic process schematic diagram of the macromolecular chain transfer agent based on polyethylene glycol monomethyl ether, and c is polyethylene glycol-b-poly( Glycidyl methacrylate-co-acrylic acid) diblock polymer PEG 45 -b-P(GMA 21 -co-AAc 140 ) is a schematic diagram of the synthesis process, and d is a temperature / pH dual-responsive triblock polymer PEG 45 -b-PAAm 176 -b-P(GMA 21 -co-AAc 140 ) Schematic diagram of the synthesis process, and the specific preparation method is as follows.

[0040] (1) Preparation of RAFT reagent (CTA):

[0041] After dissolving 3.25g of potassium hydroxide KOH in 32mL of deionized water, add 2.5mL of 3-mercaptopropionic acid C 3 h 6 o 2 S, then add 4 mL of carbon disulfide CS dropwise under v...

Embodiment 2

[0051] The preparation process in steps (1)-(2) is the same as that in Example 1.

[0052] (3) Polyethylene glycol-b-poly(glycidyl methacrylate-co-acrylic acid) diblock polymer PEG 45 -b-P(GMA 21 -co-AAc 140 ) preparation:

[0053] 0.47g PEG 45 - CTA, acrylic acid (AAc, 1.38 g, 20 mmol), 1 mmol glycidyl methacrylate (GMA) and 0.0146 g initiator azobisisobutyronitrile (AIBN) were dissolved in 10 mL of 1,4-dioxane , transferred to a single-necked round-bottomed flask with a magnet, nitrogen bubbling for 30 min to remove oxygen in the reaction solution, and sealed under a nitrogen atmosphere. Then place the flask in an oil bath at 75°C and stir for 24 hours. After the reaction, the reaction is quenched with an ice-water bath, diluted with 1,4-dioxane and added to excess anhydrous ether for precipitation. The resulting The product was re-dissolved in 1,4-dioxane, and the product was precipitated with anhydrous ether. After the dissolution-precipitation was repeated three time...

Embodiment 3

[0060] The preparation process in steps (1)-(2) is the same as that in Example 1.

[0061] (3) Polyethylene glycol-b-poly(glycidyl methacrylate-co-acrylic acid) diblock polymer PEG 45 -b-P(GMA 21 -co-AAc 140 ) preparation:

[0062] 0.48g PEG 45 - CTA, acrylic acid (AAc, 1.41 g, 20 mmol), 1 mmol glycidyl methacrylate (GMA) and 0.0148 g initiator azobisisobutyronitrile (AIBN) were dissolved in 11 mL of 1,4-dioxane , transferred to a single-necked round-bottomed flask with a magnet, nitrogen bubbling for 30 min to remove oxygen in the reaction solution, and sealed under a nitrogen atmosphere. Then place the flask in an oil bath at 78°C and stir for 24 hours. After the reaction, the reaction is quenched with an ice-water bath, diluted with 1,4-dioxane and added to excess anhydrous ether for precipitation. The resulting The product was re-dissolved in 1,4-dioxane, and the product was precipitated with anhydrous ether. After the dissolution-precipitation was repeated three time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com