Lead smelting refining device with lead discharged from pot bottom

A refining device, a technology for melting lead, which is used in equipment for feeding molten metal into a casting mold, control of pouring molten metal from a ladle, waste heat treatment, etc. and other problems, to achieve the effect of less burning loss of alloy elements, stable flow rate and controllable flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

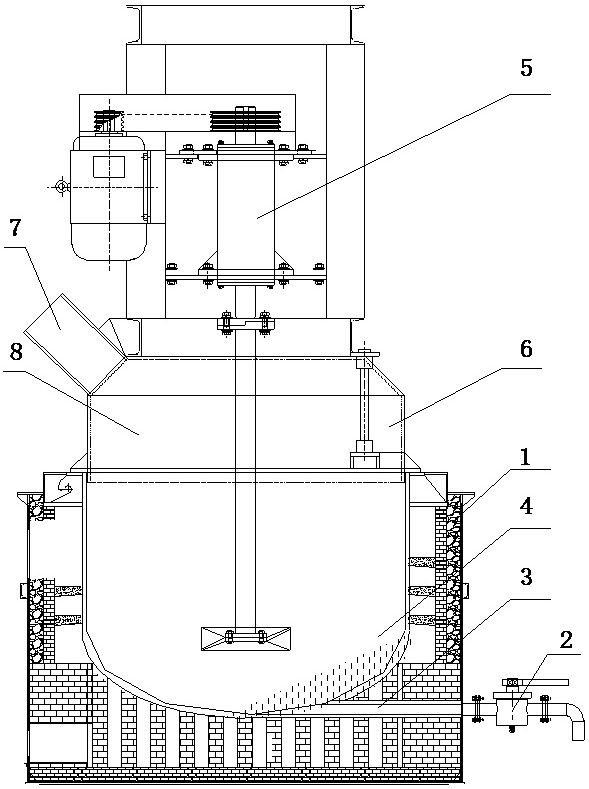

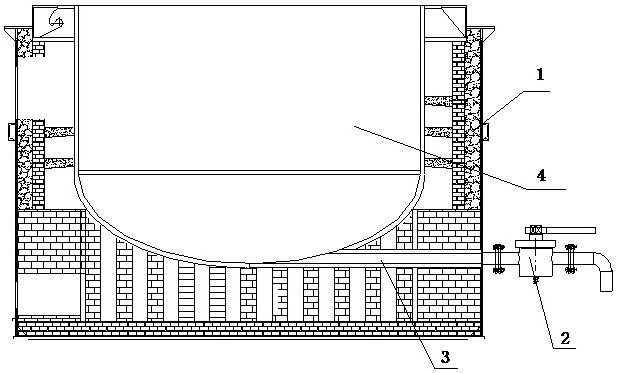

[0025] Embodiment 1: The refining device includes: a furnace body 1, a lead valve 2, a lead pipe 3, a refining pot 4, a mixer 5, a feeding port 6, a smoke outlet 7 and a pot cover 8;

[0026] The refining pot 4 is installed on the furnace body 1, and the lead valve 2 is connected to the bottom of the refining pot 4 through the lead pipe 3; The opening is closed; there is a feeding port 6 and a smoke outlet 7 on the pot cover 8, and a stirrer 5 is connected to the upper end of the pot cover 8.

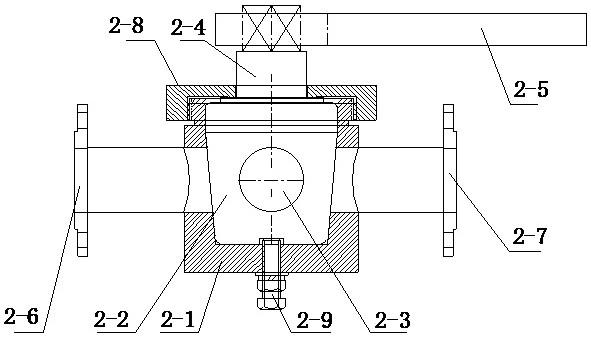

[0027] The lead release valve 2 includes: valve body 2-1, spool 2-2, spool hole 2-3, spool rod 2-4, wrench 2-5, liquid inlet 2-6, liquid outlet 2-7, valve cover 2-8 and thimble bolt 2-9;

[0028] The valve core 2-2 is located in the central hole of the valve body 2-1, and the upper end of the valve body 2-1 is connected with a valve cover 2-8, and the valve core 2-2 is locked on the valve body 2 through the valve cover 2-8. -1, there is an external thread on the upper end of the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com