A polarization-sensitive long-wave infrared subwavelength grating mdm trapezoidal absorber

A sub-wavelength grating, long-wave infrared technology, applied in instruments, optics, optical components, etc., to reduce difficulty and complexity, improve processing efficiency, and achieve the effect of ultra-wide-angle, narrow-band, and high absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

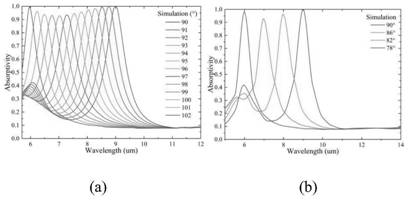

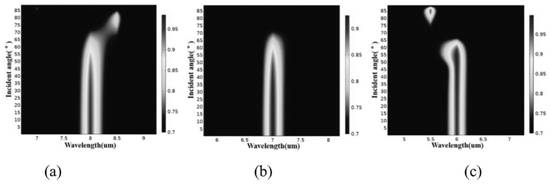

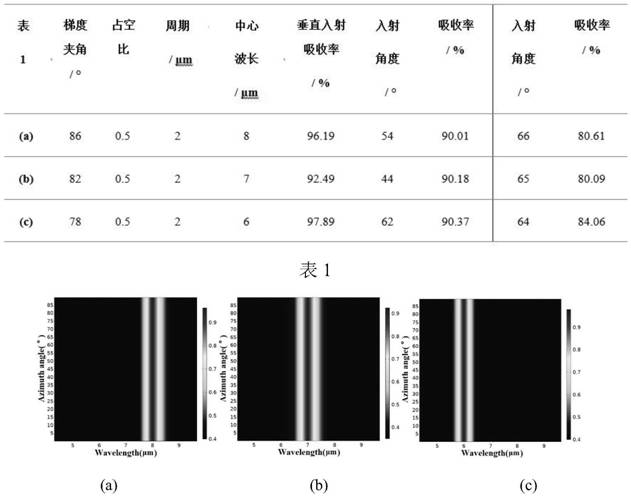

[0023] see Figures 1 to 8 , the present invention provides a technical solution: a polarized light-sensitive long-wave infrared subwavelength grating MDM trapezoidal structure absorber, comprising a zinc sulfide substrate 1, the bottom of the zinc sulfide substrate 1 is coated with an aluminum film 2, and the zinc sulfide substrate 1 is plated with an aluminum film 2. The upper part of the substrate is coated with a grating structure layer 3 which is an aluminum film, a zinc selenide film, an aluminum film, a germanium film, and an aluminum film sequentially from bottom to top, and the grating structure layer 3 has a trapezoidal structure.

[0024] In this embodiment, preferably, a grating structure is first etched on the upper surface of the zinc sulfide substrate 1 by using a mask lithography process.

[0025] In this embodiment, preferably, after the aluminum film, the zinc selenide film, the aluminum film, the germanium film, and the aluminum film are respectively plated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com