Method for welding ceramic and nickel-based alloy

A technology of nickel-based alloy and nickel alloy, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of reducing thermal stress, achieve the effects of improving wettability, energy saving and environmental protection of the process, and avoiding pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

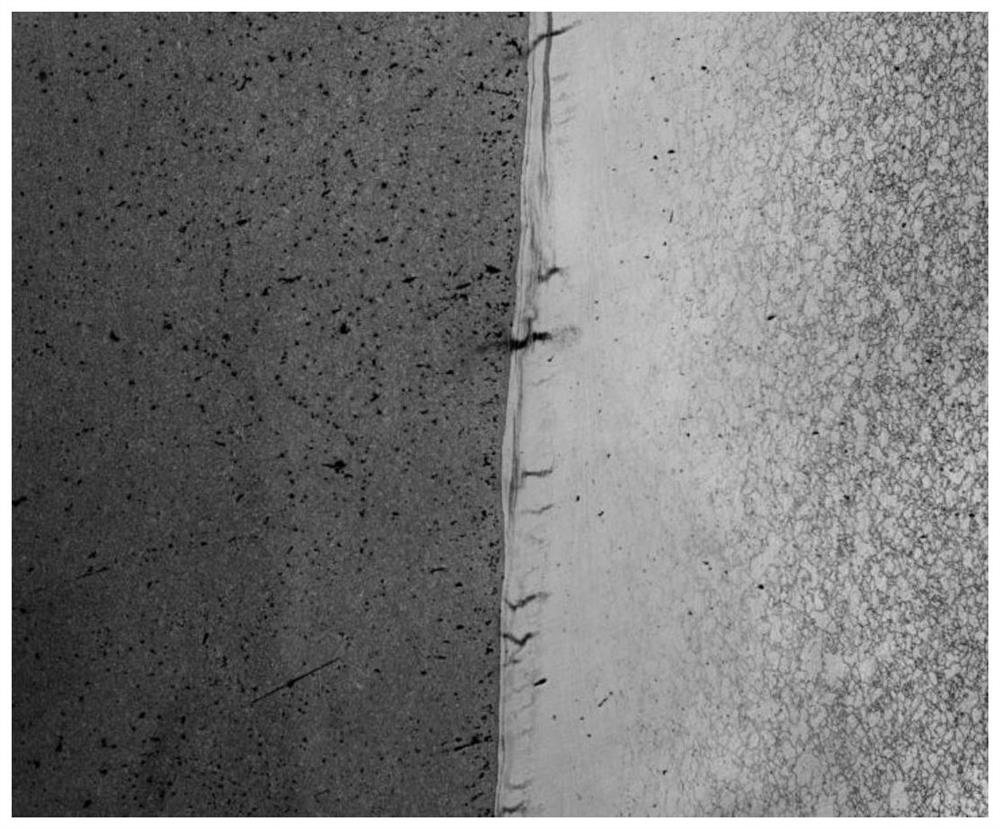

Image

Examples

Embodiment 1

[0049] This embodiment provides a method for welding ceramics and nickel-based alloys, comprising the following steps:

[0050] Step 1. Install the silicon carbide ceramic tube and the Incoloy 800H high-temperature nickel-based alloy tube on the friction welding equipment fixture respectively, and clamp the fixture so that there is no shaking, so that the center line of the silicon carbide ceramic tube and the high-temperature nickel-base alloy tube are at the same On the horizontal line, the welding surfaces of silicon carbide ceramic tubes and high-temperature nickel-based alloy tubes are cleaned of rust, scale and oil respectively; the outer diameters of silicon carbide ceramic tubes and high-temperature nickel-based alloy tubes are both 45mm, 9mm, the length is 0.3m;

[0051] Step 2. After mixing and drying the titanium powder and nickel powder by wet method, Ti / Ni mixed powder is obtained, and the Ti / Ni mixed powder is sprayed onto the welding surface of the silicon carbi...

Embodiment 2

[0064] This embodiment provides a method for welding ceramics and nickel-based alloys, comprising the following steps:

[0065] Step 1. Install the silicon carbide ceramic tube and the Incoloy 800H high-temperature nickel-based alloy tube on the friction welding equipment fixture respectively, and clamp the fixture so that there is no shaking, so that the center line of the silicon carbide ceramic tube and the high-temperature nickel-base alloy tube are at the same On the horizontal line, the welding surfaces of silicon carbide ceramic tubes and high-temperature nickel-based alloy tubes are cleaned of rust, scale and oil respectively; the outer diameters of silicon carbide ceramic tubes and high-temperature nickel-based alloy tubes are both 45mm, 9mm, the length is 0.3m;

[0066] Step 2. After mixing and drying the titanium powder and nickel powder by wet method, Ti / Ni mixed powder is obtained, and the Ti / Ni mixed powder is sprayed onto the welding surface of the silicon carbi...

Embodiment 3

[0079] This embodiment provides a method for welding ceramics and nickel-based alloys, comprising the following steps:

[0080]Step 1. Install the silicon carbide ceramic tube and the Incoloy 800H high-temperature nickel-based alloy tube on the friction welding equipment fixture respectively, and clamp the fixture so that there is no shaking, so that the center line of the silicon carbide ceramic tube and the high-temperature nickel-base alloy tube are at the same On the horizontal line, the welding surfaces of silicon carbide ceramic tubes and high-temperature nickel-based alloy tubes are cleaned of rust, scale and oil respectively; the outer diameters of silicon carbide ceramic tubes and high-temperature nickel-based alloy tubes are both 45mm, 9mm, the length is 0.3m;

[0081] Step 2. After mixing and drying the titanium powder and nickel powder by wet method, Ti / Ni mixed powder is obtained, and the Ti / Ni mixed powder is sprayed onto the welding surface of the silicon carbid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com