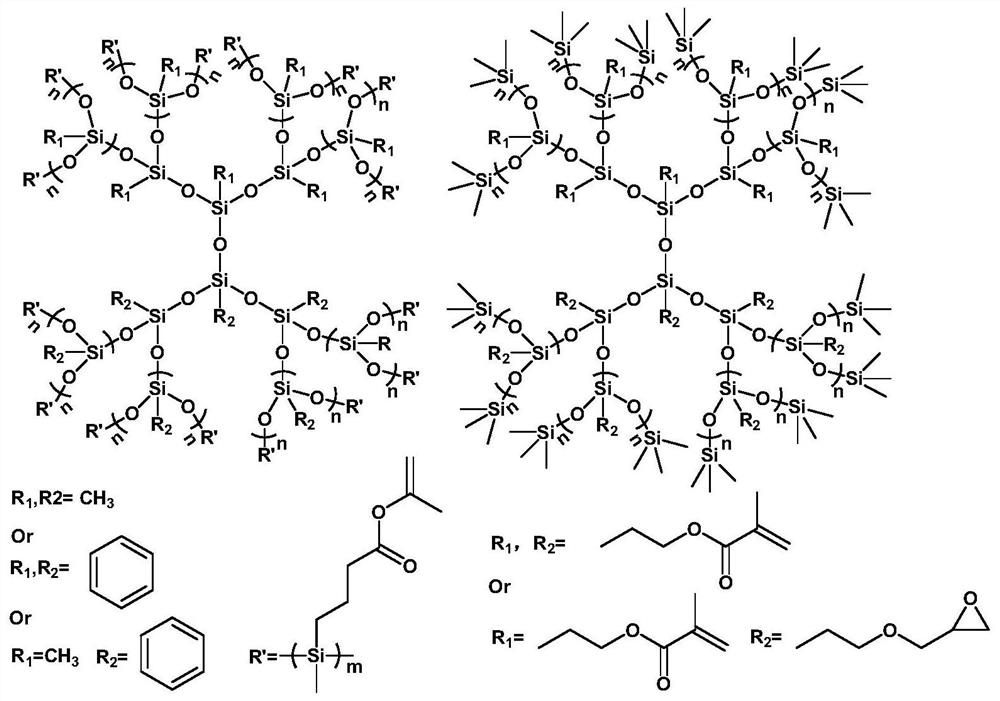

Hyperbranched polymer and preparation method thereof and application of hyperbranched polymer in preparation of electropolarized color-changing film

A hyperbranched polymer, color-changing film technology, applied in chemical instruments and methods, color-changing fluorescent materials, etc., can solve the problems of unsatisfactory minimum transmittance, complex processing technology, and limited application scenarios of smart glass technology, and achieve excellent The effect of fluidity and film-forming properties, high process repeatability, and wide discoloration range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of polyoctyl methacrylate: add 19.8g of isooctyl methacrylate (purchased from Hubei Nona Technology Co., Ltd.) and 100mL of ethyl acetate into a 250mL three-necked bottle, and after passing through nitrogen for 15min to remove the air, add 4mL of 1-hexanethiol, the temperature was raised rapidly to 75°C, and 328mg / 35mL of azobisisobutyronitrile (AIBN) in ethyl acetate was slowly added, and the reaction was stopped after 10h of reaction. After extraction, washing, rotary evaporation, and vacuum distillation to remove low-boiling fractions, polylauryl methacrylate is obtained. Its viscosity is 2100cps tested by rotational viscometer. 1 H-NMR (500MHz, CDCl 3 ,δ): 6.42-6.48(m,2H),3.99(m,2H),2.10(m,3H),0.90-1.60(m,15H).

[0053] The preparation method of polydecyl methacrylate is similar to that of polydecyl methacrylate. Finally, the viscosity of polydecyl methacrylate was 2300 cps. 1 H-NMR (500MHz, CDCl 3 ,δ): 6.40-6.50(m,2H),3.97(m,2H),2.01(m,3H)...

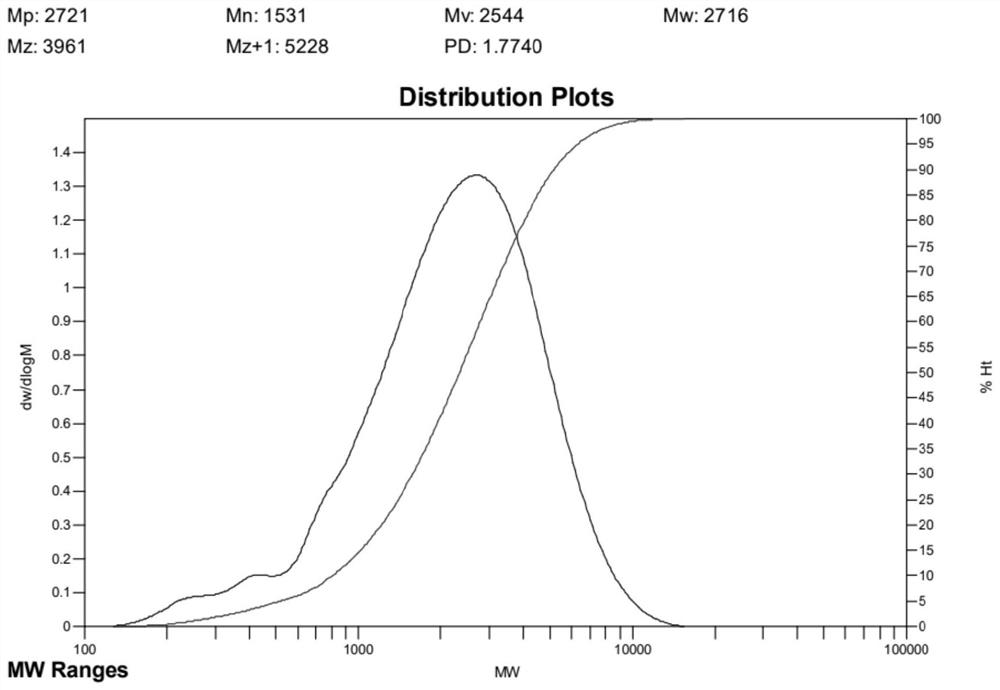

Embodiment 1

[0055] (1) Add 136.2g of methyltrimethoxysilane (purchased from Shanghai Macklin Biochemical Technology Co., Ltd.) and 18g of deionized water into a 500mL three-necked flask, stir well, then add glacial acetic acid dropwise into the three-necked flask solution until the pH value of the reaction system is 5.5. Then, the temperature was rapidly raised to 50° C., and after 4 hours of reaction, the temperature was lowered to end the reaction. The obtained crude product was extracted, rotated and evaporated, and the low-boiling point fraction was removed by vacuum distillation to obtain 105 g of P1 precursor. Its viscosity was measured with a rotational viscometer to be 4500cps.

[0056] (2) Add 100 g of P1 prepolymer and 300 mL of toluene into a 1 L three-necked flask, and blow nitrogen gas for 15 min. Then the temperature of the system was rapidly raised to 110° C., and 0.2 g of stannous octoate (purchased from Shanghai McLean Biochemical Technology Co., Ltd.) and 30 g of 3-met...

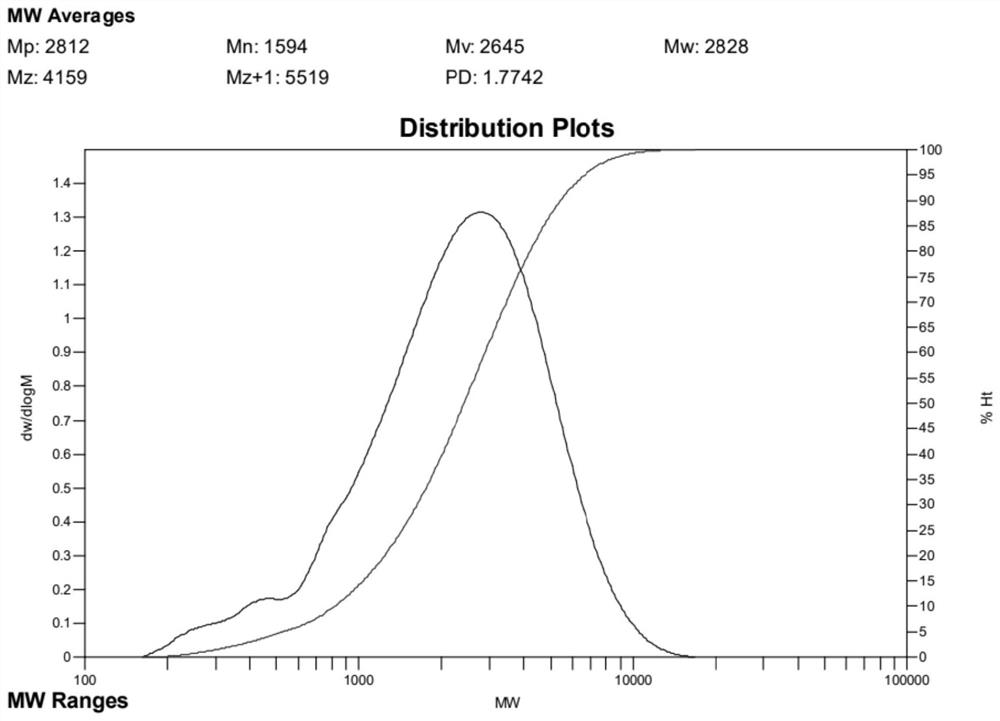

Embodiment 2

[0062] (1) Add 198g of phenyltrimethoxysilane (purchased from Jiande Zhiyou Silicon Materials Co., Ltd.) and 18g of deionized water into a 500mL three-necked flask, stir well, then add ice Acetic acid solution until the pH value of the reaction system is 5.5. Then, the temperature was rapidly raised to 50° C., and after 4 hours of reaction, the temperature was lowered to end the reaction. After the obtained crude product was extracted, rotated and evaporated, the low-boiling fraction was removed by vacuum distillation to obtain 150 g of P2 precursor. Its viscosity measured with a rotational viscometer is 5300cps.

[0063] (2) Add 100 g of P2 precursor and 300 mL of toluene into a 1 L three-necked flask, and blow nitrogen gas for 15 min. Then the temperature was raised rapidly to 110° C., 0.2 g of stannous octoate and 30 g of 3-methacryloxypropyldimethylmethoxysilane were added, and reacted for 4 hours, and then the reaction was stopped. After the reactant was cooled to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com