Liquid cooling charging cable and preparation method and application thereof

A charging cable and liquid cooling technology, applied in cable/conductor manufacturing, charging stations, insulated cables, etc., can solve problems such as short service life of cables, accelerated cable aging, and lack of heat dissipation devices, etc., to achieve improved current carrying capacity and low permeability , good softness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

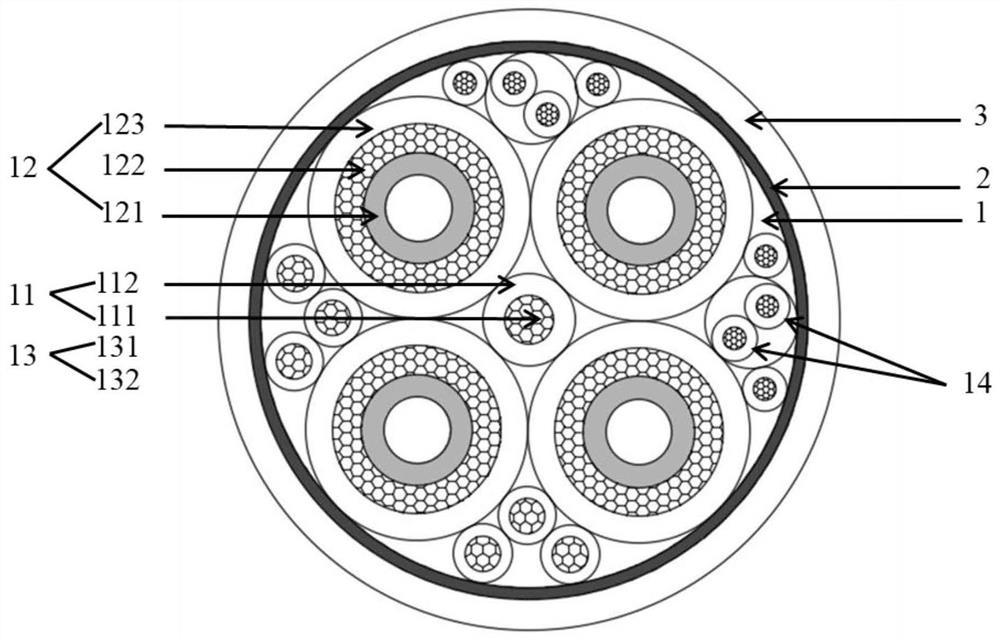

[0073] This embodiment provides a liquid-cooled charging cable and its preparation method. The structural schematic diagram of the liquid-cooled charging cable is as follows: figure 1 As shown, it includes a cable core 1, an isolation layer 2 and an outer sheath 3 in sequence from the inside to the outside in the radial direction;

[0074] The cable core 1 includes a ground wire core 11, four power wire cores 12, ten signal wire cores 13 and two sets of signal wire core groups 14;

[0075] The ground wire core 11 is located in the gap between the four power wire cores 12, and the ground wire core 11 includes a ground wire conductor 111 and a ground wire insulation 112 sequentially from inside to outside in the radial direction;

[0076] The material of the ground wire insulation 112 is a thermoplastic elastomer with a thickness of 0.5mm;

[0077] The power line core 12 includes a power line cooling pipe 121, a power line conductor 122 and a power line insulation 123 from insi...

Embodiment 2

[0093] This embodiment provides a liquid-cooled charging cable and its preparation method. The structural schematic diagram of the liquid-cooled charging cable is as follows: figure 1 Shown, the difference with embodiment 1 is:

[0094] The thickness of the ground wire insulation 112 is 0.7mm, the thickness of the power line cooling pipe 121 is 1.0mm, the diameter of the copper monofilament in the copper-graphene composite material is 0.05mm, and the thickness of the power line insulation 123 is 0.9mm, so The thickness of the signal line insulation 132 is 0.5mm, the thickness of the isolation layer 2 is 0.06mm, and the thickness of the outer sheath 3 is 2.5mm;

[0095] The working temperature of the extruder head in step (2) is 170°C, and the working temperature of the neck is 175°C; the extruder body includes a first zone, a second zone, and a third zone connected in sequence and the fourth zone; the working temperature of the first zone is 150°C, the working temperature of ...

Embodiment 3

[0098] This embodiment provides a liquid-cooled charging cable and its preparation method. The structural schematic diagram of the liquid-cooled charging cable is as follows: figure 1 Shown, the difference with embodiment 1 is:

[0099] The thickness of the ground wire insulation 112 is 0.6mm, the thickness of the power line cooling pipe 121 is 0.8mm, the diameter of the copper monofilament in the copper-graphene composite material is 0.15mm, and the thickness of the power line insulation 123 is 0.7mm, so The thickness of the signal line insulation 132 is 0.45mm, the thickness of the isolation layer 2 is 0.07mm, and the thickness of the outer sheath 3 is 2mm;

[0100] The working temperature of the extruder head in step (2) is 175°C, and the working temperature of the neck is 180°C; the extruder body includes a first zone, a second zone, and a third zone connected in sequence and the fourth zone; the working temperature of the first zone is 160°C, the working temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com