Efficient microwave excitation gas discharge equipment

A gas discharge and microwave technology, applied to electrical components, plasma, etc., can solve problems such as difficulty in achieving optimal working conditions, reduced energy efficiency, and reduced energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

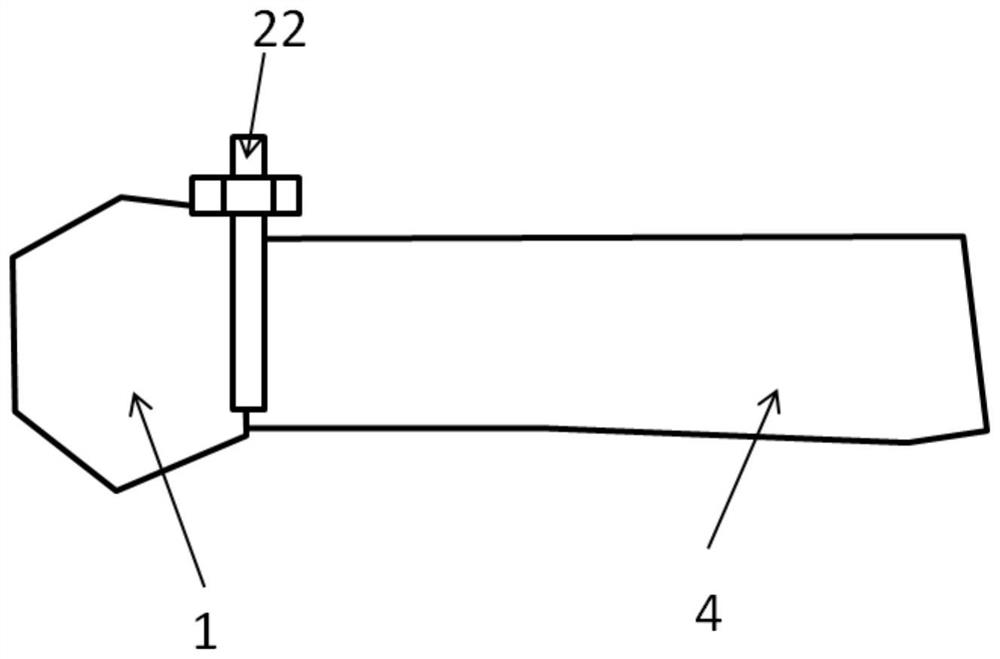

[0034] Such as figure 1 shown.

[0035] A high-efficiency microwave-excited gas discharge device, including a microwave source 1 with an operating frequency of f0 and a micro-nonlinear device 4 connected in sequence; the micro-non-linear device 4 has two state, a small signal state and a large signal state; a coupling structure 22 is arranged between the microwave source 1 and the micro nonlinear device 4; the coupling structure 22 has two states, and the coupling structure 22 The first state corresponds to a weak coupling state, and the second state of the coupling structure 22 corresponds to a strong coupling state; after the micro nonlinear device 4 changes from a small signal state to a large signal state, the coupling structure 22 switch between the first state and the second state.

[0036] There is gas inside the micro-nonlinear device 4, which can break down and generate plasma under the action of sufficiently high-power microwaves.

[0037] The coupling structure 2...

Embodiment 2

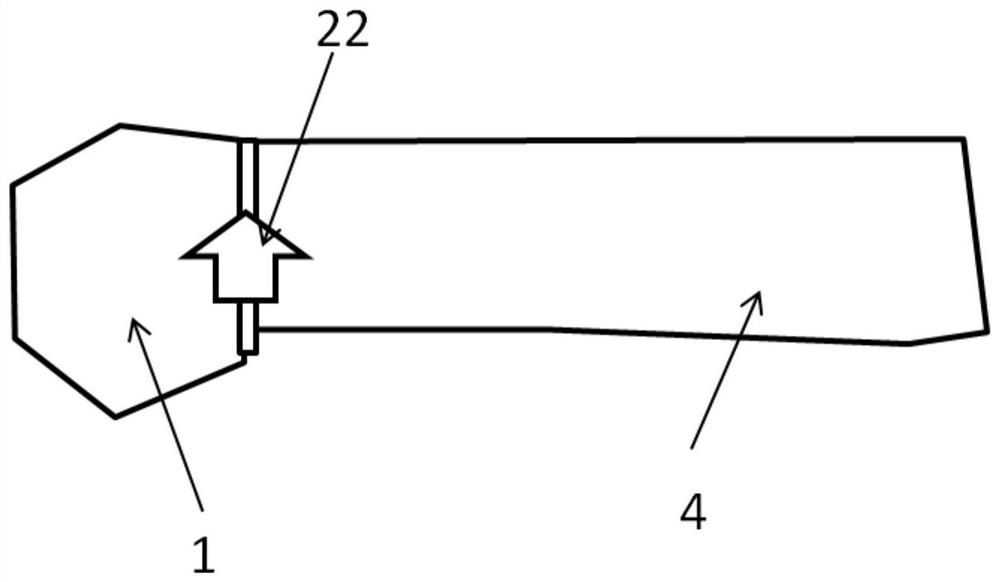

[0040] Such as figure 2 shown.

[0041] Compared with implementation example 1, the only difference is:

[0042] The coupling structure 22 is a diode.

Embodiment 3

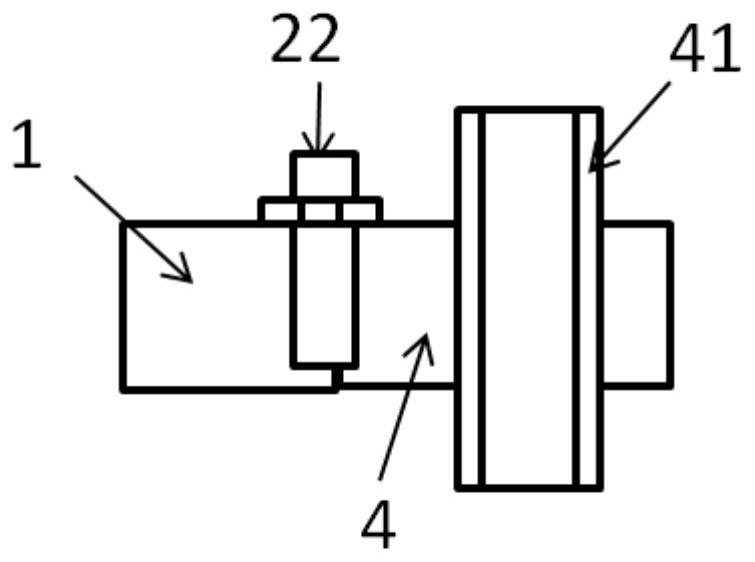

[0044] Such as image 3 shown.

[0045] Compared with implementation example 1, the only difference is:

[0046] The high-efficiency microwave excited gas discharge device is a plasma torch. Both the output end of the microwave source and the nonlinear device 4 are rectangular waveguides. A dielectric tube 41 is arranged in the rectangular waveguide, and the dielectric tube 41 passes through the waveguide. In the waveguide, gas is input from one end of the dielectric tube 41 , is ionized through the dielectric tube 41 , forms high-temperature plasma, and is ejected from the other end of the dielectric tube 41 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com