Subcritical composite solvent extraction separation method for multiple components in flaxseed meal

A separation method and flaxseed meal technology are applied in the field of subcritical compound solvent extraction and separation of various active ingredients in flaxseed meal, and achieve the effects of reducing operation units, reducing environmental burden and reducing hazard risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

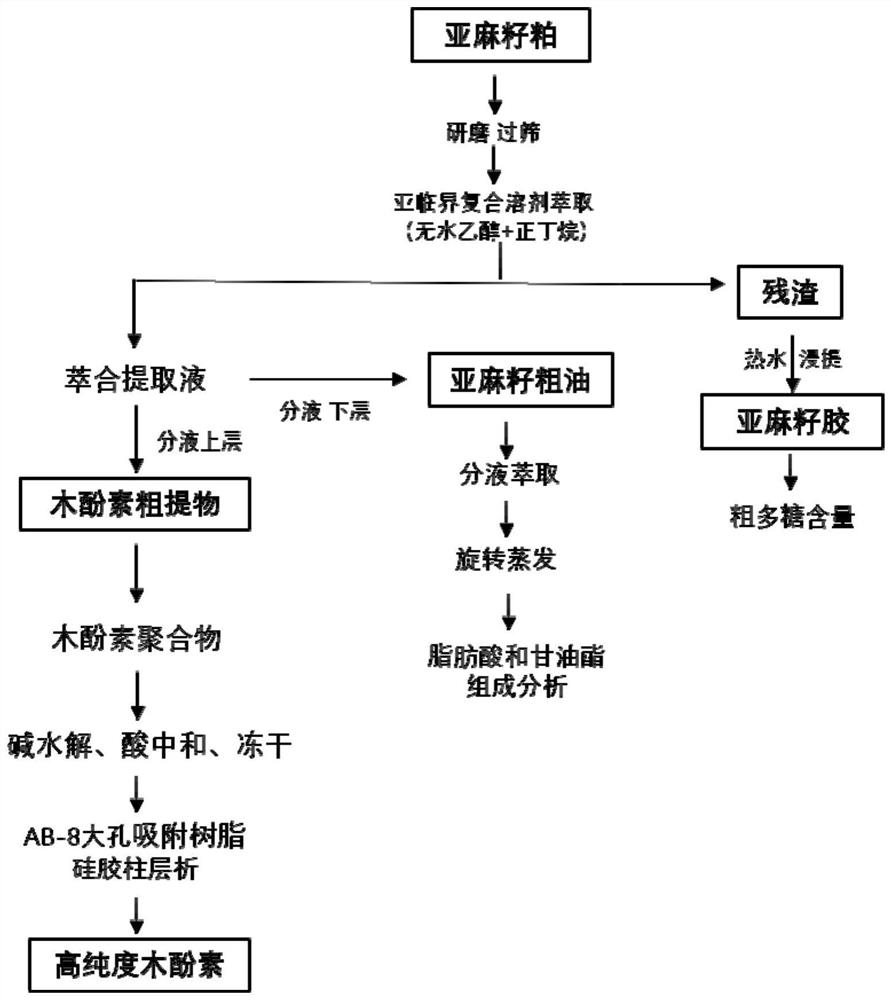

[0053] A subcritical composite solvent extraction and separation method for various components of linseed meal comprises the following steps:

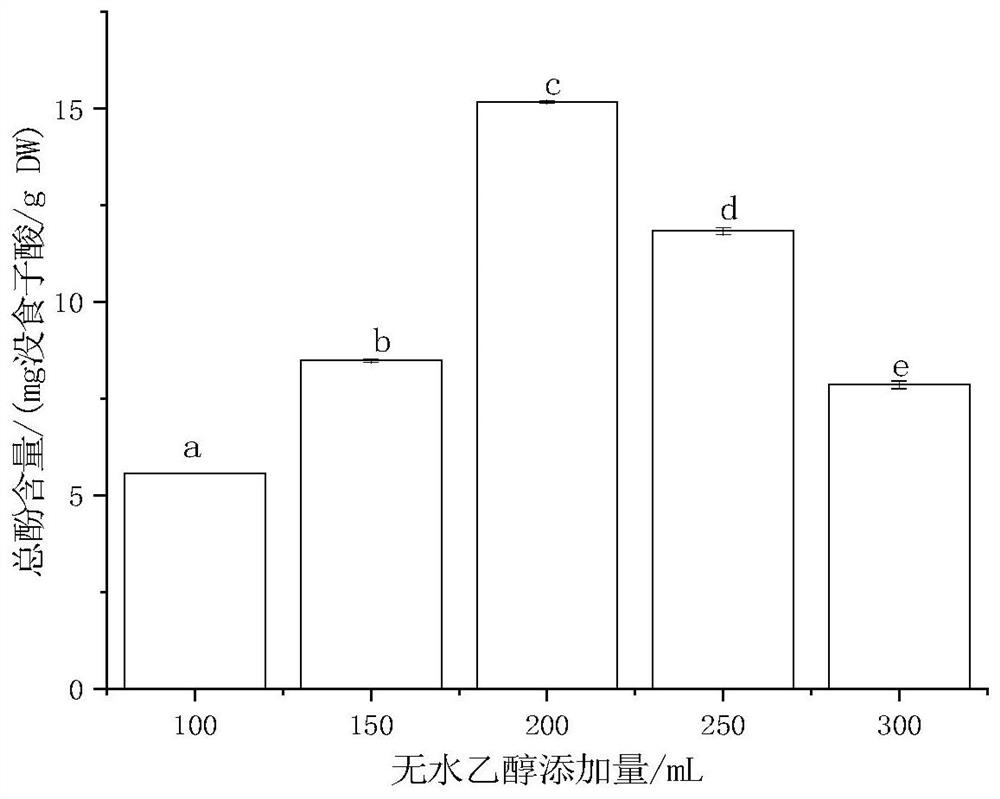

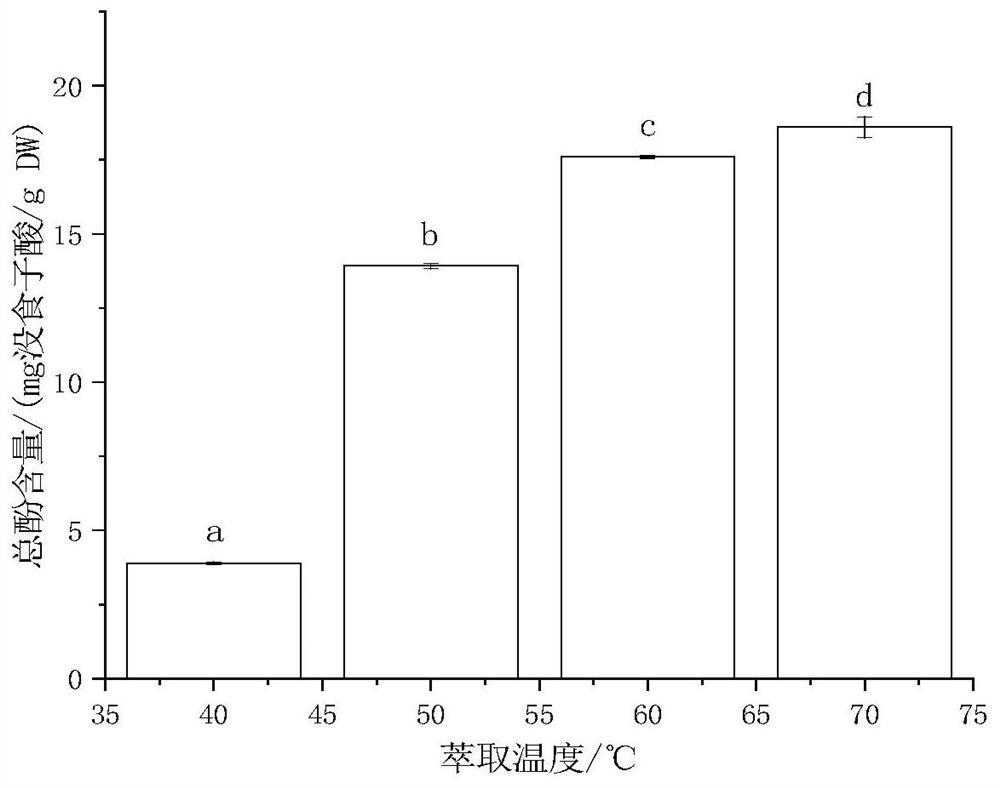

[0054] (1) Weigh 10.0g of ground flaxseed meal powder and place it in the extraction bag in the subcritical extraction kettle, add 200mL of n-butane, conduct a single factor test of extraction conditions, explore different composite solvents (n-butane and absolute ethanol) ratio ( figure 2 ), extraction temperature ( image 3 ), extraction time ( Figure 4 ) on the total phenol content, according to the results of the single factor optimal value, the response surface design experiment was carried out, and the optimal conditions of subcritical extraction were obtained as the composite solvent ratio of 1:1 (n-butane and absolute ethanol), and the extraction temperature was 69°C , the extraction time was 2h, and the total phenol content of the obtained sample was 22.76mg GAE / g.

[0055] After extraction, the upper layer of the extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com