Coating for rusted coating of surfaces of rusted hot-dip galvanized steel structures

A steel structure and hot-dip galvanizing technology, which is applied to the surface coating liquid device, anti-corrosion coating, polyether coating, etc., can solve the problems of unguaranteed performance, uneven quality, and heavy metal content, and achieve low shrinkage , strong adhesion, and the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

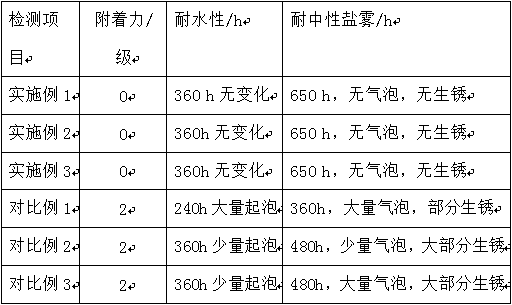

Examples

Embodiment 1

[0018] A kind of coating that is used for rust coating on the surface of corroded hot-dip galvanized steel structure, said coating material comprises coating A and coating B, wherein said coating A is made up of following components: lauric acid 5 parts, epoxy resin 20 part, 42 parts of reduced zinc powder, 20 parts by weight of xylene, 2 parts of ethanol, 4 parts of organobentonite, 5 parts of hectorite, and 25 parts of water; wherein said coating B consists of the following components: polyepoxysuccinic acid 7 5 parts, 5 parts of silicate, 2 parts of molybdate, 14 parts of ethylene glycol, 6 parts of sodium N-lauroyl sarcosinate, 12 parts of acrylic acid emulsion, 5 parts of water, and the above-mentioned parts are parts by weight.

[0019] The method of using the above coatings for steel structure anticorrosion is as follows:

[0020] (1) Remove floating rust and dust on the surface of the steel structure;

[0021] (2) Mix the components in paint A evenly, spray it on the ...

Embodiment 2

[0024] A kind of coating that is used for rusty coating on the surface of corroded hot-dip galvanized steel structure, said coating material comprises coating A and coating B, wherein said coating A is made up of following components: 8 parts of lauric acid, 12 parts of epoxy resin part, 53 parts of reduced zinc powder, 10 parts by weight of xylene, 5 parts of ethanol, 2 parts of organic bentonite, 10 parts of hectorite, and 20 parts of water; wherein said coating B is made up of the following components: polyepoxysuccinic acid 9 parts, 3 parts of silicate, 4 parts of molybdate, 12 parts of ethylene glycol, 9 parts of sodium N-lauroyl sarcosinate, 8 parts of acrylic acid emulsion, and 8 parts of water, all of which are parts by weight.

[0025] The method of using the above coatings for steel structure anticorrosion is as follows:

[0026] (1) Remove floating rust and dust on the surface of the steel structure;

[0027] (2) Mix the components in paint A evenly, spray on the s...

Embodiment 3

[0030] A kind of paint that is used for rusty coating on the surface of corroded hot-dip galvanized steel structure, said coating material includes paint A and paint B, wherein said paint A is made up of following components: 6 parts of lauric acid, 16 parts of epoxy resin part, 48 parts of reduced zinc powder, 15 parts by weight of xylene, 4 parts of ethanol, 3 parts of organic bentonite, 8 parts of hectorite, 22 parts of water; wherein said coating B is made up of following components: polyepoxysuccinic acid 8 parts, 4 parts of silicate, 3 parts of molybdate, 13 parts of ethylene glycol, 8 parts of sodium N-lauroyl sarcosinate, 10 parts of acrylic acid emulsion, 6 parts of water, and the above-mentioned parts are parts by weight.

[0031] The method of using the above coatings for steel structure anticorrosion is as follows:

[0032] (1) Remove floating rust and dust on the surface of the steel structure;

[0033] (2) Mix the components in paint A evenly, spray it on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com