Preparation method suitable for industrial scale-up production of mannitol eutectic auxiliary material

A technology of mannitol and crystal excipients, which is applied in the field of medicine, can solve the problems of uneven appearance, complicated process, and low yield, and achieve the effect of simple and easy control of the process, good repeatability, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (a) Weigh mannitol powder and solid particles of calcium chloride with a molar ratio of 1:1, and add a certain proportion of ethanol-water solvent

[0025] Weigh 18.24g mannitol and 11.1g anhydrous calcium chloride, add in 250mL solvent (water:ethanol=8:92) to obtain suspension;

[0026] (b) Stir at a constant speed for more than 2 hours at a certain temperature;

[0027] Stir the aforementioned suspension at 25°C for 6 hours at a stirring speed of 200rpm;

[0028] (c) Suction filtration under reduced pressure on the suspension obtained in the previous steps, and drying the obtained solid product to obtain the eutectic

[0029] The suspension obtained in step (b) was subjected to vacuum suction filtration, and the obtained white solid was dried at 40° C. to obtain a solid sample of mannitol calcium chloride cocrystal.

Embodiment 2

[0031] (a) Weigh mannitol powder and solid particles of calcium chloride with a molar ratio of 1:1, and add a certain proportion of ethanol-water solvent

[0032] Weigh 18.24g mannitol and 11.1g anhydrous calcium chloride, add in 250mL solvent (water:ethanol=1:9) to obtain suspension;

[0033] (b) Stir at a constant speed for more than 2 hours at a certain temperature;

[0034] Stir the suspension at 30°C for 4 hours at a stirring speed of 200 rpm;

[0035] (c) Suction filtration under reduced pressure on the suspension obtained in the previous steps, and drying the obtained solid product to obtain the eutectic

[0036] The suspension obtained in step (b) was subjected to vacuum suction filtration, and the obtained white solid was dried at 40° C. to obtain a solid sample of mannitol calcium chloride cocrystal.

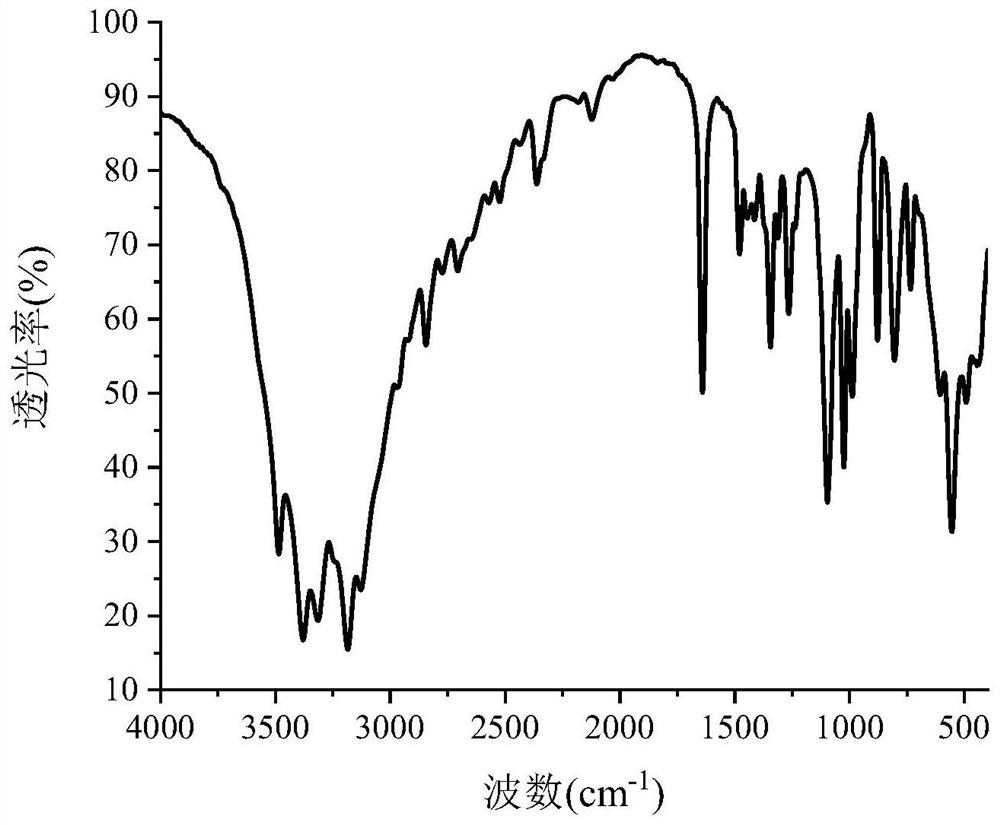

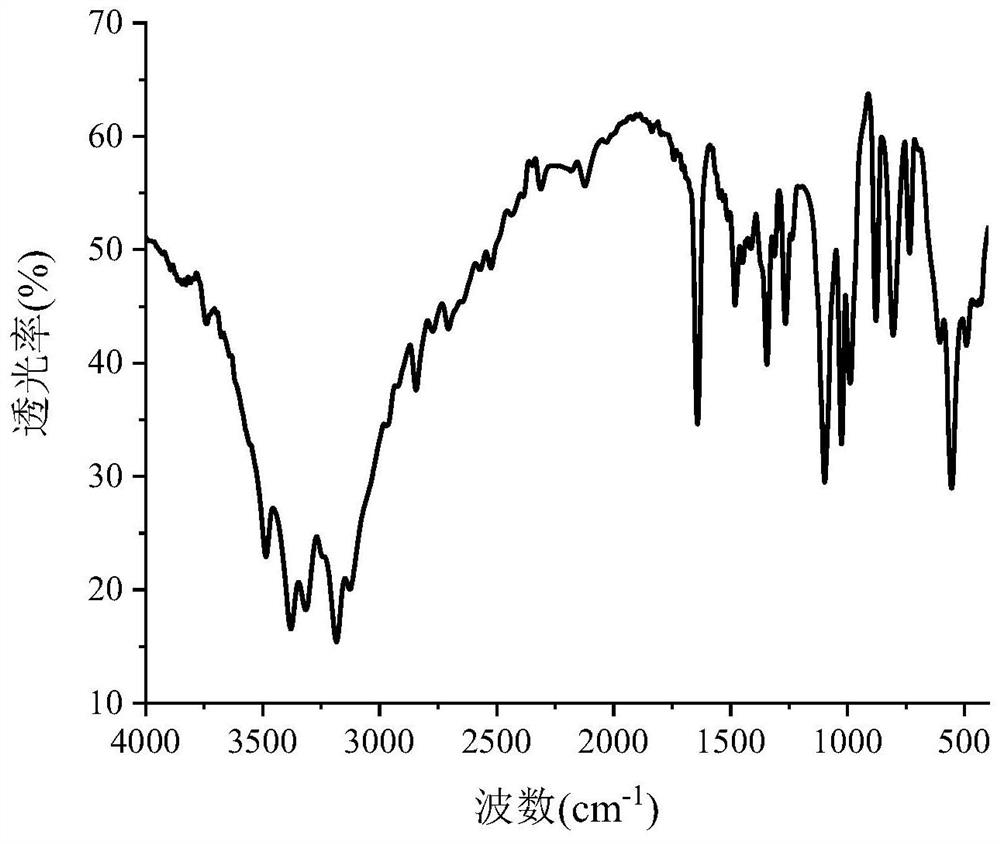

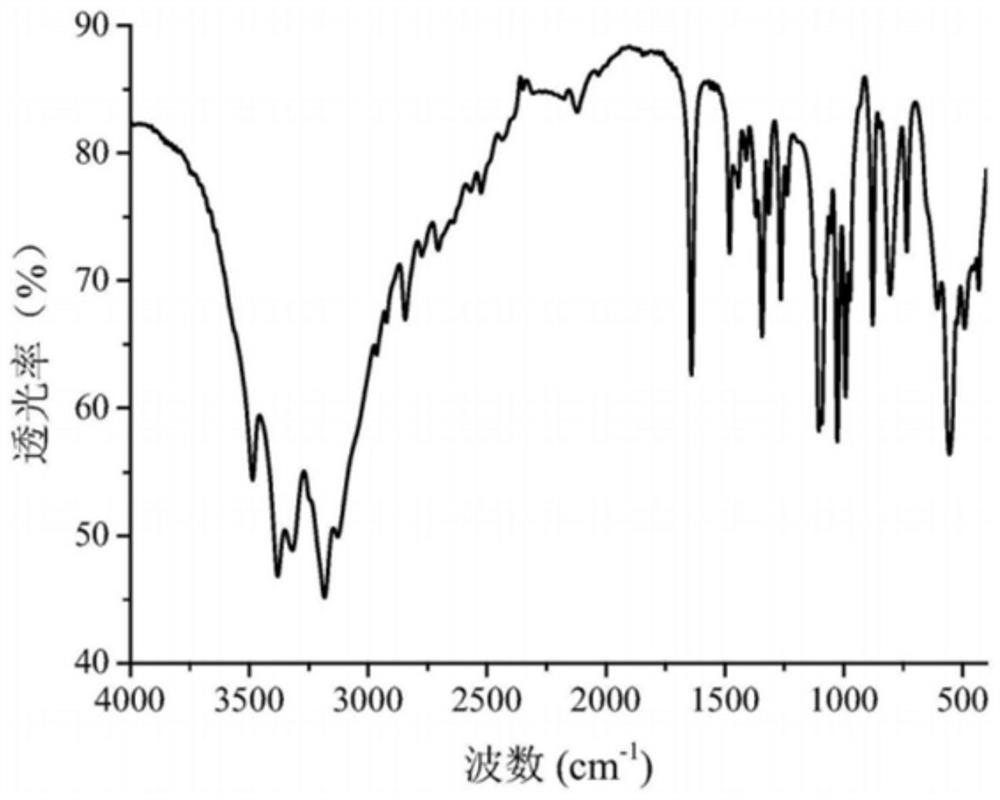

[0037] The mannitol calcium chloride eutectic that embodiment 1-2 makes adopts FT-IR spectroscopic characterization, and spectrogram sees attached Figure 1-2 , whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com