Manufacturing method of silicon pressure sensor chip of beam film structure

A technology of sensor chip and manufacturing method, which is applied to the measurement of the property and force of piezoelectric resistance materials, etc., can solve the problems of depth error and difficulty in obtaining beam film thickness, etc., and achieve improved consistency, simple operation, and clear production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

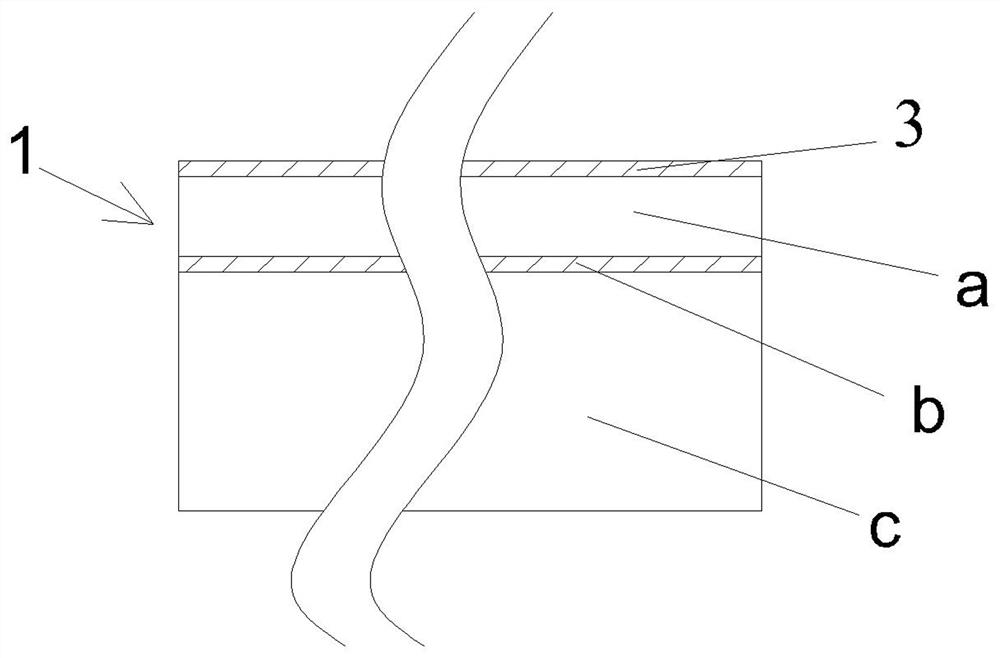

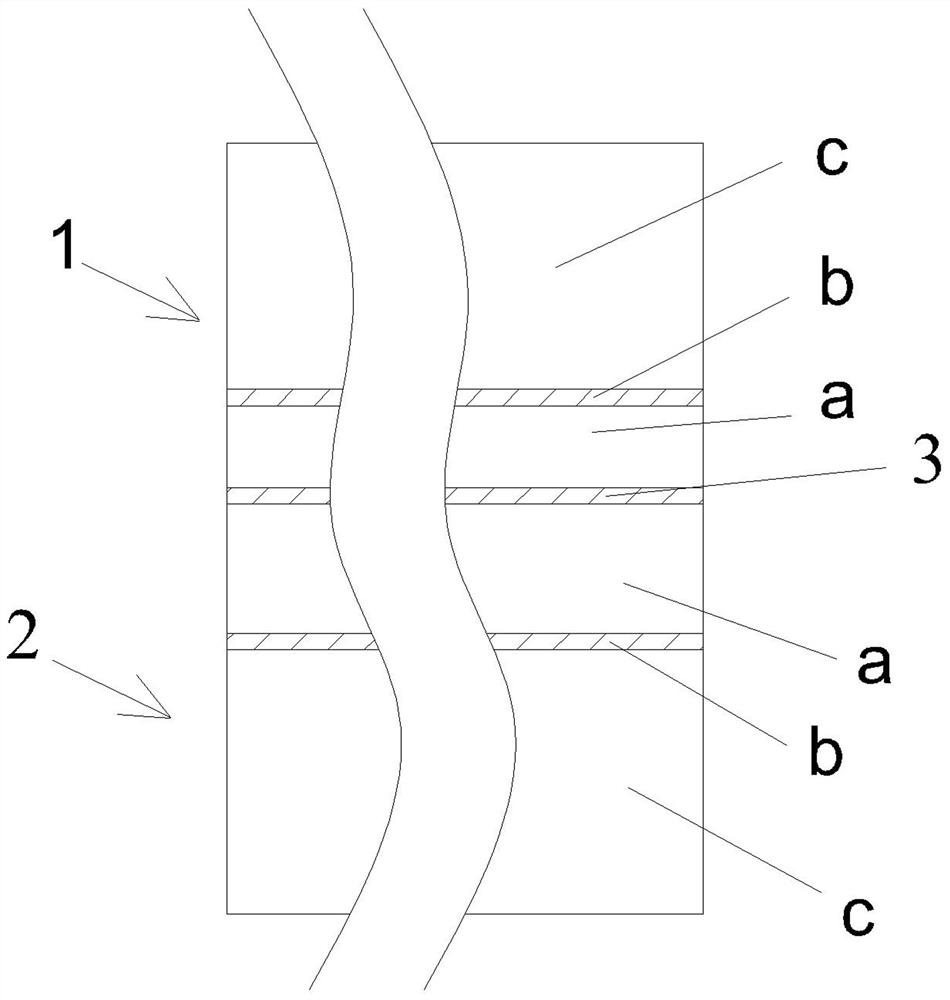

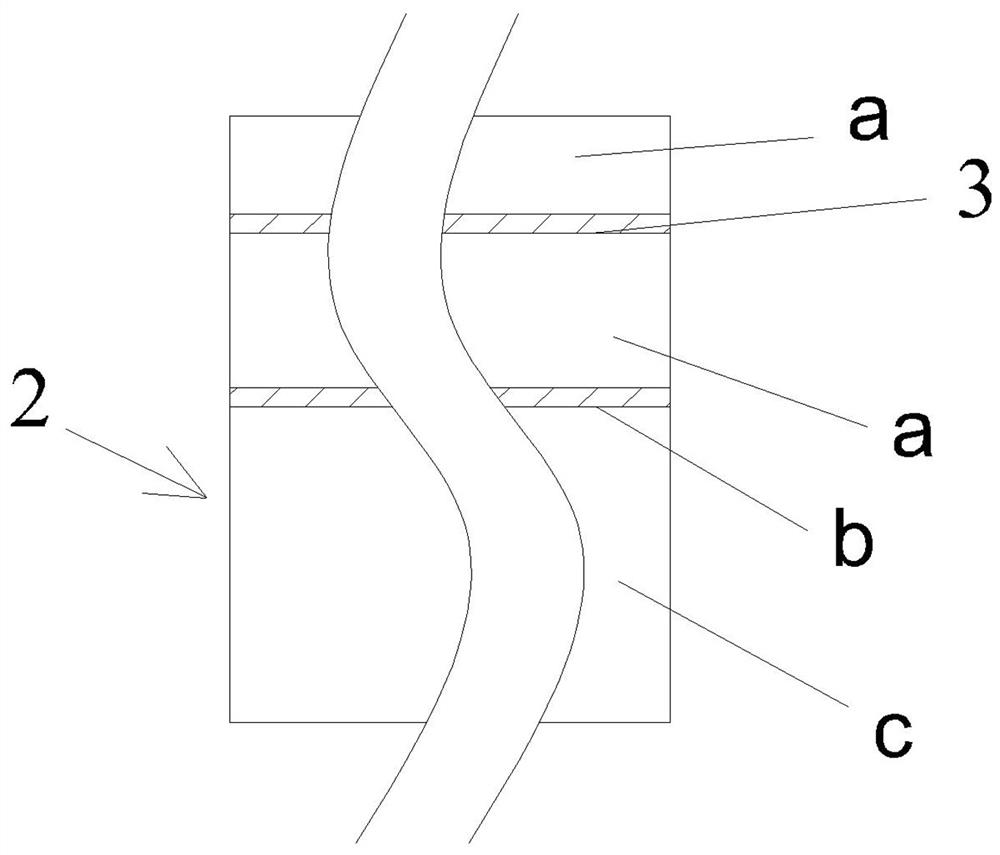

[0028] like Figure 1-9 As shown, a silicon pressure sensor chip manufacturing method with a beam-membrane structure includes the following steps: a) bonding the first silicon wafer and the second silicon wafer, and selecting two SOI silicon wafers as the first silicon wafer 1 and the second silicon wafer The second silicon wafer 2, the first and second silicon wafers have the same structure and both include a top layer of silicon a, a buried oxide layer b and a bottom layer of silicon c. On the top layer of silicon a of the first silicon wafer, an oxide layer 3 is prepared by performing a thermal oxidation process, and the oxide layer 3 and the top layer of silicon a of the second silicon wafer 2 are used as bonding surfaces to perform silicon-silicon dioxide bonding. Bonding, that is, bonding the second silicon chip 2 to the oxide layer 3 of the first silicon chip.

[0029] b) Thinning of the first silicon wafer, the buried oxide layer b and the underlying silicon c of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com